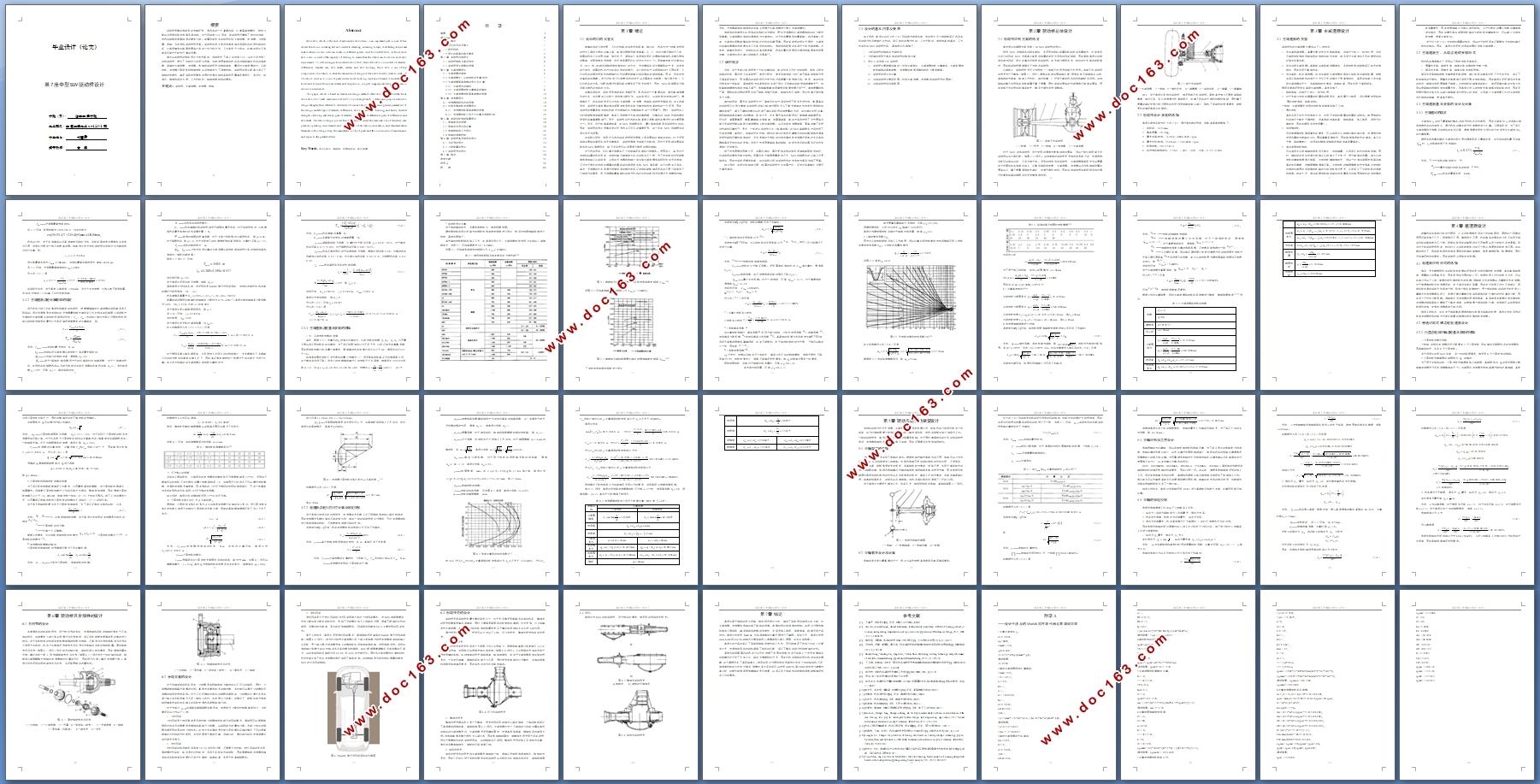

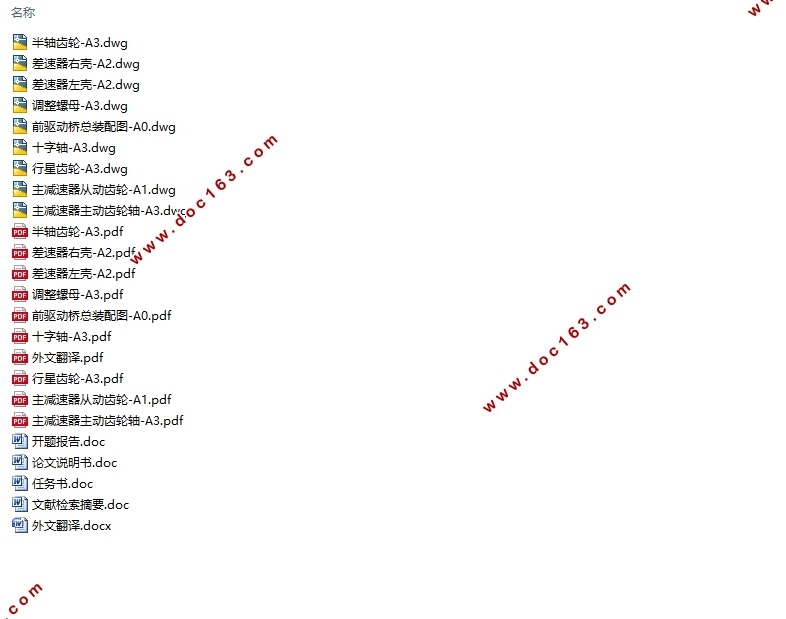

某7座中型SUV驱动桥设计(以汉兰达为例)(含CAD零件图装配图)

某7座中型SUV驱动桥设计(以汉兰达为例)(含CAD零件图装配图)(任务书,开题报告,外文翻译,文献摘要,论文说明书15800字,CAD图9张)

