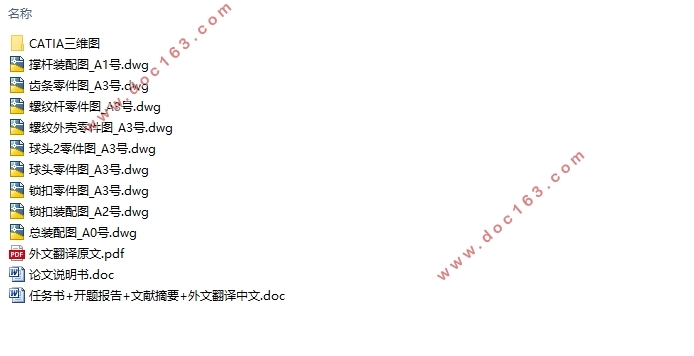

汽车电动尾门举升和锁扣机构设计(含CAD零件图装配图,CATIA三维图)

汽车电动尾门举升和锁扣机构设计(含CAD零件图装配图,CATIA三维图)(任务书,开题报告,文献摘要,外文翻译,论文说明书10000字,CAD图9张,CATIA三维图)

摘 要

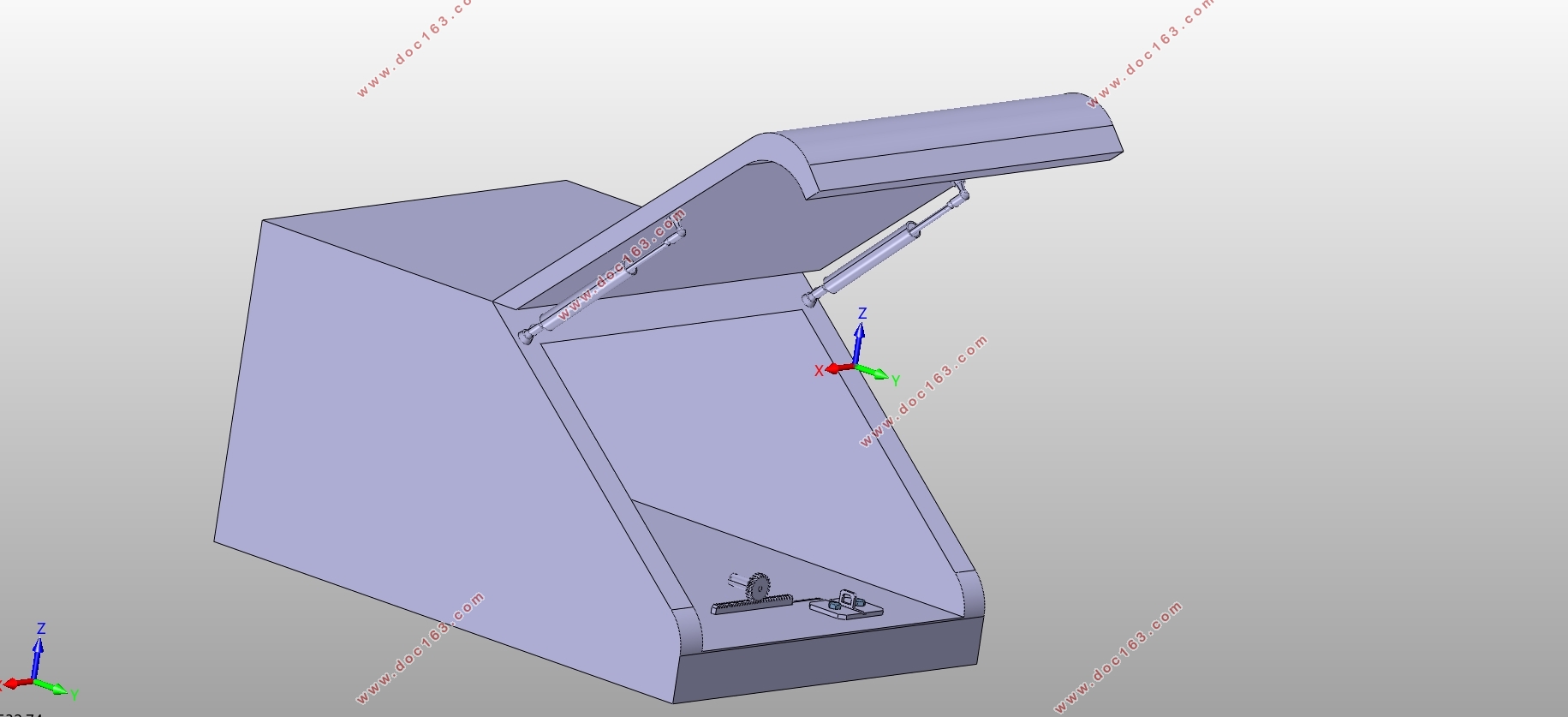

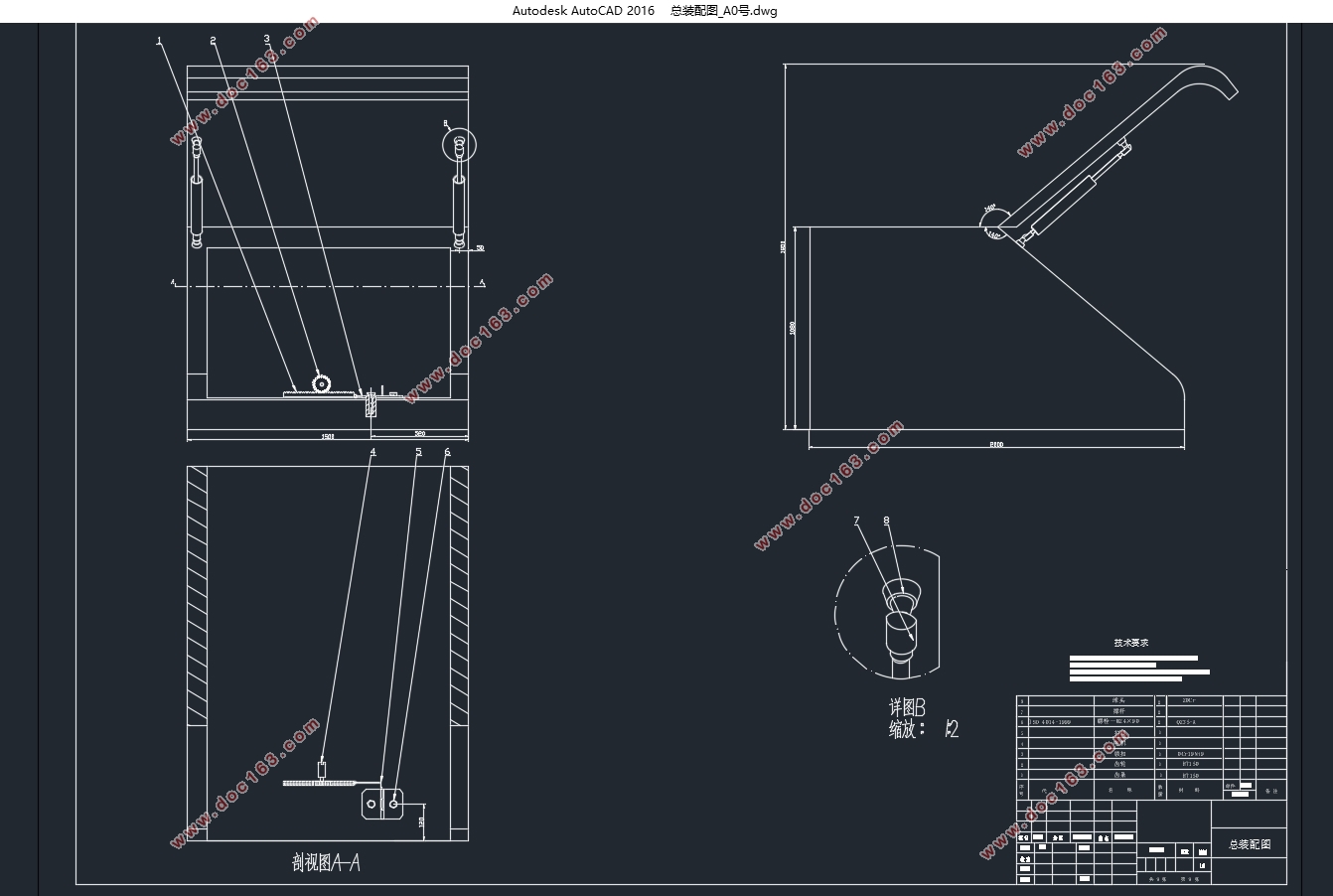

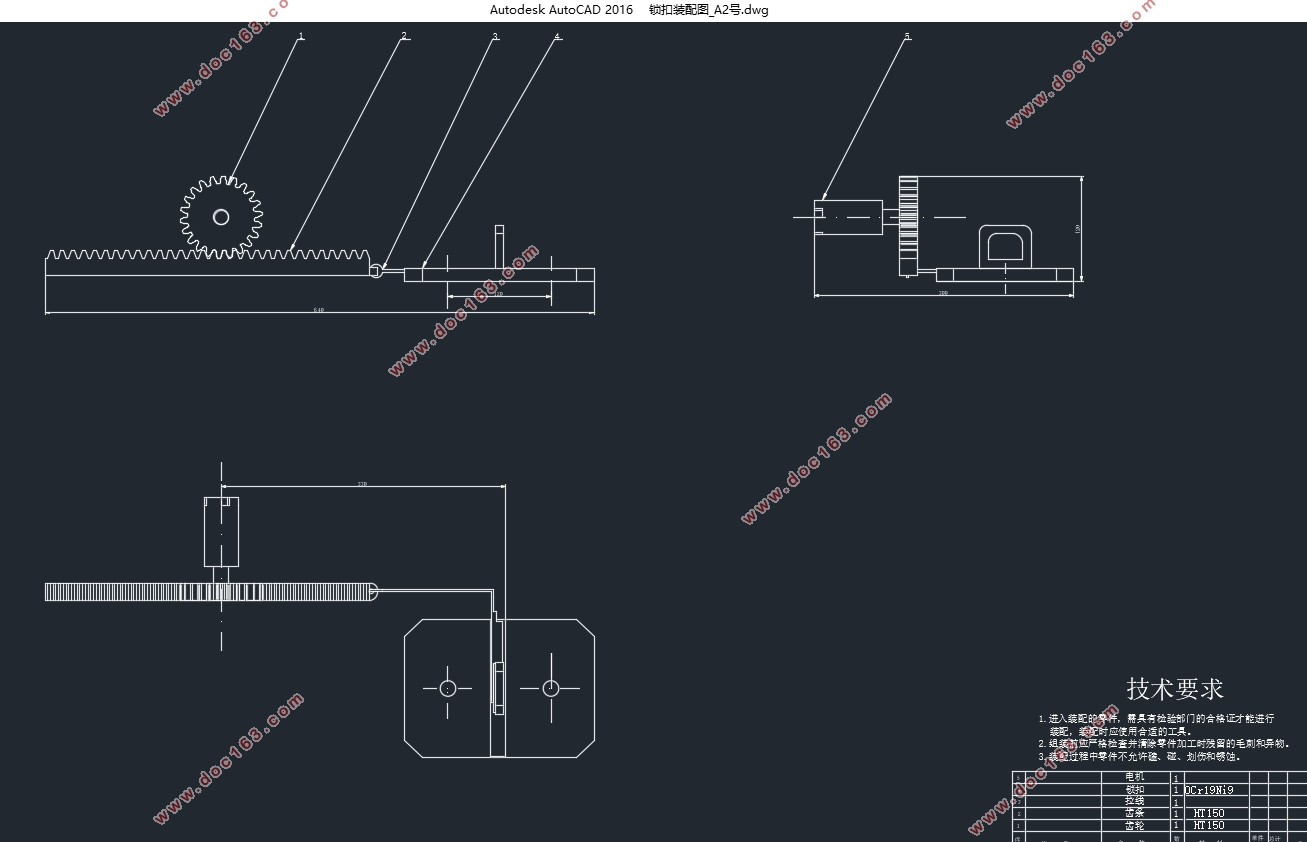

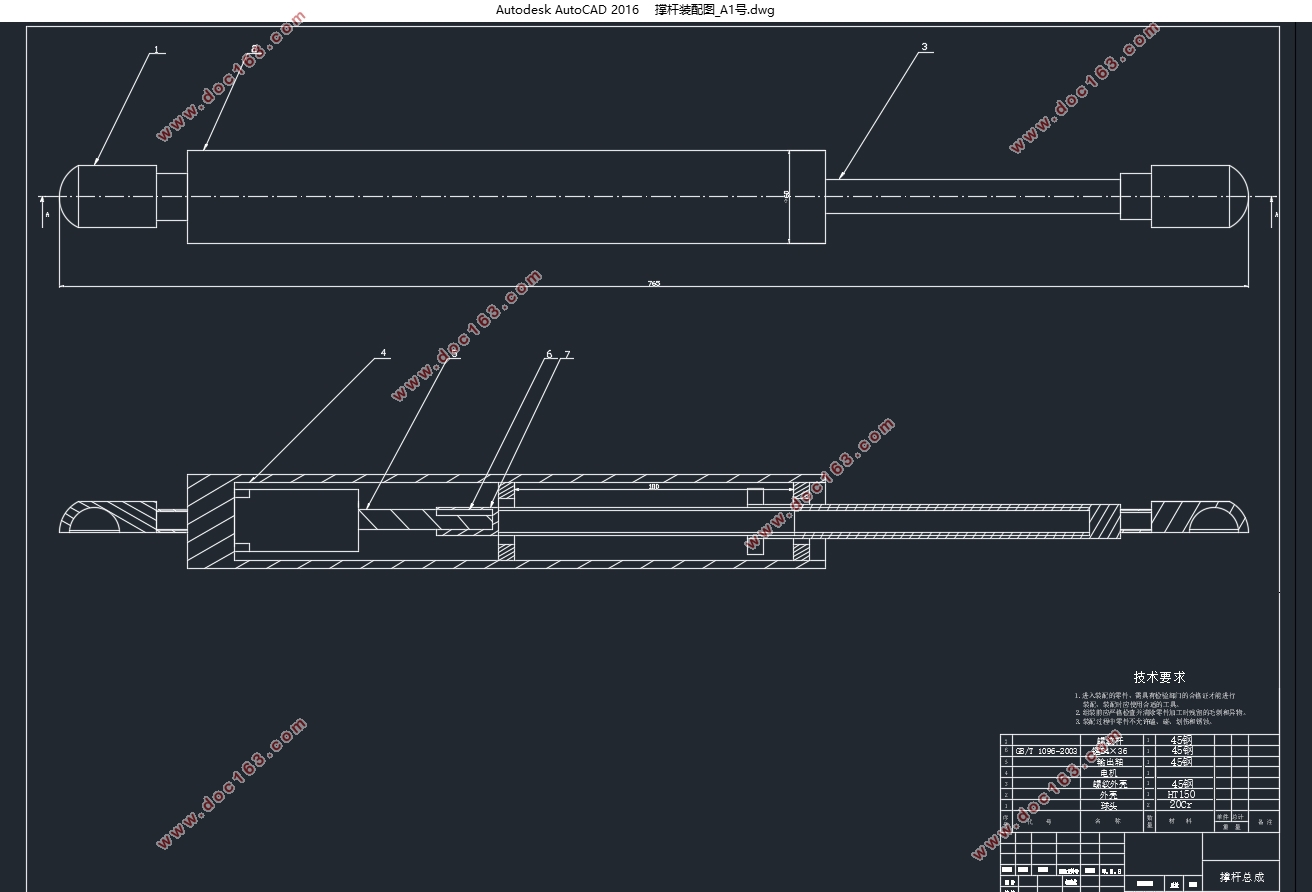

随着科技的发展,随着电子智能技术的发展,汽车产品生产与开发公司对汽车功能的智能化设计越来越重视。汽车开发过程中运用了越来越多的智能化技术,其中电动尾门技术逐步登上了汽车历史的大舞台,电动尾门的出现极大地改善了汽车的使用便利性。