重载车传动轴设计及有限元分析(含CAD图)

重载车传动轴设计及有限元分析(含CAD图)(任务书,开题报告,论文说明书10000字,CAD图3张)

摘 要

本文以某重载车传动轴为研究对象,在模型建立方面,将非重点平面处理为圆滑平整的面,避免了网格划分出错等问题,并运用有限元仿真的方法研究了传动轴的强度是否符合设计要求,对传动轴受力复杂的部位进行了深入分析,主要内容如下:

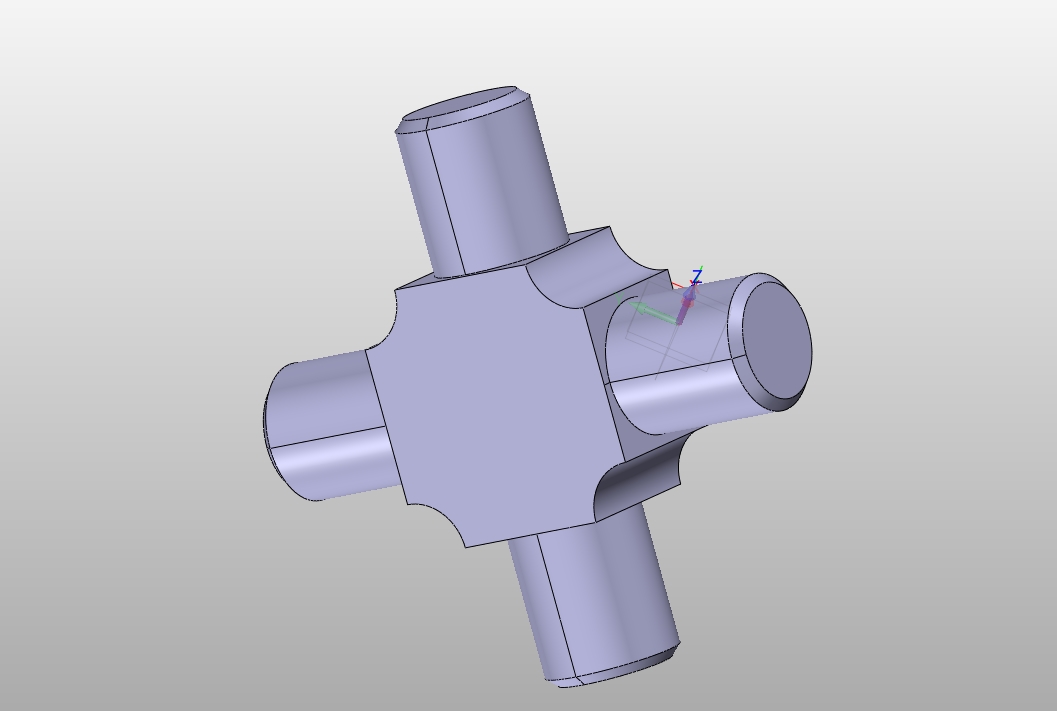

1)对该车型所匹配的传动轴进行三维建模,将轴身进行了合理的简化,将传动轴的受力最复杂的万向节部位进行了保留,建立了相对完善的三维模型。

2)对传动轴的组成部件分别定义材料,避免了由于选材而造成的设计强度不足等问题。

3)对设计好的传动轴模型进行有限元仿真并对传动轴中两大重要部件进行强度校核,主要包括万向节和传动轴轴身。将有限元分析的结果同传统的理论计算许用值进行强度校核,这样的设计过程,省略了在尺寸设计时的复杂计算,用有限元仿真的过程代替了传统的计算,大大的节约了设计用时。

研究结果表明:轴管断面最大弯曲应力为189MPa,小于300Mpa的许用应力,十字万向节的轴颈在承受最大的2000N•m扭矩时,最大弯曲应力为269MPa,小于350MPa的许用应力。在传动轴轴管材料和十字轴轴颈材料的屈服强度极限内,传动轴轴管和十字轴轴颈的应力、应变变化与承受扭矩的大小呈线性关系。 [版权所有:http://DOC163.com]

关键词:重载车;传动轴;有限元分析;强度校核;十字万向节

Abstract

In this paper, the transmission shaft of a heavy-haul vehicle is taken as the research object. In the aspect of model building, the non-key plane is treated as a smooth surface, which avoids the problems of meshing errors. The strength of the transmission shaft is studied by using finite element simulation method, and the complicated parts of the transmission shaft are analyzed in depth. The main contents are as follows:

1. The three-dimensional model of the transmission shaft matched by the vehicle is built, the axle body is reasonably simplified, the most complicated parts of the universal joint of the transmission shaft are retained, and a relatively perfect three-dimensional model is established.

2. Define the material of the components of the transmission shaft separately, which avoids the problem of insufficient design strength caused by material selection.

[来源:http://www.doc163.com]

3. Finite element simulation of the designed transmission shaft model and strength checking of the two important parts of the transmission shaft, mainly including universal joint and transmission shaft body. The result of finite element analysis is checked with the allowable value of traditional theoretical calculation. This design process omits the complex calculation in dimension design. The traditional calculation is replaced by the process of finite element simulation, which greatly saves the design time.

The maximum bending stress of axle tube section is 189 MPa, which is less than the allowable stress of 300 Mpa. The maximum bending stress of the Journal of the universal joint is 269 MPa, which is less than the allowable stress of 350 MPa when it bears the maximum 2000N m torque. Within the limit of yield strength of transmission shaft tube material and cross shaft journal material, the change of stress and strain of transmission shaft tube and cross shaft journal is linear with the magnitude of bearing torque.

[资料来源:http://www.doc163.com]

Key Words:Heavy Duty Vehicle;Drive Shaft;Finite Element Analysis;Strength Checking;Hooke JointwithAngle

[资料来源:http://Doc163.com]

[资料来源:Doc163.com]

目录

第1章 绪论 1

1.1论文的研究目的和意义 1

1.2国内外研究现状 1

1.3主要工作内容 3

第2章 传动轴模型建立及数据计算 4

2.1发动机型号选定 4

2.2变速箱型号选定 4

2.3十字轴工作原理 4

2.4 CATIA建立传动轴总成模型 5

2.4.1传动轴轴身设计 5

2.4.2十字轴设计 6

2.4.3滚针轴承设计 7

2.4.4中间支撑联接设计 8

2.4.5传动轴装配 9

2.5本章小结 9

第3章 传动轴的有限元分析 10

3.1有限元分析基本原理及步骤 10

3.1.1定义各部件材料 10

3.1.2划分网格、确定边界条件 11

3.1.3传动轴的应力、应变结果分析 13

3.2本章小结 16

第4章 传动轴的校核 17

4.1传动轴轴身强度校核 17

4.2十字万向节轴颈根部强度校核 18

4.3本章小结 19

第5章 总结与展望 20

5.1总结 20

5.2研究展望 20

参考文献 22

致谢 24

上一篇:汽车覆盖件500K型冲压机液压系统设计(含CAD图)

下一篇:燃料电池公交客车悬架设计(含CAD图,SolidWorks三维图)