摘要

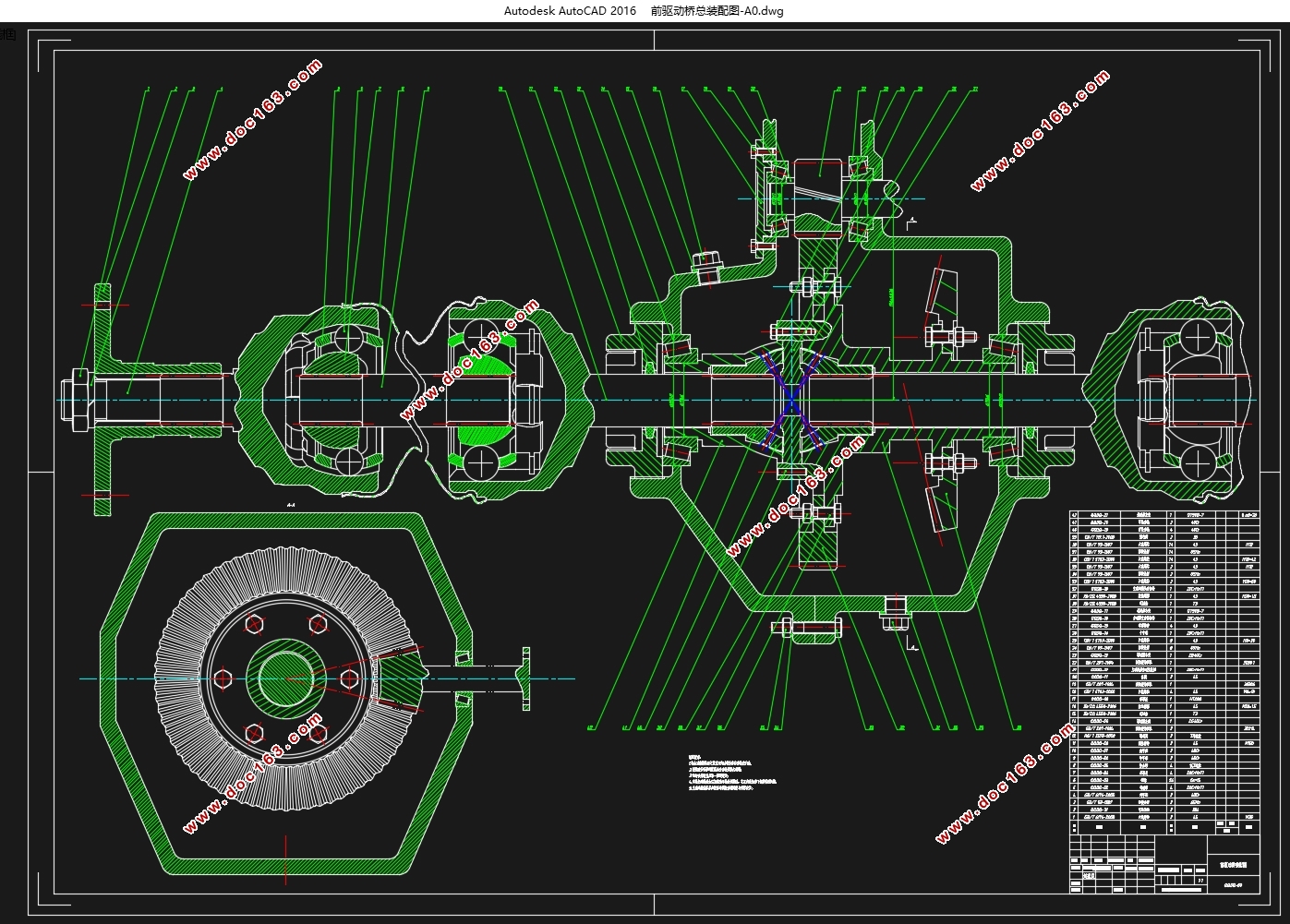

驱动桥是整车传动系的末端环节,是汽车的一个重要总成,它兼具减速增扭、转矩分配以及两侧车轮差速等多项功能。对于四驱型SUV而言,前驱动桥还增加了转向的功能,使汽车能够按照驾驶员的要求行驶。前置四驱汽车的前桥包括主减速器、差速器、分动装置、半轴、万向节和驱动桥桥壳等。驱动桥的设计是否合理直接关系到汽车使用性能的好坏,它承受着来自路面和悬架之间的一切力和力矩,工作条件十分恶劣,轻微的设计不当都有可能产生较为严重的后果。

本文以驱动桥的传统设计方法为基础,详细研究了某7座中型SUV(以汉兰达为例)的前驱动桥,提出了比较可行的设计思路,并参考同类型的汽车有关结构确定汽车总体参数,再确定主减速器、差速器、半轴和驱动桥壳的结构类型,最后对主减速器的主、从动齿轮、差速器行星齿轮和半轴齿轮以及半轴进行了强度校核。驱动桥的设计基本上保证了结构的合理性,满足实际使用要求的同时使得总成和零部件尽量满足通用化、系列化、标准化、修理和保养方便、工艺性较好、制造难度较低的要求。

关键词:驱动桥;主减速器;差速器;半轴

[来源:http://www.doc163.com]

Abstract

Drive axle, which is the end of automotive drive train, is an important part in a car. It has several functions including but not limited to retarding, increasing torque, distributing torque and enable wheels on two sides can rotate in different speeds. And for a 4WD SUV, its front drive axle is also in need of the capacity of steering to ensure that the vehicle can be driven as driver’s requirement. To a front-engine four-wheels-drive SUV, front drive axle is consisted of retarder, differential, transfer case, axle shafts, cardan and axle housing. Drive axle is one of key components of a vehicle, so that the rationality of design of drive axle directly relate to usability of vehicle. And as it is one of parts under worst working conditions because it undertakes all forces and torques from road surface and suspension, a slight inappropriate design will lead to serious consequences.

This paper, which is based on traditional design method of the drive axle, studied the front drive axle of a 7-seats medium-sized SUV (Toyota Highland) in detail and propose a feasible design thought, then referred to structures of similar vehicles to determine general parameters of the design and the type of retarder, differential, axle shaft and axle housing, and finally checked strength of driving and driven gear of retarder, planetary and differential gear of differential and axle shaft. The whole design process fundamentally ensured the reasonability of structure, met practical operating requirements and requirements of utilization, serialization and standardization. Meanwhile this design keep the manufacturability of parts and the convenience of maintenance and repair to the greatest extent.

[来源:http://Doc163.com]

Key Words:drive axle;retarder;differential;axle shaft

驱动桥设计参数的选择

本设计参考车型为汉兰达2.0T,通过查阅相关资料,选取其基本参数如下:

1. 前轮距:1635mm;

2. 整备质量:2070kg;

3. 最大功率/转速:162kw/(4800-5600)rpm

4. 最大扭矩/转速:350N•m/(1700-4000)rpm

5. 轮胎规格:245/55 R19

6. 前进挡各档传动比:3.300、1.900、1.420、1.000、0.713、0.608

[资料来源:Doc163.com]

目 录

摘要 I

Abstract II [版权所有:http://DOC163.com]