电动尾门具备很多普通尾门所不具有的功能,其中手自一体,智能防夹,紧急闭锁以及高度记忆功能是相对而言应用最多的。对尾门电动撑杆和电动锁扣进行研究,研制工作可靠性更高,结构合理、操作灵活的汽车电动尾门,从而增加电动尾门的附加值,有助于推动传统制造业产品升级换代的发展。此次是对电动尾门的举升机构和锁扣机构进行设计,建立电动尾门的举升机构和锁扣机构的总成三维模型并绘制二维图纸。

关键词:电动尾门;举升机构;锁扣机构

Abstract

With the development of technology and science and the development of electronic intelligence technology, automotive product production and development companies are paying more and more attention to the intelligent design of automotive functions. More and more intelligent technologies are used in the car development process, of which the electric tailgate technology has gradually entered the big stage of car history. The appearance of the electric tailgate has greatly improved the convenience of the car. The electric tailgate has a self-contained body that does not have an ordinary tailgate, smart anti-clamping, emergency lockout and high memory function. Research on rear door electric struts and electric locks, development of car electric tailgates with higher working reliability, reasonable structure and flexible operation, thereby increasing the added value of electric tailgates and helping to upgrade traditional manufacturing products development of. The design of the lift mechanism and locking mechanism of the electric tailgate was performed this time. The three-dimensional model of the lift mechanism and locking mechanism of the electric tailgate was established and a two-dimensional drawing was drawn. [资料来源:www.doc163.com]

Key Words:electric tailgate;Lifting mechanism;Locking mechanism

[资料来源:https://www.doc163.com]

[资料来源:https://www.doc163.com]

目 录

摘 要 I

Abstract II

第1章 绪论 1

1.1 研究背景与意义 1

1.2 国内外研究现状 2

1.3 研究内容与研究方法 2 [资料来源:https://www.doc163.com]

