汽车前轴工字梁热锻件模具的三维设计及热学仿真分析(含CAD零件装配图,CATIA

汽车前轴工字梁热锻件模具的三维设计及热学仿真分析(含CAD零件装配图,CATIA三维图)(任务书,开题报告,论文说明书17000字,CAD图5张,CATIA三维图1张,STP三维图1张)

摘要

目前我国汽车产业处于飞速发展阶段。日益提高的生活水平,制造行业的飞速进步,国家政策的大力扶持使得我国汽车日益普及并受到各行各业的关注,我国已然成为汽车制造大国;随着汽车行业的发展,人们对汽车质量的要求也不断提高,这就对汽车及零部件的制造工艺提出了更高的要求;热锻作为汽车复杂轴类零件的主要成形工艺,其主要优势为成形生产的锻件强度高、韧性好、精度高、复杂度高、生产率高等;由于热锻工艺较为复杂,模具设计是关键,要考虑零部件的成形质量以及设备模具的磨损寿命等因素;为了能够在模具设计阶段就能避免不必要的设计缺陷,CAD/CAE技术被运用到了热锻工艺中,借助他们,我们可以预测热锻时锻件成形质量以及模具磨损程度,从而找到理论上最佳的工艺参数,节约生产成本提高生产效率。

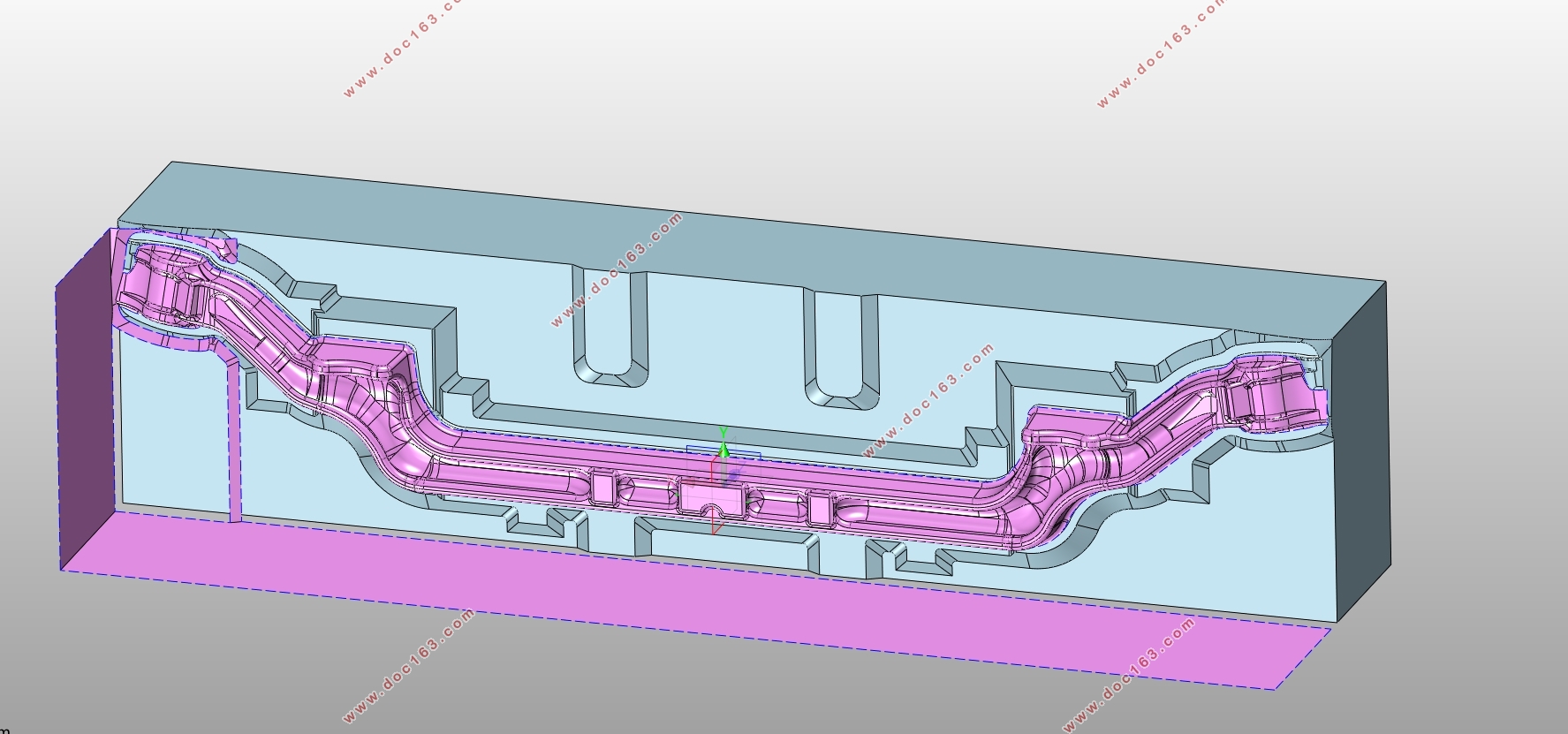

本文以某汽车前轴工字梁的热锻过程为研究对象。根据前轴热锻工艺设计出符合要求的热锻模具,并通过模拟仿真技术得到其相应的模膛和工字梁的温度场以及应力分布,从而分析出该热锻过程最佳的工艺参数得到最优化的热锻方法。首先根据给定的前轴工字梁的相关尺寸参数,设计出符合要求的锻件以及锻模;然后绘制出模具以及锻件的三维模型;之后通过CAE软件DEFORM对热锻这一过程进行模拟,仿真分析的主要研究对象为预锻温度以及锻造速度,研究它们对锻件成型以及模具损耗的影响;设置以上两个研究对象为变量,在多组模拟后,通过对模拟数值的比对,得到最优化的锻造温度(1200℃)以及锻造速度(40mm/s),为实际生产过程中的热锻过程提供有价值的参考。 [资料来源:http://doc163.com]

关键词:热锻、热锻模具、工艺优化、数值模拟

Abstract

At present, China's automobile industry is in a rapid development stage. Rising living standards, the rapid progress of manufacturing industry, the vigorously support of national policy making, becoming increasingly prevalent in China's automobile and got the attention of all walks of life, our country has become a car manufacturing power; With the development of the automobile industry, people's demand for the quality of automobile has been constantly improved, which puts forward higher requirements for the manufacturing process of automobile and parts. Hot forging, as the main forming process of complex shaft parts, is characterized by high strength, good toughness, high precision, high complexity and high productivity. Due to the complexity of hot forging process, mold design is the key factor to consider the forming quality of parts and the wear life of the equipment mold. In order to be able to in the mold design stage can avoid unnecessary design flaws, the CAD/CAE technology has been applied to the hot forging process, with the help of them, we can predict when the hot forging forming quality and mould wear degree, so as to find the best process parameters, theoretically to save the cost of production to improve production efficiency.

In this paper, through the analysis of the hot forging process of the front axle of a car, the temperature field and stress distribution of the die bore and the I-beam are obtained by the simulation technology, and the optimum process parameters of the hot forging process are analyzed. First, according to the related dimension parameters of the given front axle, the forging and forging die, including pre forging, final forging and three stages of billet are designed, and then the 3D model of the die and the forging is designed. Then the hot forging process is simulated by the CAE software DEFORM, and the simulation process is set up. The temperature and forging speed are simulated with two variables, and the influence of the above two variables on the die loss and the forming of the forging is studied. Finally, the optimum forging temperature and forging speed are obtained through the comparison of the simulated numerical values, and the simulation of the above two variables is simulated. It provides a valuable reference for the hot forging process in the actual production process.

