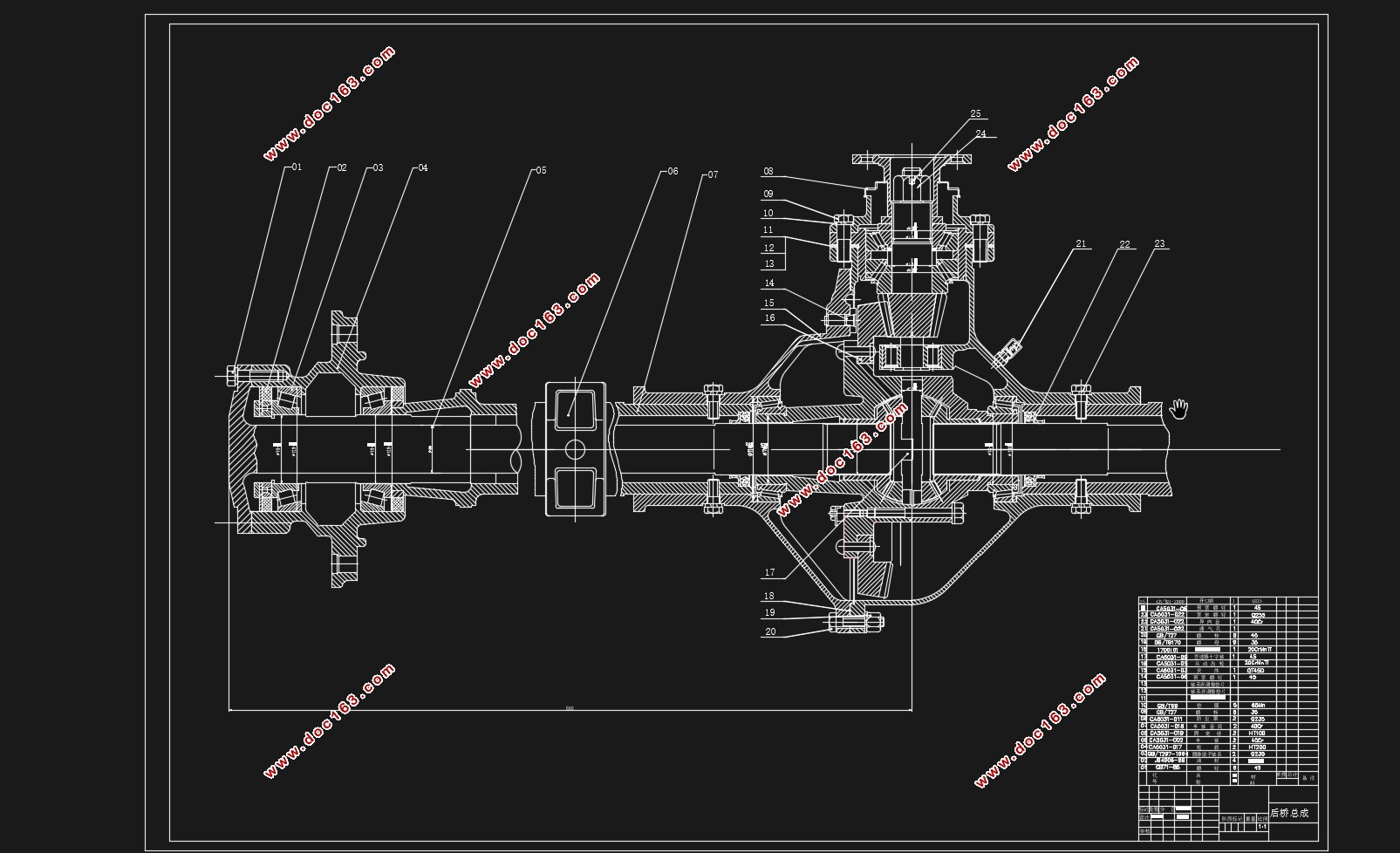

8米轻型客车后桥总成设计(含CAD零件图装配图)

8米轻型客车后桥总成设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,文献摘要,论文说明书11900字,CAD图5张,PDF图5张)

摘 要

后桥是汽车各种组合部件中非常重要的一环,它的能力将会对客车的使用性能产生积极或消极的作用。后桥的主要作用是加大由汽车变速器和传动轴传导过来的转矩,并将一同传来的转速降低后传给其所连接的车轮,同时汽车整体所遭受的各个方向的力也将由后桥来承担。通过设计一个经济适用的后桥,可以大大提升汽车动力性行驶性等各项性能。

本次对后桥的设计计算有以下几项:主减速器的设计计算、差速器的设计计算、半轴的设计计算和驱动桥壳受力分析。主减速器的形式选择为单级主减速器;差速器形式选择普通圆锥齿轮差速器;传动装置选择全浮式半轴;桥壳则选用整体式桥壳。计算完毕后,将会使用AutoCAD 和SolidWorks等绘图软件绘制出客车后桥的总装配图和部分零件图,以便于制作。

关键词:后桥;主减速器;差速器;半轴;桥壳

Abstract

Rear axle is one of the most important assembiles of the automobile. Its performance directly influences the performance of buses. The basic functions of the rear axle is to increase the torque torque which comes from the drive shaft and transmission, also reduce the rotation speed and transfer them to the left and right wheels. Rear axle also can bear the vertical force, lengthways force and transversals force which come from the ground, carframe and the body of car. With designing a suitable and affordable rear axle, the power performance, trafficability characteristic and safety of the bus can be improved greatly.

[资料来源:Doc163.com]

In this report, the design of rear axle contains the design of main reducer, differential mechanism, transmitted apparatus and the housing of driving axle. The main reducer we will use single reduction gear, the differential mechanism will use common taper planet gear. The transmission apparatus will adopt full floating axle shaft and the housing of driving axle will use the whole pattern. After the calculating, we will use AutoCAD, Solidworks and other softwares to draw the assembly drawing and some part drawing of the bus rear axle, in order to manufacture easily.

Key Words:Rear axle; main reducer; differential mechanism; half shaft; housing

[版权所有:http://DOC163.com]

目录

第1章绪论 1

1.1客车后桥简介 1

1.2国内外客车后桥研究状况 1

1.3客车后桥设计的要求 1

第2章后桥的结构形式及选择 3

2.1后桥结构形式 3

2.2主减速器的结构形式 3

2.3差速器的结构形式 5

2.4传动装置的结构形式 6

2.5桥壳的结构形式 6

第3章后桥设计计算 7

3.1主减速器设计计算 7

3.1.1主减速比的确定 7

3.1.2主减速器齿轮载荷计算 8

3.1.3主减速器齿轮基本参数选择 10

3.1.4主减速器锥齿轮的材料 12

3.1.5主减速器锥齿轮尺寸计算 12

3.1.6主减速器齿轮的强度计算 15

3.2差速器的计算 19

3.2.1差速器齿轮主要参数选择 19

3.2.2差速器齿轮的材料 20 [来源:http://www.doc163.com]

3.2.3差速器齿轮几何尺寸计算 21

3.2.4差速器齿轮强度计算 23

3.3全浮式半轴的设计 25

3.3.1半轴基本参数计算及校核 25

3.3.2半轴花键设计、材料选取及热处理方法 26

3.4驱动桥壳设计 26

3.4.1桥壳的结构形式 26

3.4.2桥壳的受力与强度校核 27

第4章总结与展望 29

参考文献 30

致谢 31 [来源:http://www.doc163.com]

上一篇:城市SUV前轮制动器设计(含CAD零件装配图,CATIA三维图)