小型柴油机活塞设计与强度分析(含CAD零件图装配图)

小型柴油机活塞设计与强度分析(含CAD零件图装配图)(论文说明书11000字,CAD图6张)

摘要

本设计重点介绍了小型柴油机活塞的具体设计思路。活塞组作为发动机零部件中一种技术含量较高的组件,在恶劣的工作条件下,往往会因为受到巨大的机械载荷和较高的热应力而使得活塞产生许多不利于活塞正常工作的形变,甚至会是活塞受到破坏而报废使得活塞的寿命下降,进一步的影响发动机的维修周期与寿命。这些不利于活塞的形变往往会造成活塞销座的开裂甚至断裂,环槽与活塞环的磨损,活塞裙部与气缸壁剧烈摩擦而导致烧伤甚至拉花[1]。随着科技的不断发展,活塞的设计方法也出现了越来越先进的方案、实验和工艺手段。CAD/CAE技术的发展使得活塞设计有了更加便捷的改进方案,CATIA软件能够直观的从各个角度观察分析设计的零件的形状特征,然后利用ANSYS软件进行有限元分析能够掌握活塞的机械载荷和热应力的分布,通过分析计算能够为活塞的设计提供更精确的改进方案。有限元的温度场设计能够很精确的模拟活塞工作是的实际环境温度,活塞在机械载荷下的受力变形情况能够在软件中直观的模拟出来,设计者可以通过对应力集中情况的分析来改进设计结构。

关键词:柴油机活塞强度

[资料来源:http://Doc163.com]

Abstract

This article mainly introduces the design of small diesel engine piston. As a kind of component with high technical content in engine parts, the piston group is often caused by the huge mechanical load and high thermal stress in the bad working conditions, which causes the piston to produce a lot of deformations which are not conducive to the normal work of the piston, and even the piston is destroyed and the piston's life is reduced. This will further affect the maintenance cycle and life of the engine. The deformations of the piston often cause the crack or even fracture of the piston pin, the wear of the ring groove and the piston ring, the severe friction between the piston skirt and the cylinder wall, which cause the burn and even the drawing. With the continuous development of science and technology, more and more advanced schemes, experiments and technological means have been developed for piston design. The development of CAD/CAE technology makes the piston design more convenient. The CATIA software can intuitively observe and analyze the shape characteristics of the parts designed and analyzed from various angles. Then the finite element analysis of the piston can be used to grasp the distribution of the mechanical and thermal stress of the piston by the ANSYS software, and can be used to calculate the piston by analysis and calculation. The design provides more accurate improvements. The temperature field design of the finite element can accurately simulate the actual ambient temperature of the piston work. The force deformation of the piston under the mechanical load can be intuitively simulated in the software. The designer can improve the design structure by the analysis of the stress concentration. [来源:http://www.doc163.com]

Key words: diesel engine,piston,strength

2.3活塞的设计参数

(1) 型号 CY6102BZQ

(2) 缸径102 mm

(3) 冲程118 mm

(4) 压缩比 16.5

(5) 工作容积 5.785 L

(6) 额定转速 2800 rpm

(7) 燃烧室形式ω型

(8)最大爆发压力15MPa

[资料来源:Doc163.com]

目录

摘要 1

Abstract 2

第一章 绪 论 1

1.1课题背景 1

1.2活塞的发展趋势 1

1.3活塞组设计与工艺的发展现状 2

1.3.1活塞部分 2 [资料来源:https://www.doc163.com]

1.3.3 活塞销 3

1.4 本文研究对象及主要内容 3

1.5 经济性分析 4

第二章 活塞组 5

2.1概述 5

2.2活塞组设计要求 5

2.2.1 活塞的机械负荷 5

2.2.2 活塞的热负荷 6

2.2.3 润滑不良 6

2.3活塞的设计参数 6

2.4活塞材料选择 6

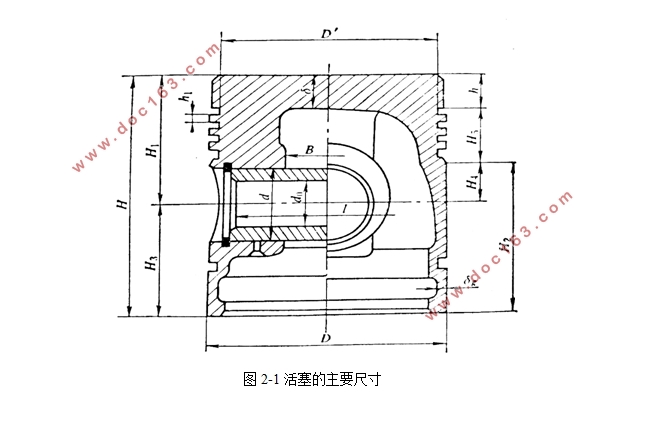

2.5活塞的主要尺寸确定 7

2.6活塞头部设计 9

2.6.1活塞顶 9

2.6.2活塞环槽 10

2.7活塞销座设计 11

2.7.1典型的销座结构 11

2.8活塞裙部及其侧表面形状设计 14

2.9 活塞环设计 16

2.10 活塞销设计 16

第三章 活塞的强度校核 18

3.1活塞顶的机械应力 18 [资料来源:http://Doc163.com]

3.2对第一环岸进行校核 18

3.3裙部比压 18

3.4活塞销座比压 : 19

第四章 三维实体模型的建立 20

4.2 ANSYS软件简介 21

4.3 活塞三维实体模型的建立 22

4.4 活塞的有限元分析 27

第五章 总结 30

参考文献 31

致谢 33

上一篇:某轻型越野车循环球转向器设计(含CAD图,CATIA三维图)