数控铣床伺服系统设计(含电路图,连接图,程序,梯形图)

数控铣床伺服系统设计(含电路图,连接图,程序,梯形图)(含毕业论文21000字,答辩ppt,cad图纸13张)

摘 要

随着科学技术的发展,制造技术的进步,以及社会对产品质量和品种多样化的要求越来越强烈,要求现代数控机床成为一种精密、高效、复合、集成功能和低成本的自动化加工设备。同时,为满足制造业向更高层次发展,为柔性制造单元、柔性制造系统,以及计算机集成制造系统提供基础设备,也要求数控机床向更高水平发展。

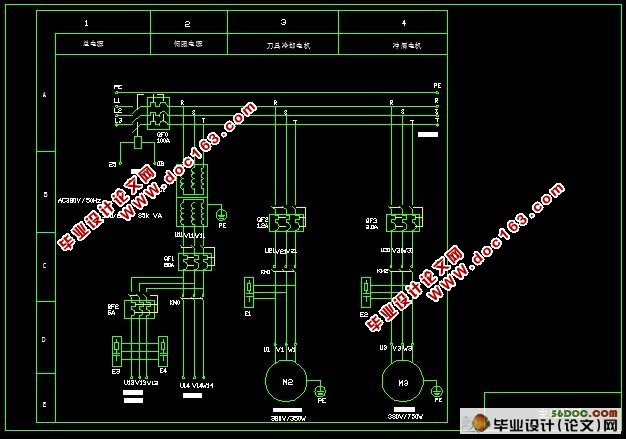

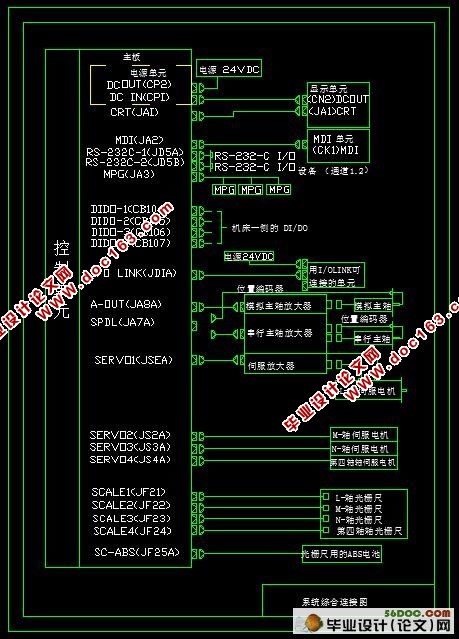

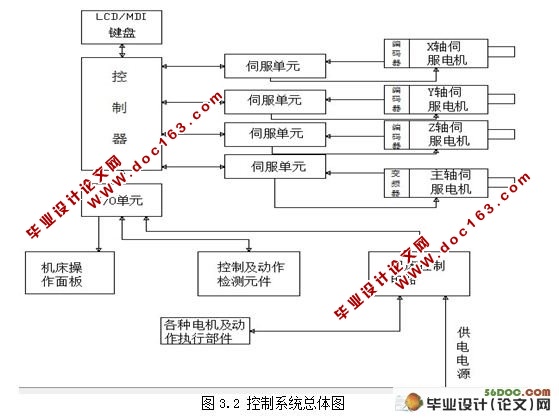

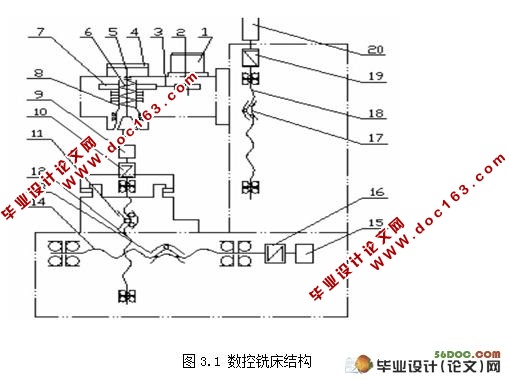

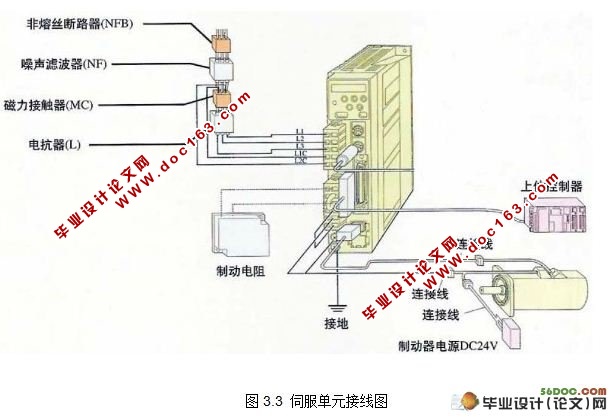

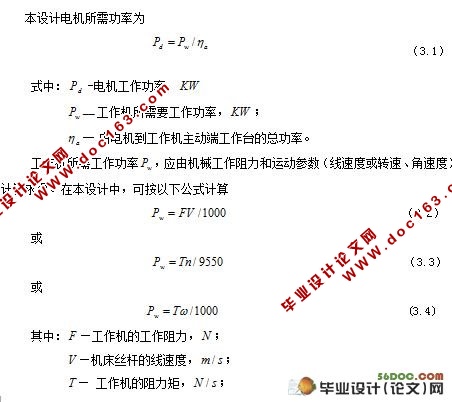

本文对数控铣床伺服系统进行设计,主要包括系统选型,信号连接,检测与控制,电气控制等。其中检测与控制主要是传感器的选用,电器控制主要是开关,灯的选用,还有内置PLC的编程以及仿真。本设计的出图包括主电路图,控制电路图,PLC控制图,信号连接图等。设计思路是总体设计,进给电机选择,检测系统设计,主电路设计,PLC设计,电磁兼容保护。

关键字:数控铣床伺服系统;电气控制;PLC设计

The design of servo system for CNC milling machine

Abstract

With the development of science and technology, the improvement of manufacturing technology, as well as social on product quality and diverse variety of requirement more and more intense, the requirement of modern CNC machine tools to become a precision, high performance, composite, integrated function and low cost automatic processing equipment. At the same time, in order to satisfy the manufacturing industry to a higher level of development, as the flexible manufacturing unit, flexible manufacturing system, and computer integrated manufacturing system provides the basic equipment, also called CNC machine tool to develop to higher level.