[资料来源:https://www.doc163.com]

Key Words: Hot forging, Hot forging die, Process optimization, Numerical simulation

零件工艺性分析

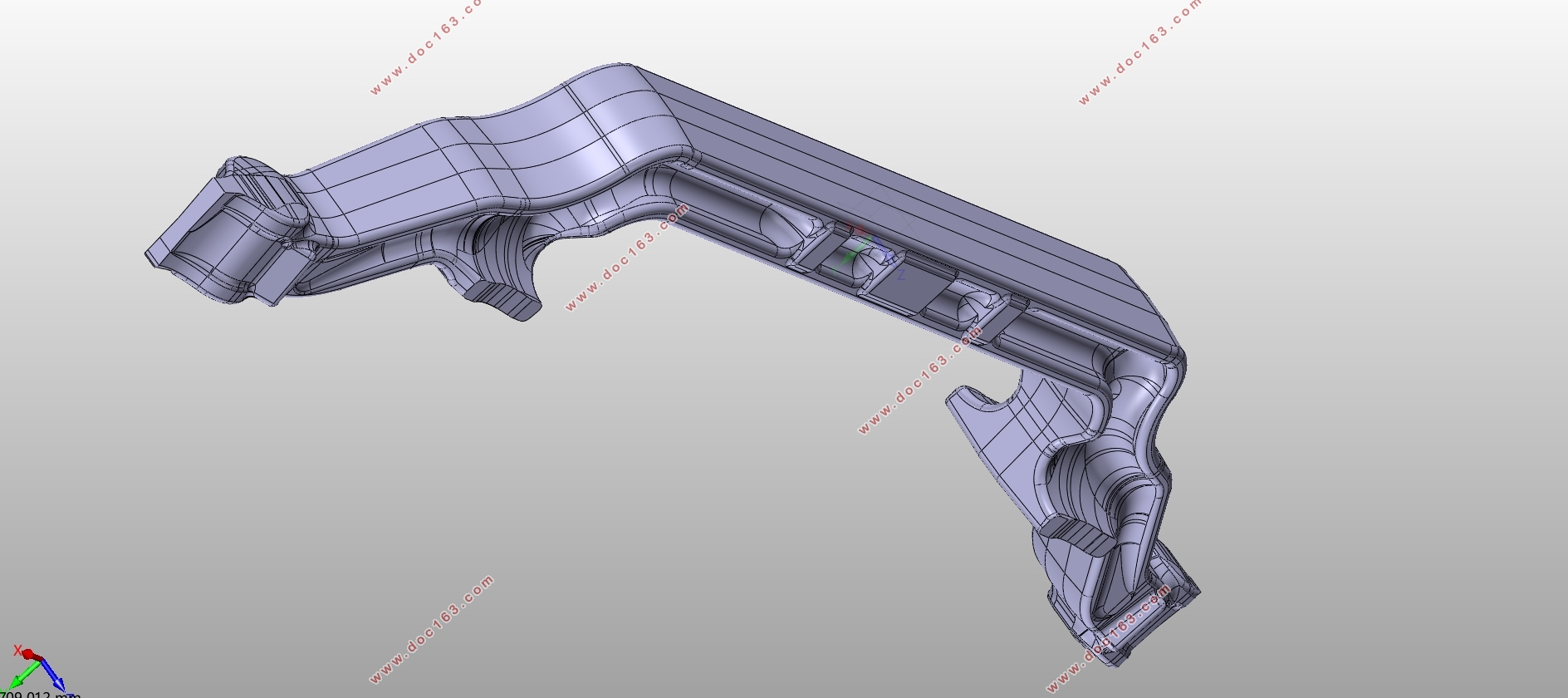

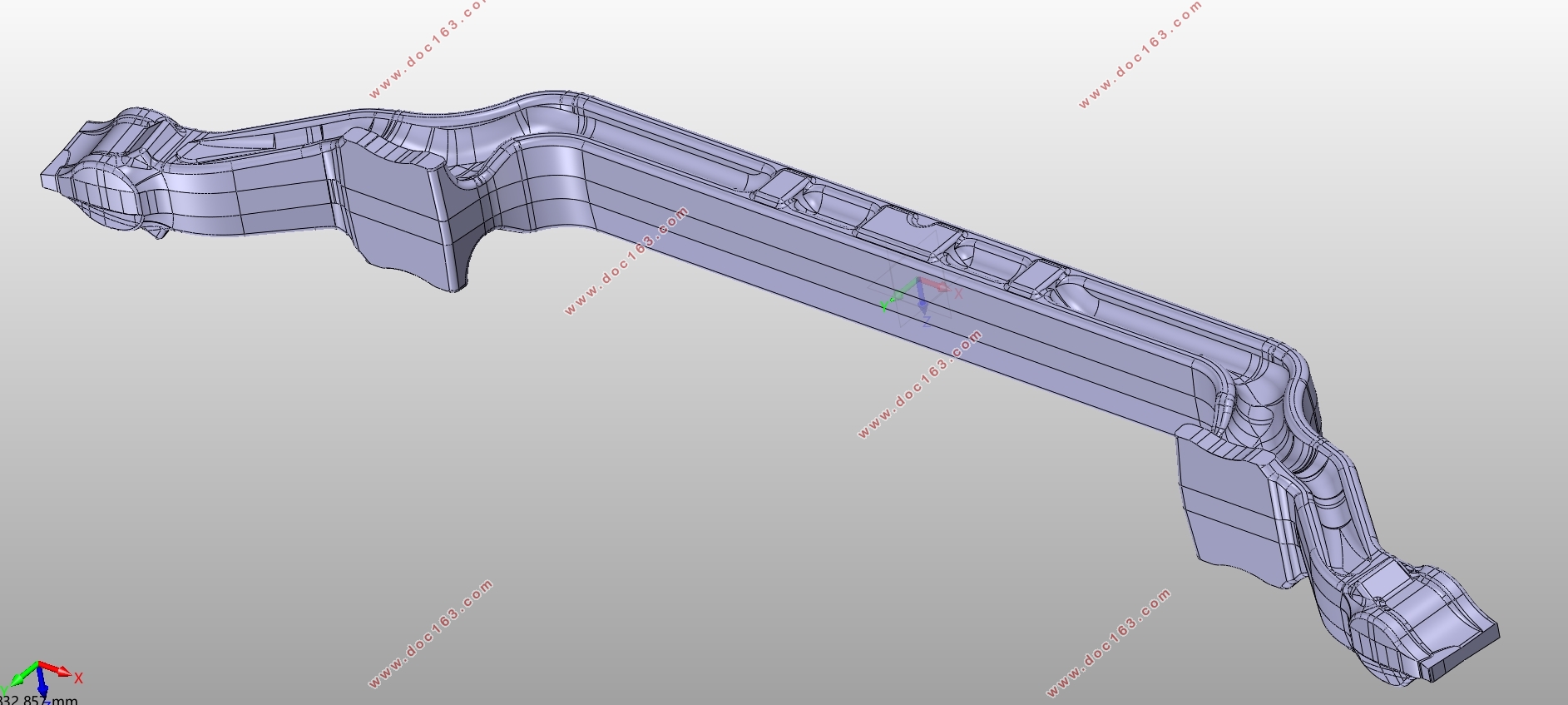

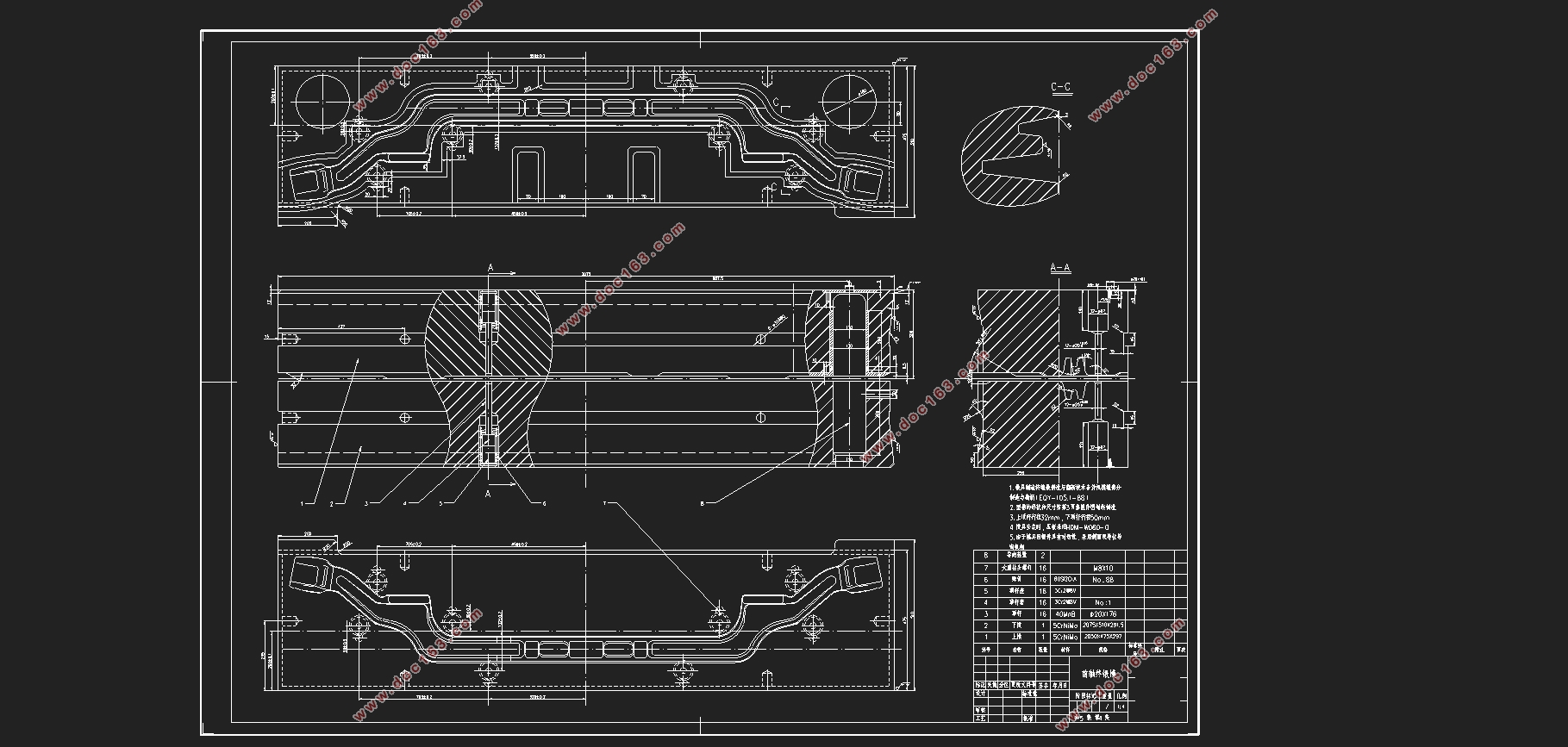

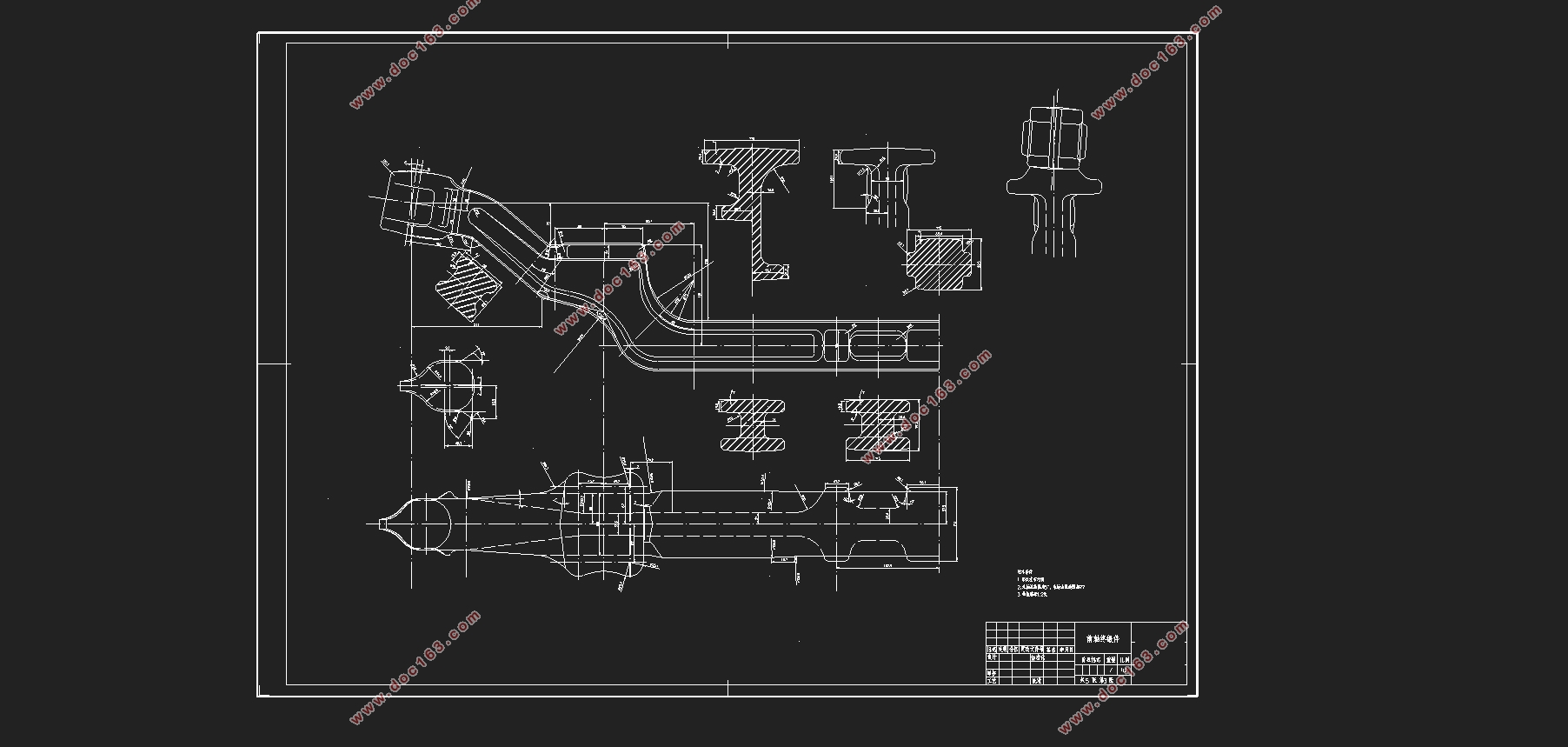

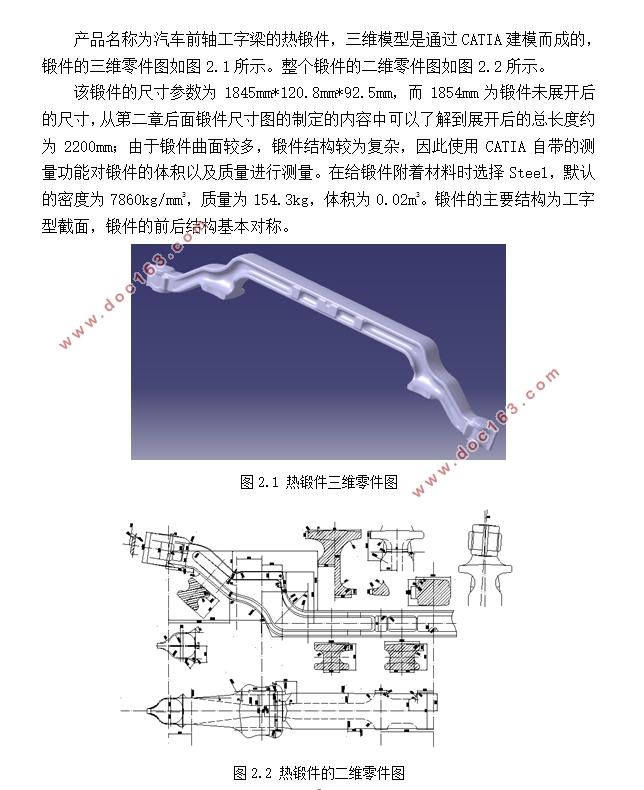

