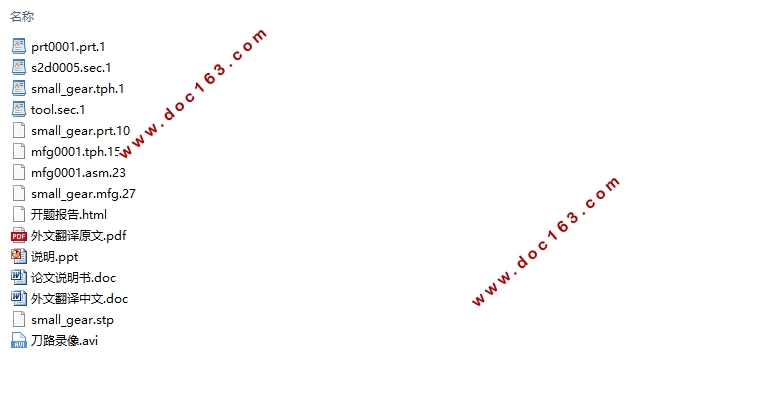

基于PRO/E的直齿轮铣削加工仿真(含Proe三维图)

基于PRO/E的直齿轮铣削加工仿真(含Proe三维图)(开题报告,外文翻译,论文计算书10000字,STP三维图,PRO/E三维图)

摘要

仿真加工的意义在于对设计制造过程的模拟与检查,可以在进行实际加工前运用软件模拟的方式来得到加工过程和结果。可以在没有损失的情况下对在实际加工过程中的各种负面情况如过切、刀具选择错误、进给路线错误、进退刀方式不合理、刀具与约束控制面干涉等进行有效的暴露,从而便于解决。同时仿真加工也可以更直观的表现出零件成型的过程,让生产人员对生产的零件与加工过程从感官上有直接的认识。

PRO/ENGINEER(PRO/E)是由美国参数技术公司(PTC)开发的CAD/CAM/CAE一体化的三维软件。PRO/E软件以参数化著称,是参数化技术的最早应用者,在目前的三维造型软件领域中占有着重要地位。PRO/E作为当今世界机械CAD/CAE/CAM领域的新标准而得到业界的认可和推广,是现今主流的CAD/CAM/CAE软件之一,特别是在国内产品设计领域占据重要位置。

