汽车覆盖件消失模专用龙门式数控铣床的设计★

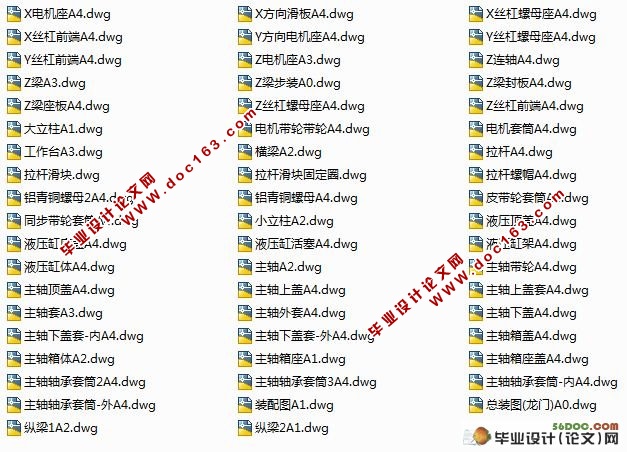

汽车覆盖件消失模专用龙门式数控铣床的设计★(开题报告,答辩ppt,论文说明书21000字,计算程序,cad图纸)

摘要

数控龙门铣床是现代加工大型工件的一种新型机床,它能使工件在一次装夹下,进行多工序加工,从而可提高生产率三至四倍,并能使工件获得很高的加工精度和表面质量。因此,其用途很广,是船舶、航天航空、模具、精密仪器等民用工业和军工部门追切需要的关键加工设备。

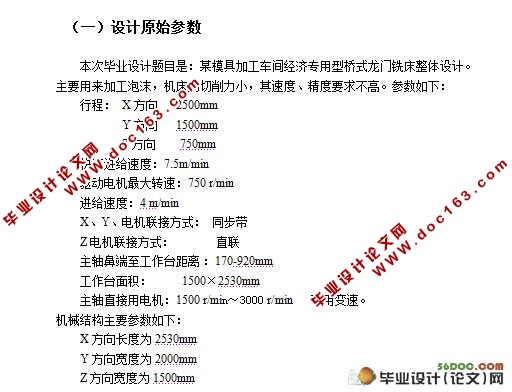

本课题以大型汽车覆盖件用的消失模加工铣床为研究对象,在对消失模专用桥式数控龙门铣床的特点进行分析的基础上,通过采用现代设计手段对该类铣床进行设计。从现有数控铣床的发展现状和成熟的理论基础出发,对模具加工机床的受力及振动变形进行分析,掌握机床的受力情况,为机身的优化提供基础数据。

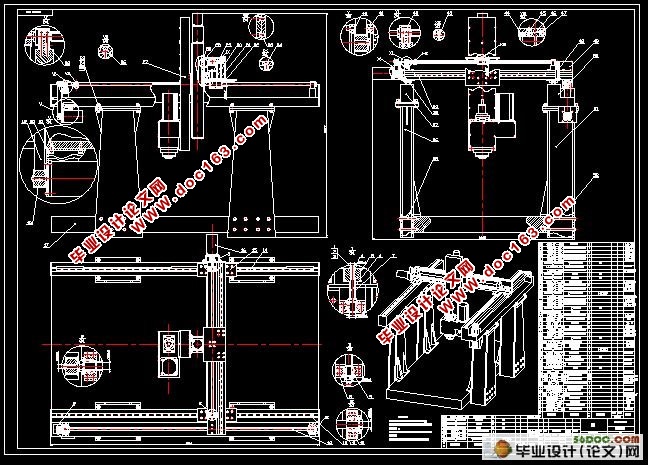

该数控龙门铣床利用MACH2软件建立通用数控平台;采用钢结构焊接立柱,通过单X轴驱动、L型横梁、同步带传动、龙门移动式结构、三轴联动等作为机床设计方案,这保证低成本又可以保证加工精度与加工速度的要求。

