基于UG的数控加工鼠标仿真

基于UG的数控加工鼠标仿真(任务书,开题报告,外文翻译,论文说明书10000字,UG实体图1张)

摘 要

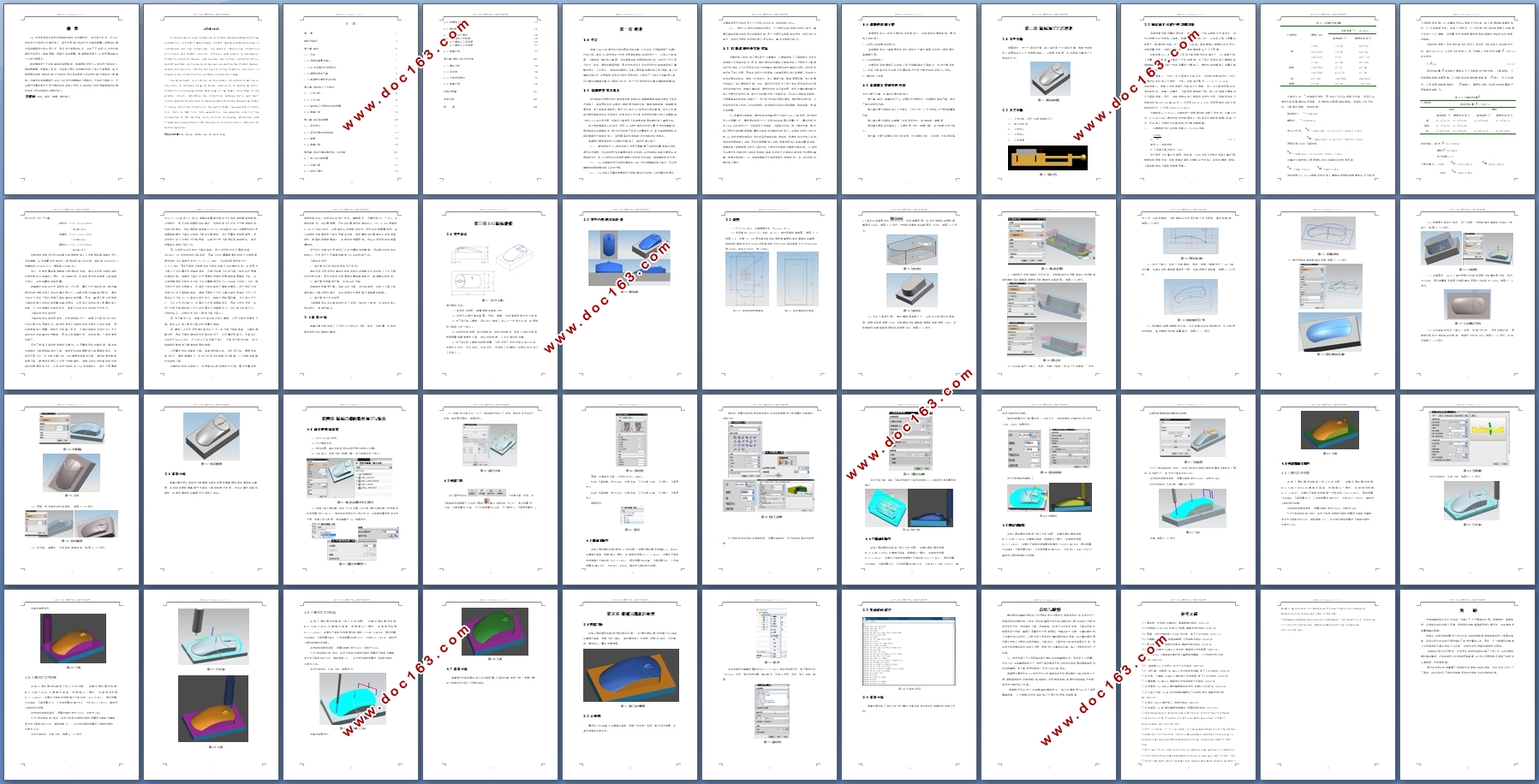

UG 技术是实现产品设计和制造自动化的关键技术,在产品开发中,引入该技术进行产品设计及数控加工,能大大提高产品的生产效率和质量。曲面在机械产品和模具设计中应用广泛,而且由于曲面的特点,决定了只有用UG技术才能缩短产品设计、制造周期、提高产品的质量。本课题就是基于UG软件围绕着这一应用主题展开。