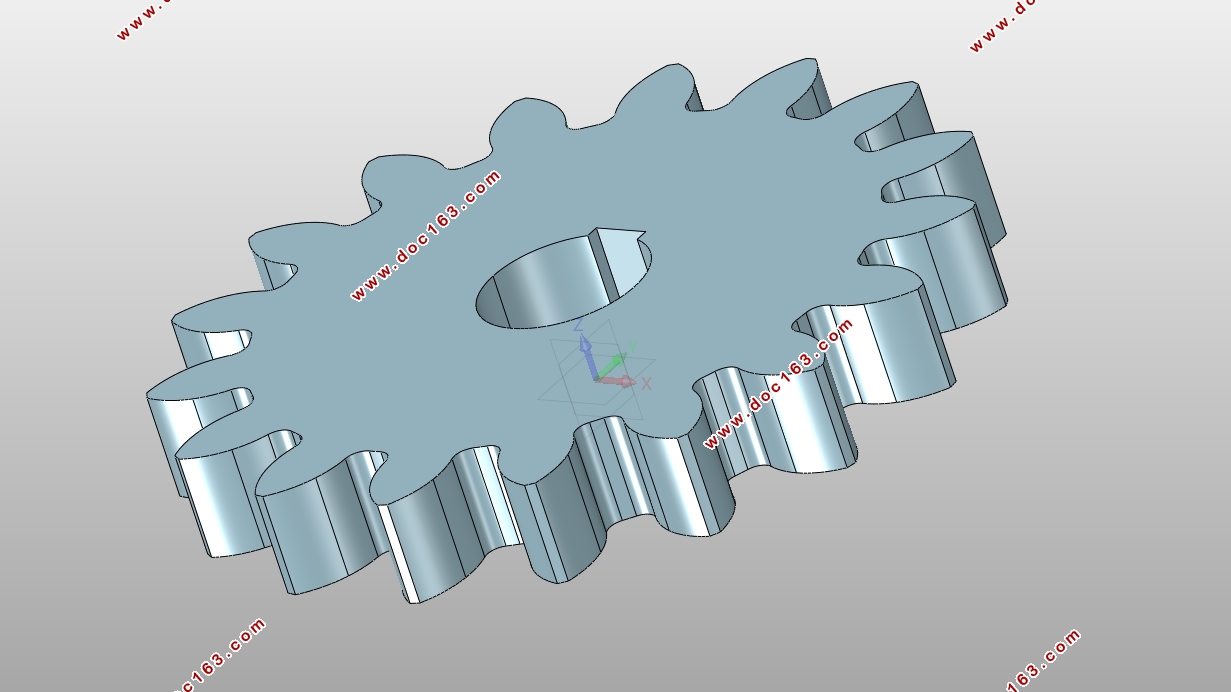

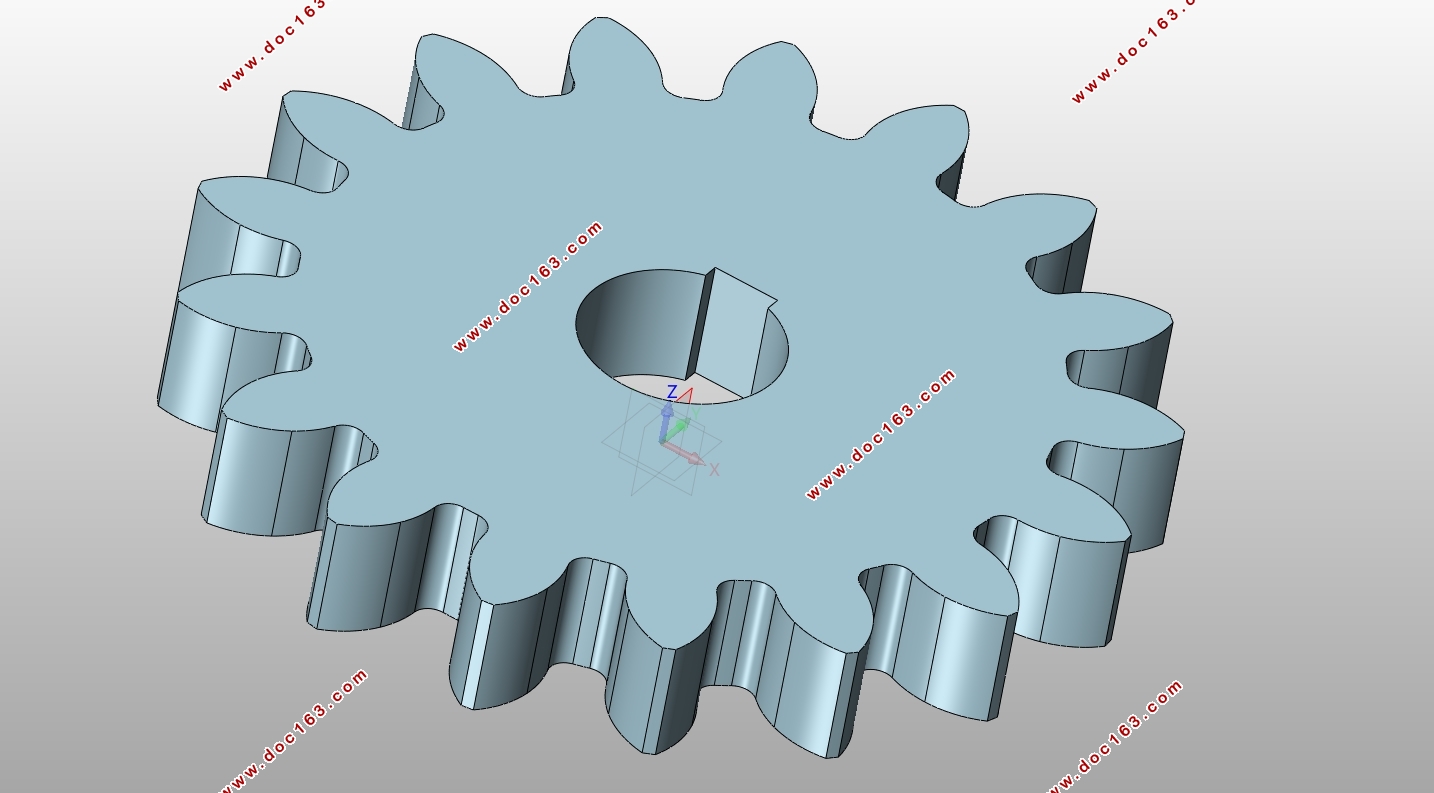

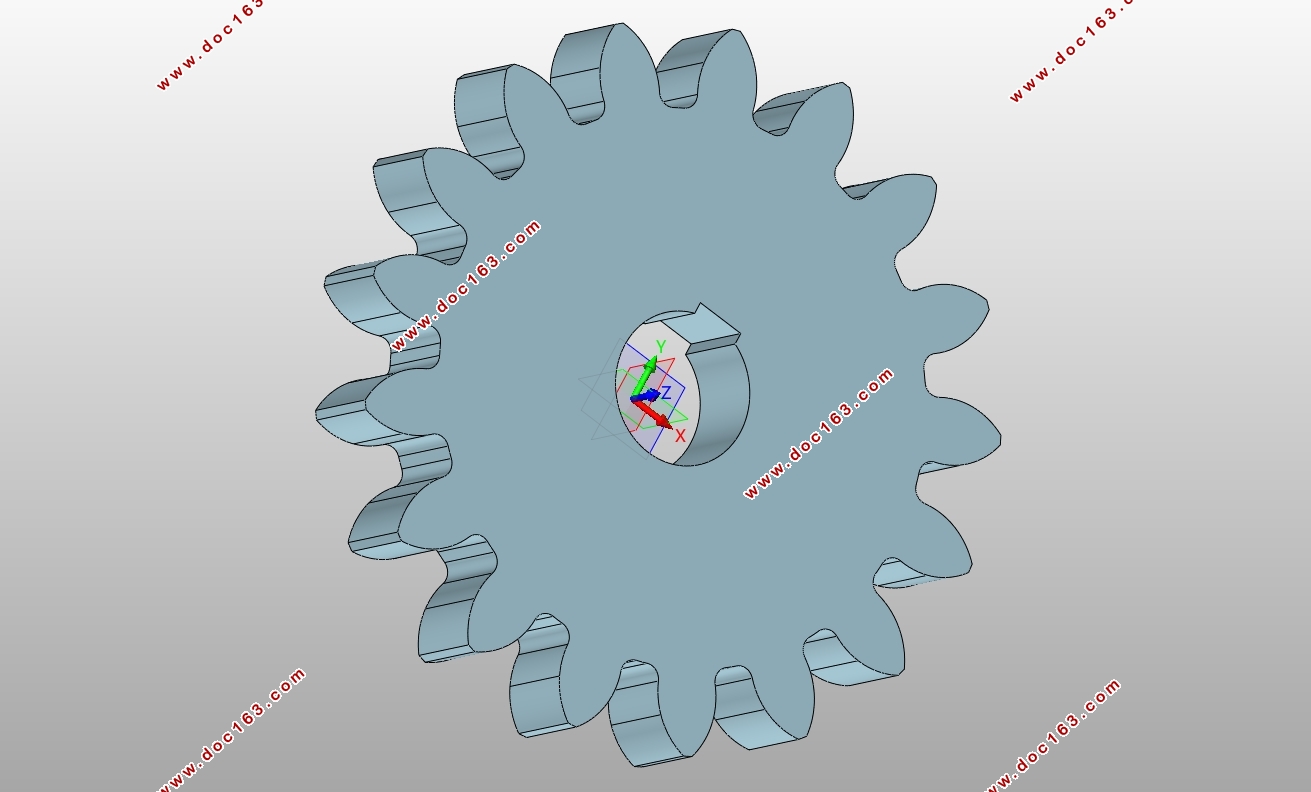

此课题的研究方向是在PRO/E软件中进行直齿轮齿铣削加工的仿真模拟,在研究过程中选择一个标准齿轮,先用PRO/E建模,在利用NC模块进行加工模拟。

关键字:PRO/ENGINEER; 铣削加工; 齿轮; 仿真模拟 [资料来源:http://Doc163.com]

Abstract

The simulation process is the significance of the design and manufacturing process simulation and check, you can use the software before making the actual processing of the simulation process and the way to get results. You can lose the case in the absence of the actual processing of a variety of negative situations such as over-cutting, tool selection errors, the feed line error, unreasonable way retreat knife, knives and other interference with the control plane bound for effective exposure, thereby easy to solve. Meanwhile simulation process can be more intuitive to show parts molding process, so that the production of parts for production personnel and has direct knowledge of the process from the senses.

PRO / ENGINEER (PRO / E) by the United States Parametric Technology Corporation (PTC) development of CAD / CAM / CAE integration of three-dimensional software. PRO / E software for parameterization is known, is the first application of Parametric Technology who, in the field of 