1.3.1 研究内容 2

1.3.2 研究方法 3

第2章 总体方案设计 4

2.1 汽车电动尾门整体构造 4

2.1.1 汽车电动尾门结构简介 4

2.2举升机构方案设计 4

2.2.1 传动机构方案设计 5

2.2.2 尾门开启时受力分析 5

2.2.3 电机选择 6

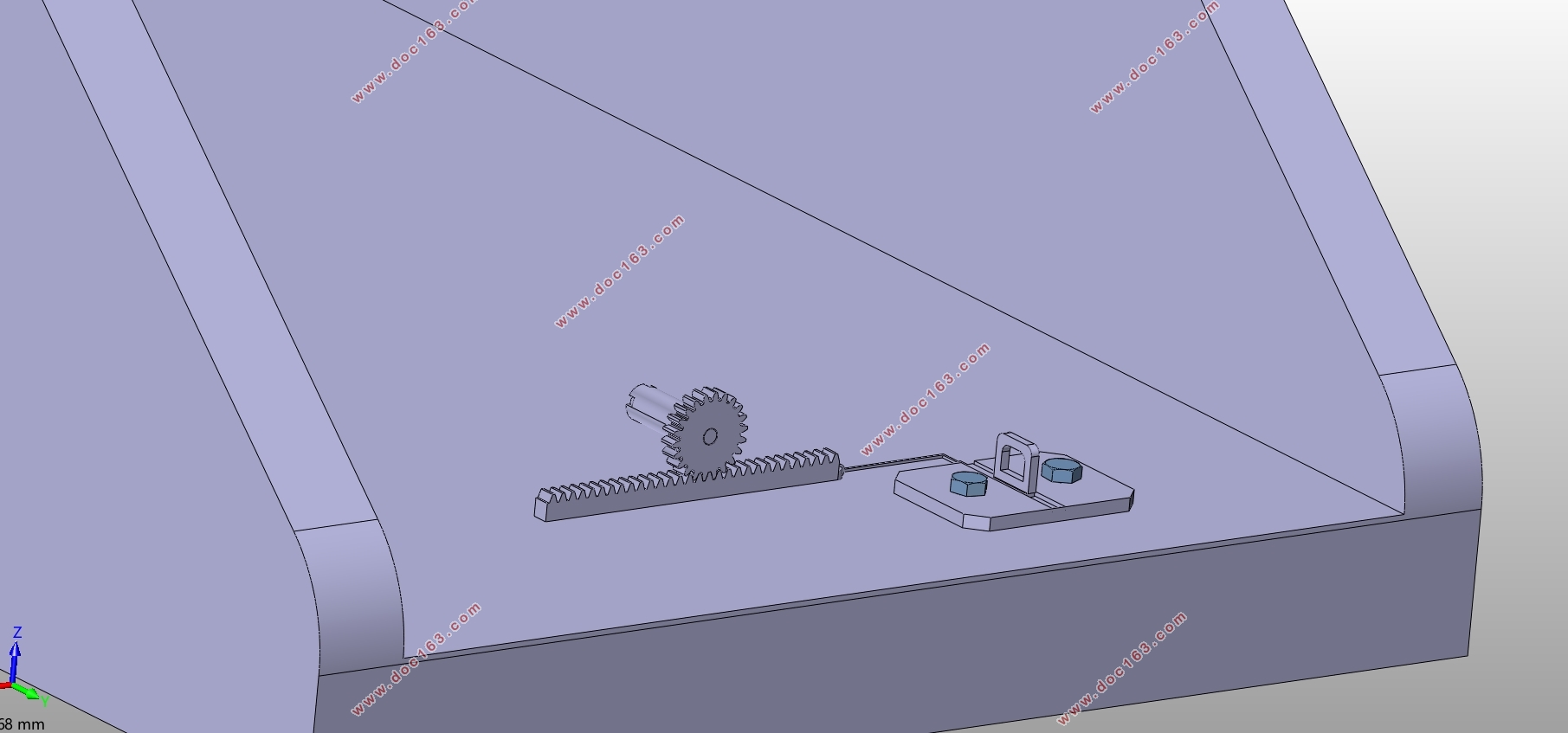

2.3 锁扣机构方案设计 7

2.3.1 锁扣的运动行程 7

2.3.2 传动机构的方案设计 7

2.3.3 拉线的设计 8

第3章 尺寸计算及强度校核 10

3.1 电撑杆的安装位置 10

3.2 电撑杆尺寸设计 11

3.3 电撑杆强度校核 11

3.4撑杆运动空间校核 13

3.5锁扣尺寸设计 13

第5章 总结 16

5.1 研究总结 16

5.2 研究展望 16 [资料来源:http://www.doc163.com]

参考文献 17

致谢 18

[资料来源:http://doc163.com]

上一篇:2100T柴油配气机构设计与仿真(含CAD零件图装配图,CATIA三维图)

下一篇:电动工程车总布置虚拟设计(含CAD零件图装配图,CATIA三维图)