产品名称为汽车前轴工字梁的热锻件,三维模型是通过CATIA建模而成的,锻件的三维零件图如图2.1所示。整个锻件的二维零件图如图2.2所示。

该锻件的尺寸参数为1845mm*120.8mm*92.5mm,而1854mm为锻件未展开后的尺寸,从第二章后面锻件尺寸图的制定的内容中可以了解到展开后的总长度约为2200mm;由于锻件曲面较多,锻件结构较为复杂,因此使用CATIA自带的测量功能对锻件的体积以及质量进行测量。在给锻件附着材料时选择Steel,默认的密度为7860kg/mm3,质量为154.3kg,体积为0.02m3。锻件的主要结构为工字型截面,锻件的前后结构基本对称。

对热锻件的质量要求:保证锻件尺寸精度满足要求;锻件表面缺陷不应超过GB/T12362的规定,但锻件非加工表面存在裂纹时,应打磨消除;锻件表面不应出现过烧现象,即不能出现氧化皮,若出现的话需清理;表面清理方式由抛丸、喷砂、滚筒清理等。

[资料来源:http://doc163.com]

[来源:http://Doc163.com]

[来源:http://Doc163.com]

目录

第1章 绪论 1

1.1课题研究的背景及意义 1

1.1.1汽车行业的发展情况 1

1.1.2热锻工艺在汽车零部件上的应用 1

1.1.3数值模拟技术在热锻工艺上的作用 2

1.2国内外研究现状 2

1.2.1热锻模的发展现状与趋势 2