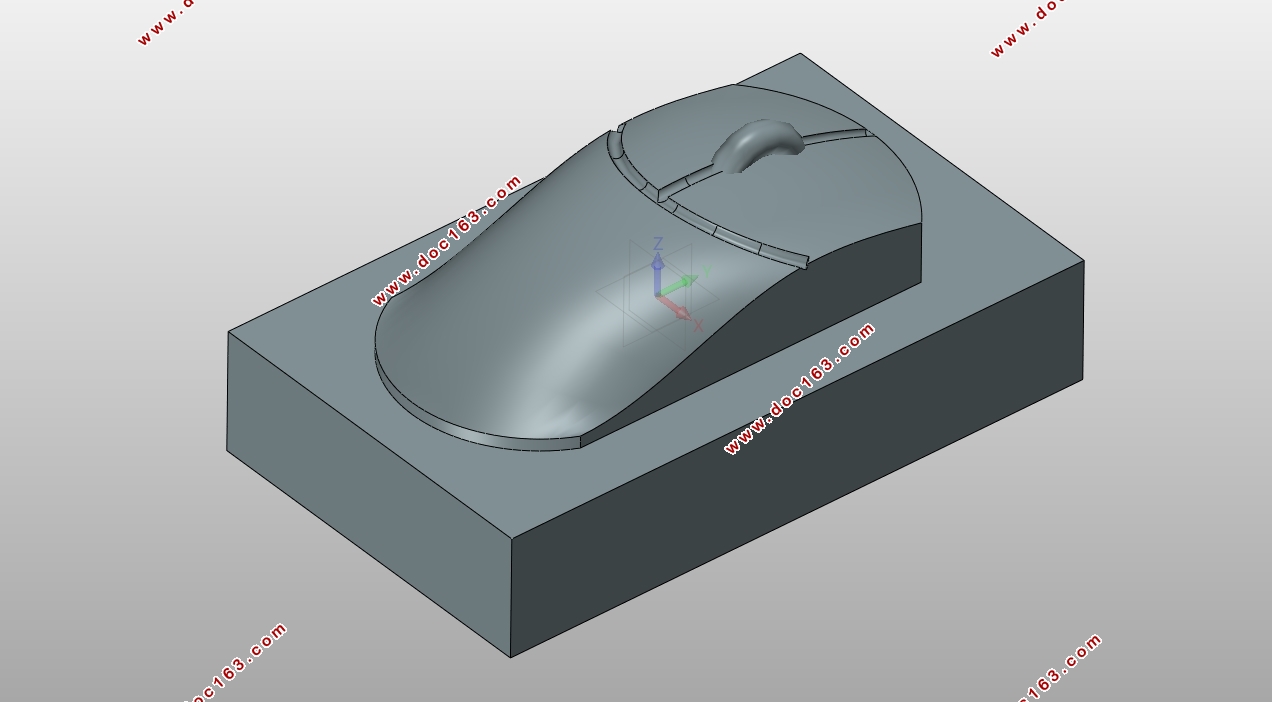

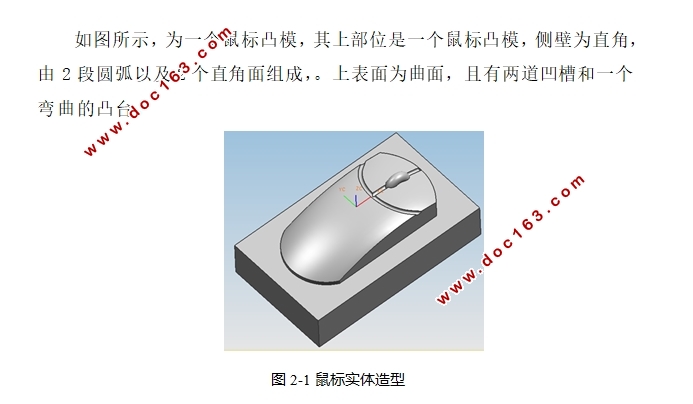

鼠标模型是一个比较典型的曲面模型,本课题就是用UG软件进行鼠标的三维曲面建模,仿真加工零件,生成加工程序并在数控机床上加工出其模型。首先根据图形实物,确定各部分之间的比例关系并参照自己的设计建出鼠标的三维模型。创建后的实体模型可以在CAM中生成精确的刀具路径。生成的刀具路径,可以通过后置处理产生用于数控机床的加工代码。生成的加工代码传输到指定的数控机床上来完成鼠标的数控加工。

关键词 :UG;鼠标;建模;数控加工

abstract

UG technology is a key technology in product design and manufacturing automation, in product development, product design and NC machining is introduced into the technology, can greatly improve the production efficiency and product quality. Surfaces used widely in mechanical products and mold design, and because the surface characteristics, determined that only using UG technology can shorten the product design, manufacturing cycle, improve the quality of the products. This topic is based on the UG application software around this theme.

The mouse model is a typical surface model, 3D surface modeling is the topic of software using UG mouse, simulation of machining parts, production processing and NC machining of the model. According to the graphic object, determine the proportion between parts and their relationship with reference to design and build a three-dimensional model of mouse. After the creation of the entity model can generate accurate tool path in CAM. Tool path generation, can generate code for the processing of CNC machine tools by post processing. Machining code transmission generated to CNC machine tools specified to complete CNC machining mouse

Keywords: UG;Mouse;Modeling;NC machining

[资料来源:http://www.doc163.com]

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

[资料来源:www.doc163.com]

1.1引言 1

1.2 选题的背景及意义 1

1.3 UG技术国内外发展状况 2

1.4课题的基础了解 3

1.5本课题主要研究的内容 3

第二章 鼠标加工工艺理论 4

2.1工件分析 4

2.2工艺分析 4

2.3确定加工过程中的切削用量 5

2.4本章小结 10

第三章 UG鼠标建模 11

3.1零件设计 11

3.2零件凸模的实体造型 12

3.3建模 13

3.4本章小结 20

第四章 鼠标凸模的数控加工与仿真 21

4.1加工的初始设置 21

4.2创建刀具 22

4.3粗加工操作 23

4.4半精加工操作 25

4.5固定轮廓铣 26

4.6创建精加工操作 28

4.6.1精加工外轮廓 28 [资料来源:http://www.doc163.com]

4.6.2精加工工件四周 30

4.6.3精加工工件曲面 32

4.7本章小结 33

第五章 模拟刀轨及后处理 34

5.1模拟刀轨 34

5.2后处理 34

5.3生成代码程序 36

5.4本章小结 36

总结与展望 37

参考文献 38

致 谢 40 [版权所有:http://DOC163.com]