汽车变速箱箱体加工工艺及夹具设计(附工艺过程卡)

汽车变速箱箱体加工工艺及夹具设计(附工艺过程卡)(含选题审批表,任务书,开题报告,中期检查表,工艺过程卡,论文说明书19000字,CAD图纸6张合一)

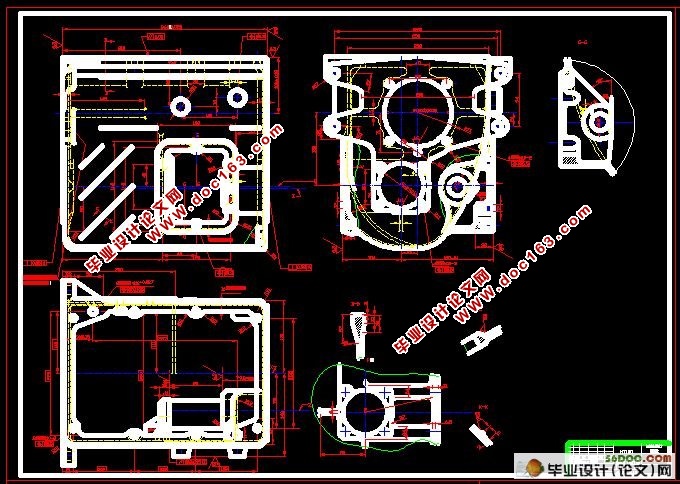

摘 要: 本设计是汽车变速箱箱体零件的加工工艺规程及一些工序的专用夹具设计。汽车变速箱箱体零件的主要加工表面是平面及孔系。因此,本设计遵循先面后孔的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔系加工精度。基准选择以变速箱箱体的输入轴和输出轴的支承孔作为粗基准,以顶面与两个工艺孔作为精基准。主要加工工序安排是先以支承孔系定位加工出顶平面,再以顶平面与支承孔系定位加工出工艺孔。在后续工序中除个别工序外均用顶平面和工艺孔定位加工其他孔系与平面。支承孔系的加工采用的是坐标法镗孔。

关键词:变速箱;加工工艺;专用夹具;基准

The Special-purpose Clamping Appararus of the Machining Technology Process and Some Working Procedures of the Car Gearbox Parts

Abstract: The design is about the special-purpose clamping apparatus of the machining technology process and some working procedures of the car gearbox parts. The main machining surface of the car gearbox parts is the plane and a series of hole. So the design follows the principle of plane first and hole second. And in order to guarantee the working accuracy of the series of hole, the machining of the hole and the plane is clearly divided into rough machining stage and finish machining stage. The supporting hole of the input bearing and output bearing is as the rough datum. And the top area and two technological holes are as the finish datum. The main process of machining technology is that first, the series of supporting hole fix and machine the top plane, and then the top plane and the series of supporting hole fix and machine technological hole.

Key words: gearbox; machining technology; special-purpose clamping apparatus; datum

[版权所有:http://DOC163.com]