1.2.2热锻模拟仿真技术的发展现状与趋势 3

1.3课题研究内容与目标 3

第2章 汽车前轴热锻模具设计 5

2.1零件工艺性分析 5

2.2热锻模具总体设计流程 6

2.3热锻模设计与模具寿命的关系 6

2.4热锻模设计方案的确定 8

2.4.1锻件图的制定 8

2.4.2变形工步、工步图设计以及毛坯尺寸的计算 10

2.4.3制坯模膛的设计(拔长、滚压) 14

2.4.4终锻模膛的设计 16

2.4.5预锻模膛的设计 17

第3章 锻造过程有限元仿真分析数学基础 19

3.1. 刚塑性有限元法 19

3.2. 锻造过程塑性成形模拟算法基础 20

3.2.1插值问题 20

[资料来源:https://www.doc163.com]

3.2.2模拟软件中的算法流程 21

第4章 汽车前轴热锻过程的模拟仿真 22

4.1. DEFORM软件分析内容 22

4.2 DEFORM-3D模拟分析 22

4.2.1模拟方案设计 22

4.2.2模拟过程 23

4.3模拟结果分析 33

4.3.1预锻温度的影响 33

4.3.2锻造速度的影响 41

第5章 总结与展望 46

参考文献 47

致谢 49

[资料来源:www.doc163.com]

上一篇:HTD16塑料斜齿轮注射成型工艺分析与模具设计(含CAD图,UG三维图)

下一篇:座盆骨架中间冲压板成型工艺分析与模具设计(含CAD零件图装配图)