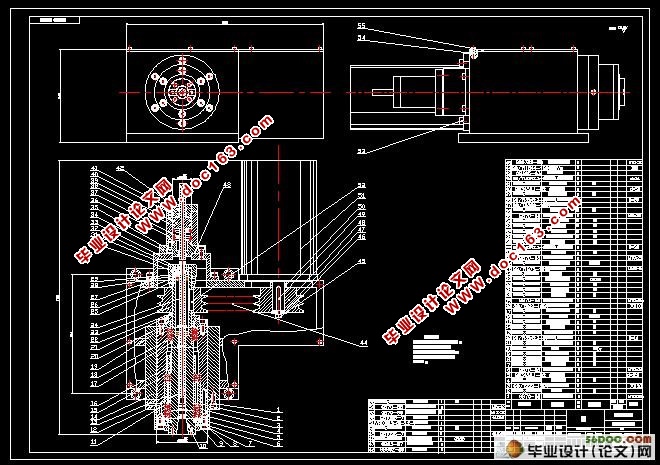

机械结构设计包括传动方案的确定与选择、滚动丝杠副选择、滚动导轨副的计算与选择、步进电机的选择、联轴器的选择等。机床拟采用MACH2作为数控系统平台,系统安装在计算机上,通过并口与步进电机驱动器连接,能实现在线加工加工的本机化功能。 [资料来源:https://www.doc163.com]

关键词 消失模 数控 桥式数控龙门铣床

Abstract

Gantry milling machine is a kind of modern machine and often used to machine large workpiece. It can machine workpiece by multi-process procedure under workpiece being in each set up, to boost productivity triplication to quadruple, can make workpiece with high machining accuracy and surface quality. So it has many uses in civilian industry and defense industry such as in ship building, spacecraft, mould, precision instrument etc. It is the key equipment which department needs urgently.

The object of study of the subject is the milling machine which used for machining the EPC of the large-scale automobile panel, basis on analysising the characteristics of the Gantry NC milling machine which used for machining the EPC, design the type of milling machine through using of the modern design means. Starting from the development status of the existing NC milling machine and the sophisticated theoretical foundation, have the mold processing machine tools analysised the force and the deformation vibration, Master the forces of the Machine, provide basic date for optimizing the fuselage.

[资料来源:http://www.doc163.com]

The gantry milling machine is used the Mach2 software to develop the common NC platform; used of steel welding pillar, driven by single-X-axis, L-beams, used synchronous transmission belt, gantry mobile structure, triaxial linkage as the design program. That is, can ensures low-cost, the processing precision and processing speed requirements.

The mechanical structure design, including decision and choice of the driving program, choice of screw rolling, calculation and choice of the rolling guide, the choice of step motor, choice of coupling, and so on. The machine tools is used a MACH2 as NC system platform, the system installed on your computer, through the parallel port connected the stepper motor drive, so as to achieve the local processing of On-line processing functions.

Keywords EPC NC Gantry NC milling machine

[资料来源:www.doc163.com]

机械系统

整机分为床身、龙门架、滑台、主轴箱、三轴进给驱动机构机械部分及相关数控伺服部分。支承件是机床的基础构件,如立柱、桥梁、滑座、横梁、拖板、滑枕及工作台等。机床的各种支承件中有的互相固定连接,有的则在导轨上作相对运动。在切削加工中,刀具与工件间相互作用的力沿着大部分支承件逐个传递并使之变形。支承件的变形将直接影响机床的加工精度,因此,它是机床十分重要的构件。

[资料来源:Doc163.com]

(1)支承件的基本设计要求如下:

①应具有足够的刚度。即支承件在规定的最大载荷作用下,变形不得超过一定的数值,以便保证刀具和工件间的相对位移不超过加工精度允差。

②应具有足够的抗振性。抗振性包括两方面的意义:一个是抵抗受迫振动的能力——限制受迫振动的振幅不超过允许值;另一个是抵抗自激振动的能力——在给定的切削条件下保证切削的稳定性。

③一般应具有较小的热变形和热应力。

④应该排屑畅通,吊运安全,并具有良好的工艺性以便于制造和装配。

(2)刚度是设计支承件应该满足的首要条件。提高支承件的刚度方法主要有以下几个:

①选择有利的截面形状

机床支承件受载荷的情况是复杂的,但不外乎拉、压、弯、扭四种情况及其组合。当支承件受弯曲和扭转载荷时,支承件的变形不但与截面面积大小有关,而且与截面形状,即与截面惯性矩有很大关系。表2为截面近似地皆为10000 的十种不同的截面形状的抗弯和抗扭惯性矩的比值。这个比值是以圆形截面惯性矩为对比基准,其他惯性矩与之相比荷得的数值。