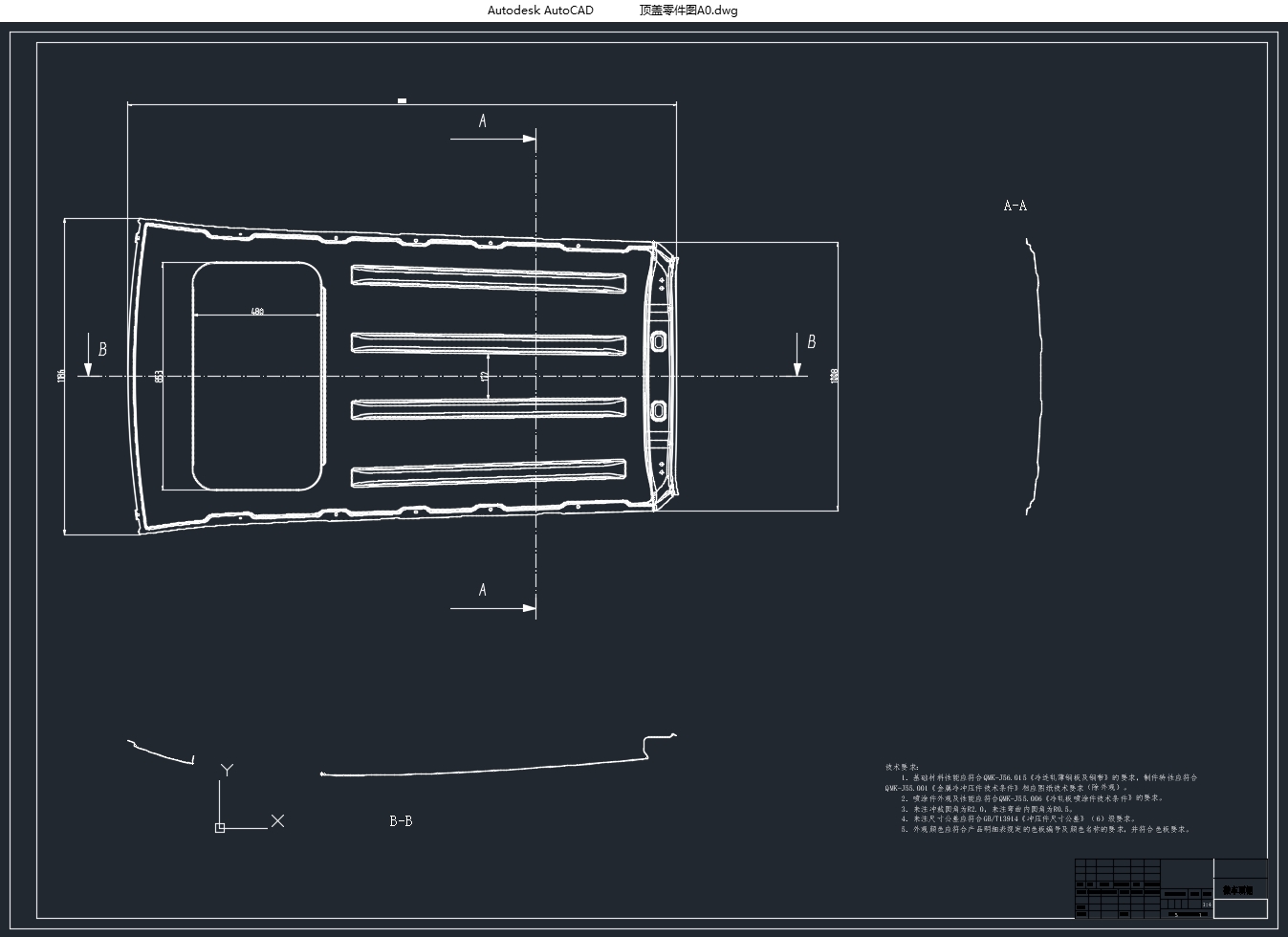

微车顶棚点焊超声自动化无损检测工艺与系统设计

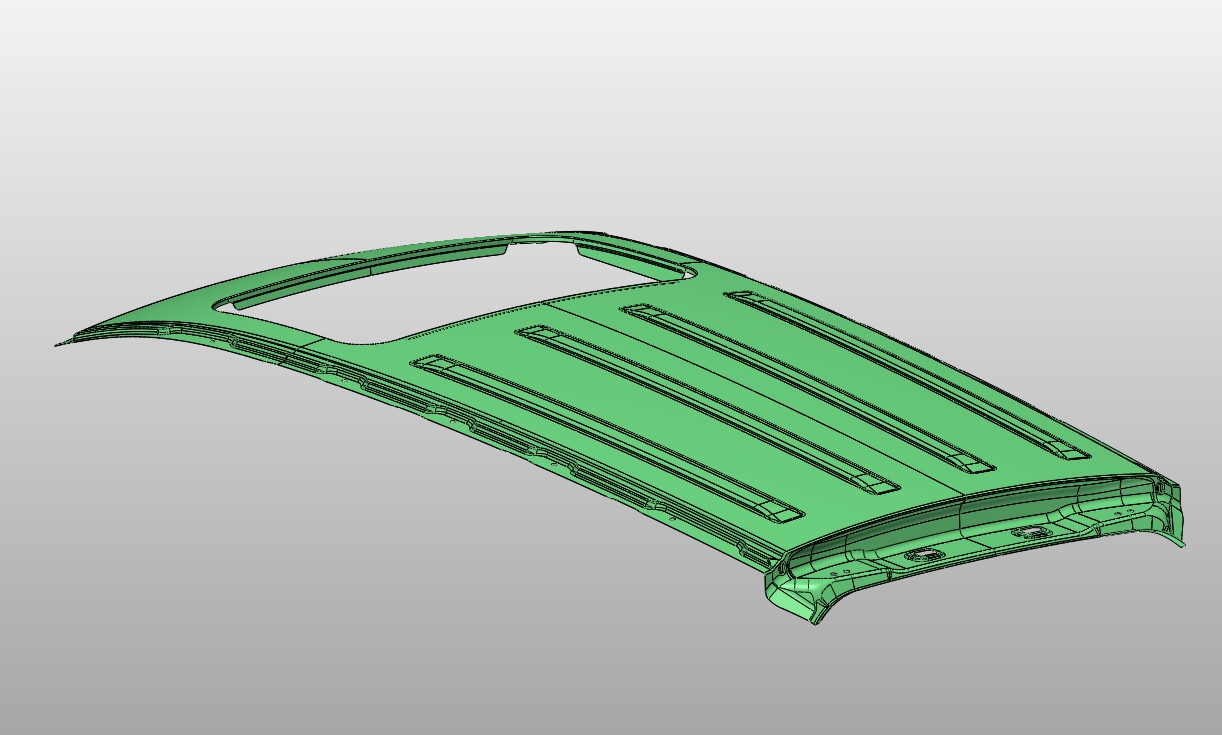

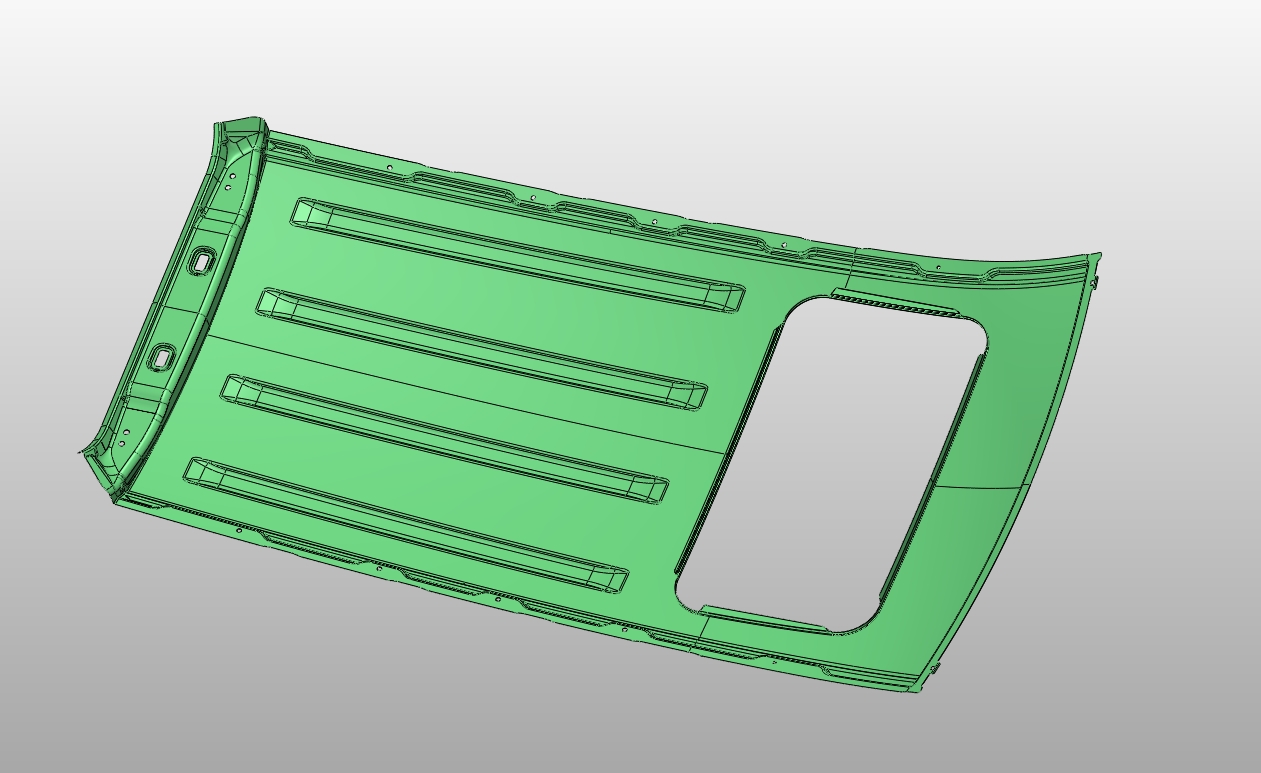

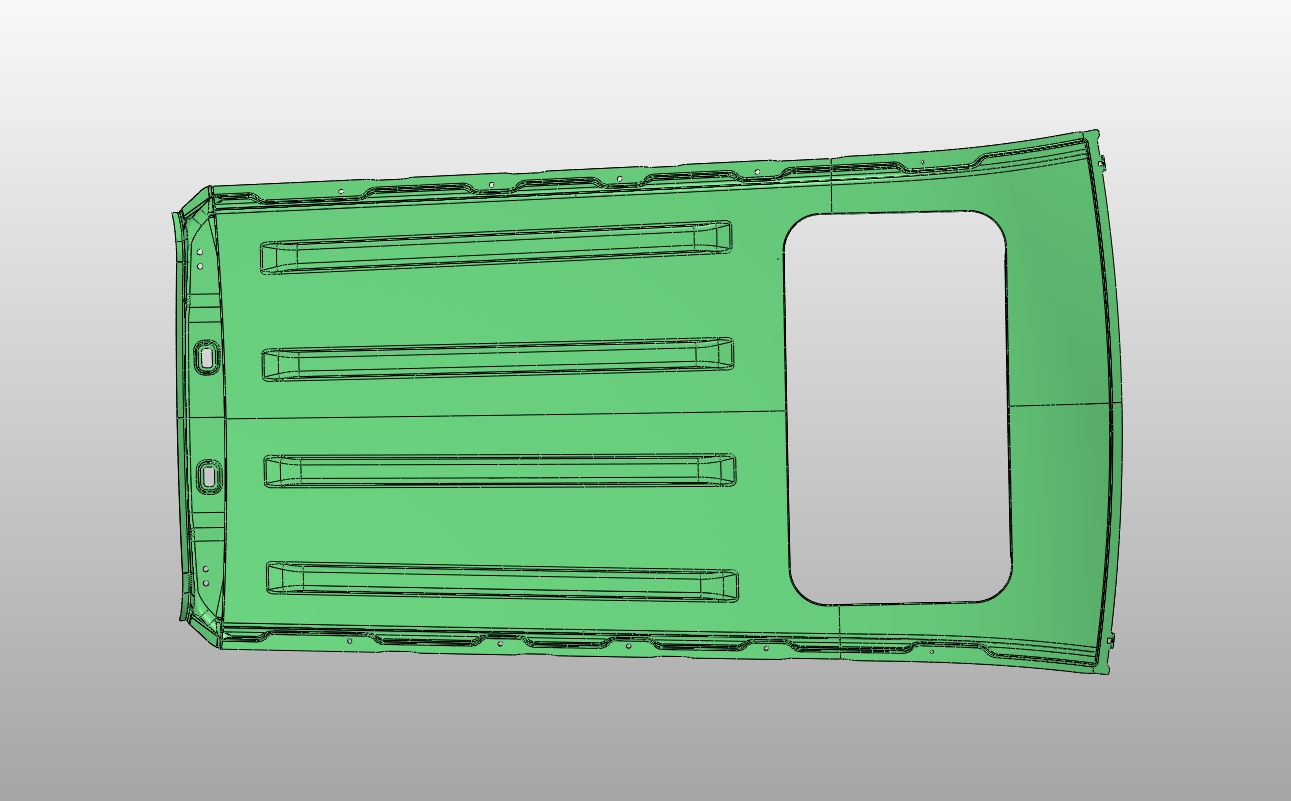

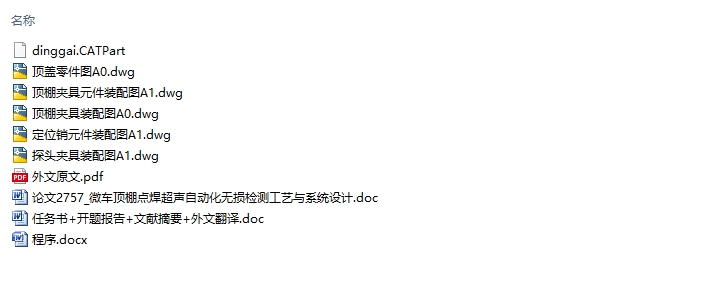

微车顶棚点焊超声自动化无损检测工艺与系统设计(含CAD图,CATIA三维图)(任务书,开题报告,外文翻译,论文说明书10000字,CAD图5张,CATIA三维图)

摘 要

随着工业化发展进程的推进,汽车在现代社会中的普及程度越来越高,汽车已经成为了人们生活出行重要的一部分,因此,汽车的安全性则成为了人们最为关注的重点。在汽车车体及车身的制造过程中,运用了多种连接方法,其中,焊接是应用最为广泛的。同时,点焊又是焊接方法中最常用的方法,从一个零件到整个白车身都有运用,每辆汽车的车体点焊焊点数量可达数千个,由此可以发现,点焊焊点的质量会影响到汽车车体的安全性,同时也会影响整车的可靠性。为了保证汽车的安全性和可靠性,焊点质量的检测是必不可少的,传统的检测是抽查检查,检测方法有目测、凿检、撕裂等,这种检测方法的可靠性和效率都有待提高。本文通过结合超声波无损检测技术以及工业机器人技术,研究了超声波无损检测的原理、回波特点及传感器技术,研究了工业机器人的编程及操作技术,并设计了点焊焊点的自动化检测系统,实现了点焊焊点的自动化无损检测,提高了检测效率和精度,对提高汽车的质量和可靠性有重要意义。

[资料来源:http://www.doc163.com]

关键词:超声无损检测;点焊质量;自动化;汽车