第1章 绪论 1

1.1 设计的目的及意义 1

1.2 研究现状 2

1.3 设计的基本内容及要求 3

第2章 驱动桥总体设计 4

2.1 驱动桥结构方案的选定 4

2.2 驱动桥设计参数的选择 5

第3章 主减速器设计 6

3.1 主减速器的类型 6

3.2 主减速器主、从动齿轮的支撑形式 7

3.3 主减速器基本参数的设计及计算 7

3.3.1 主减速比的确定 7

3.3.2 主减速器齿轮计算载荷的确定 8

3.3.3 主减速器齿轮基本参数的选择 10

第4章 差速器设计 18

4.1 差速器结构形式的选择 18

4.2 对称式锥齿轮差速器设计 18

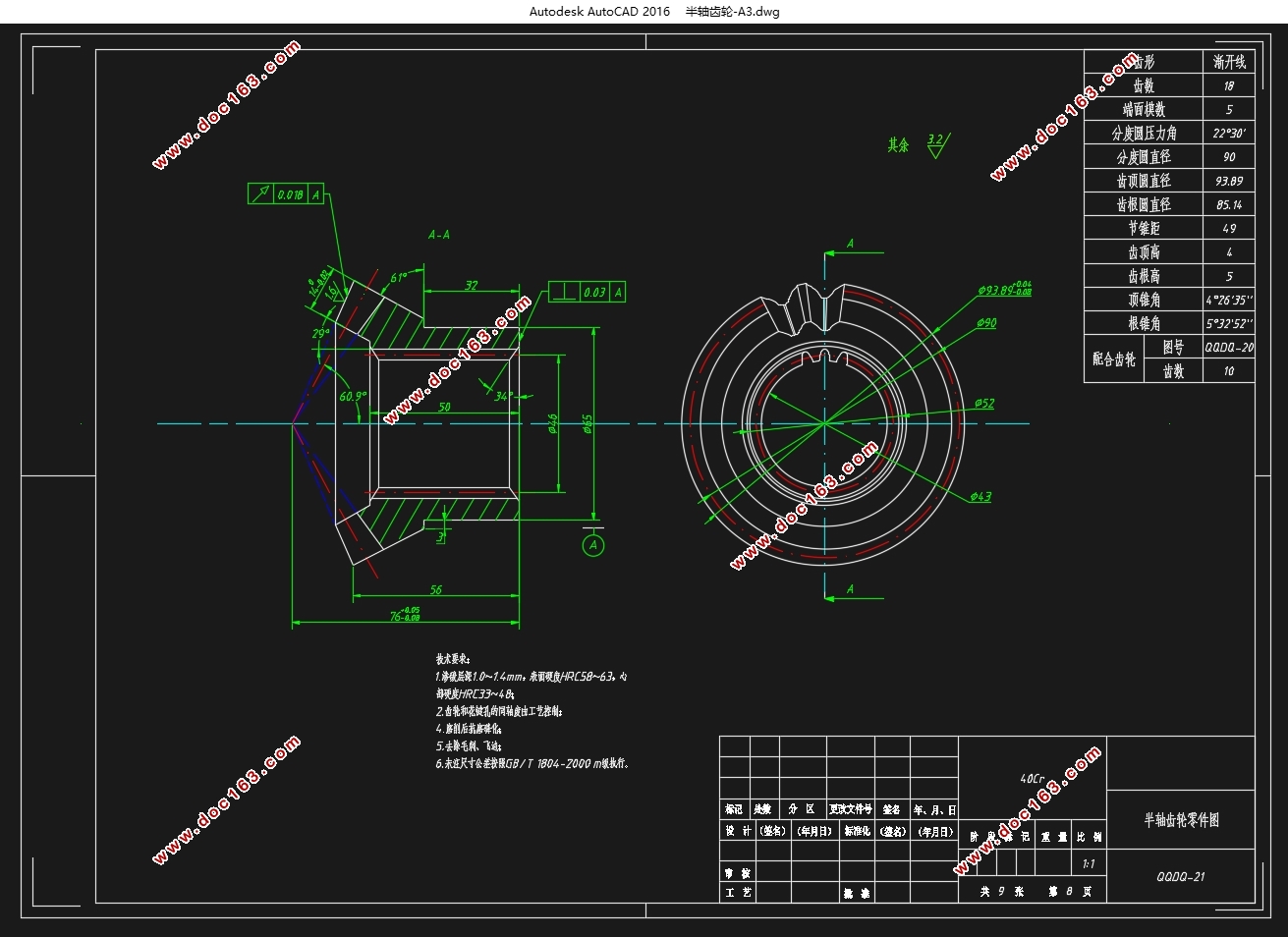

4.2.1 差速器齿轮基本参数的选择 18

4.2.2 差速器齿轮几何尺寸计算及强度校核 20

第5章 驱动车轮传动装置设计 24 [资料来源:www.doc163.com]

5.1 半轴型式的选择 24

5.2 半轴有关设计和计算 24

5.3 半轴结构和工艺设计 26

5.4 半轴的强度校核 26

第6章 驱动桥其余部件的设计 29

6.1 万向节的设计 29

6.2 分动装置的设计 30

6.3 驱动桥壳的设计 32

第7章 结论 34

参考文献 35

附录A 36

致 谢 40

上一篇:某7座中型SUV万向传动装置设计(含CAD零件图装配图)

下一篇:汉兰达7座中型SUV转向系统设计(含CAD零件图装配图)