3D modeling software currently occupies an important position. PRO / E and get the recognition and promotion of the industry as a new standard in today's world of mechanical CAD / CAE / CAM field, is now mainstream CAD / CAM CAE one / software, especially in the field of domestic products designed to occupy an important position. [资料来源:http://www.doc163.com]

This research project is to carry out simulation spur gear teeth milling in PRO / E software, select a standard gear in the course of the study, first with PRO / E modeling, using NC machining simulation module.

Keywords: PRO / ENGINEER; milling; gear; simulation

[资料来源:http://Doc163.com]

[资料来源:www.doc163.com]

目录

摘要 2

Abstract 3

1.1基于PRO/E的直齿轮成型铣削加工仿真的国内外研究现状 5

1.1.1基于PRO/E的直齿轮成型铣削加工仿真的概述 5

1.1.2 基于PRO/E的直齿轮成形铣削加工仿真的基本方法 9

1.2 本文主要内容 10

第二章 基于PRO/E的直齿轮铣削加工仿真的基本理论 11

2.1引言 11

2.2 直齿轮铣削加工仿真的基本理论 11

2.2.1 对齿轮及其设计方法的简要回顾 11

2.2.2 仿真加工的现状与发展趋势 14

第三章 PRO/ENGINEER软件说明 15

3.1 引言 15

3.2 具体说明 15

3.2.1 PRO/ENGINEER的功能 15

3.2.2 PRO/ENGINEER的特点 16

第四章 直齿轮铣削加工仿真实例 18

4.1引言 18

4.2 设计加工仿真过程 18 [资料来源:http://Doc163.com]

4.2.1 设计圆柱直齿轮 18

4.2.2 成型铣刀建模 27

4.2.3 完成仿真模拟 28

4.2.4 后期处理 33

4.3 本章小结 35

第五章 总结 36

5.1 总结与展望 36

参考文献 37

致谢 39

[版权所有:http://DOC163.com]

上一篇:基于UG的数控加工鼠标仿真

下一篇:没有了