Abstract

With the advance of industrial developing process, the popularization rate of cars in modern society is becoming higher, and cars are playing an important role in

people's life. Thus, the security of cars has become the highlight to which people pay close attention. In the manufactory process of car body, people has adopted many

linking methods, among which the welding is most popular. Meanwhile, point

welding is most commonly used, and it has been used from an component to the

whole car body work. the point welding number of each car could reach several

thousands. Thus, the quality of welding spot has great influence on the security and

liability of car body. In order to enhance the security and liability of car, the detection of welding spots' quality could never be neglected, and the traditional detection is

sampling quality supervision, and those detection methods include visual test, inspection, splitting, and so on. However, the liability and efficiency of such methods

[资料来源:Doc163.com]

needs to be improved. By combining both ultrasonic non-destructive testing and

industrial robot, this thesis explores the principles of ultrasonic non-destructive testing, echo characteristics and sensors technology, and also studies the programming and

operating technique of industrial robot. Meanwhile, this thesis designs the automate

detecting system of welding spots, thus achieves the automate non-destructive testing of welding spots and improves the efficiency and accuracy of testing, which has great importance for improving the quality and liability of cars.

Key Word:ultrasonic non-destructive testing; quality of resistance spot weld; automation; automobile

[资料来源:www.doc163.com]

[版权所有:http://DOC163.com]

[版权所有:http://DOC163.com]

目 录

第1章 绪论 1

1.1 研究目的及意义 1

1.2 研究背景 1

1.3研究内容及目标 2

第2章 零件的检测工艺分析 4

2.1 电阻点焊的特点 4

2.2 超声无损检测原理 5

2.2.1超声波无损检测方法的分类 5

2.3 不同焊点的超声A扫描 6

2.4 夹具设计 7

2.4.1 Catia及AutoCAD的介绍 7

[来源:http://www.doc163.com]

2.4.2 超声波检测探头与机器人机械臂连接的夹具设计 8

2.4.3顶棚夹具的设计 9

2.5 检测路径的规划 10

2.6 超声波检测探头耦合剂供给系统的设计 10

第3章 机器人自动化检测程序开发 11

3.1 工业机器人技术介绍 11

3.2 RobotStudio软件介绍 11

3.3 动作路径程序的编写 11

第4章 超声波无损检测试验 16

4.1 设置超声波检测仪器相关参数 16

4.2 所制作试件的超声波检测实验 17

第5章 总结 19

参考文献 20

致 谢 21 [资料来源:http://www.doc163.com]

上一篇:汽车轴承轧制过程形状视觉测量系统设计(含CAD图,CATIA三维图)

下一篇:汽车起重机防摇动力学分析与控制系统研究(含CAD图,PLC程序)