[资料来源:Doc163.com]

In this paper, the servo system in CNC milling machine design, including the system selection, signal connection, detection and control, electric control. The detection and control is the choice of sensor, electric control is the main switch, lamp selection, have built-in PLC programming and simulation. The design of drawing consists of main circuit, control circuit, PLC control chart, and signal connection diagram. Design thinking is the overall design, the feed motor selection, test system design, the main circuit design, PLC design, and EMC protection.

Keywords: Servo system in CNC milling machine; Electrical control; the design of PLC

本设计的目的和内容

伺服系统是用来精确地跟随或复现某个过程的反馈控制系统。又称随动系统。在很多情况下,伺服系统专指被控制量(系统的输出量)是机械位移或位移速度、加速度的反馈控制系统,其作用是使输出的机械位移(或转角)准确地跟踪输入的位移(或转角)。伺服系统的结构组成和其他形式的反馈控制系统没有原则上的区别。

此次数控铣床伺服系统设计的选题能全面反映培养目标,与本专业密切相关,进一步巩固和加深所学的理论知识,能结合社会生产实际或科研实践,现实意义突出,具有一定的先进性,与市场的结合性好。通过本次数控铣床伺服系统设计,应使我在系统设计、绘图能力、查阅科技文献资料、使用各种标准、手册的基础上得到培养和锻炼。在综合训练过程中锻炼工程应用能力,启发创新能力,善于应用新技术、新工艺、新材料。 [资料来源:http://www.doc163.com]

[资料来源:http://Doc163.com]

[资料来源:http://Doc163.com]