塑料瓶盖模具设计及其型腔仿真加工(CAD,Proe,抽芯,工艺卡)

塑料瓶盖模具设计及其型腔仿真加工(CAD,Proe,抽芯,工艺卡)(任务书,开题报告,中期检查表,外文翻译,论文说明书13000字,CAD图24张,Proe三维图,仿真,工艺卡,工序卡)

摘要:注塑模具是现在所有塑料模具中使用最广的模具,能够成型复杂的高精度的塑料制品。本课题是对塑料瓶盖模具设计并分析加工工艺。

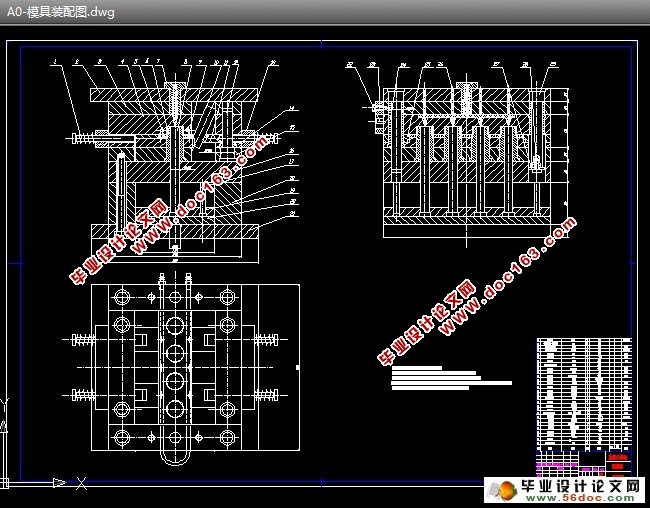

本模具考虑到年产量、工厂的设备及塑件的精度要求,选择一模四腔结构。以瓶盖主体和防伪圈之间的面作为分型面,使制品强制脱模。流道采用带环形冷料穴,脱模时方便将主流道凝料和塑件带出,确保熔融塑料几乎能同时到达每个型腔的进料口。为了使动、定模能够准确地动作, 导向定位机构利用导柱与导套的配合。顶出机构是推杆推出的一次脱出机构。考虑到零件的位置关系,冷却水道采用循环式分布,以便冷却均匀、快速。

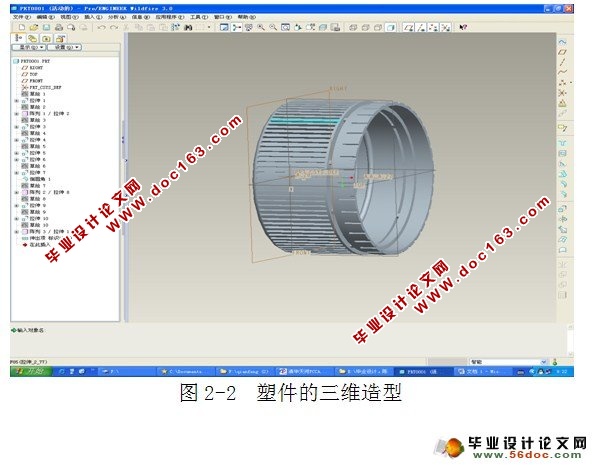

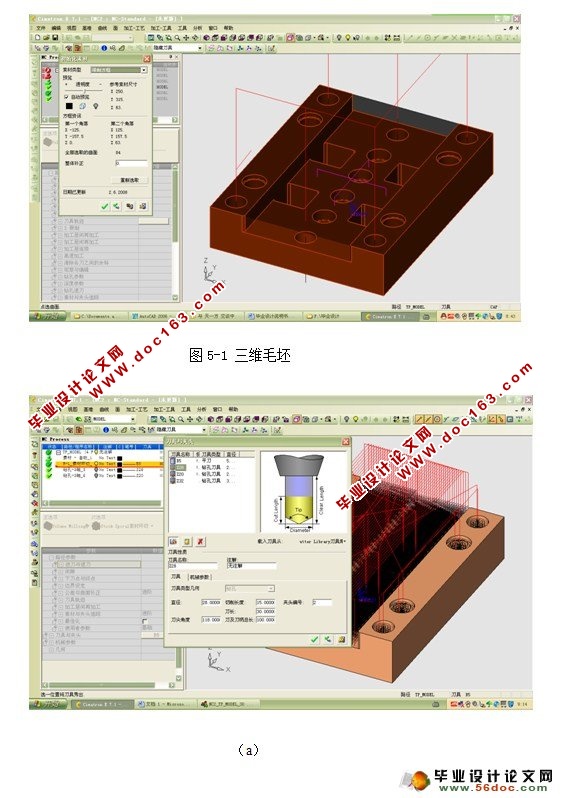

采用Pro/E来实现塑料瓶盖三维设计及模具成型零件设计,分析制件的成型质量和完成分型面的设计,再采用CIMATRION来实现其数控仿真的加工,并在产品设计及模具装配过程中,辅助以必要的理论计算,将数字化设计与理论计算结合起来,可以大大缩短产品研发周期、模具设计周期,提高产品设计及模具设计的准确性、产品成型质量,降低产品研发、模具设计成本。在设计过程中制定了合理的工艺方案,满足了大批量生产要求。同时,还编制了详细的工艺文件来保证模具的顺利加工及制品的生产。

[资料来源:http://doc163.com]

通过合理的设计,本模具满足生产与应用的要求。

关键词:注塑模具;加工工艺分析;Pro/E。

The Design and Simulation

Processing of Mold for Plastic Caps

Abstract:At present ,injection molding is the plastics mould that has being used most extensively , it can mold the complex and high accurate plastic product. The Subject is about the design of the plastic caps and simulation processing.

Considering the annual output, the equipment of the factory and the requirement of precision of the plastic product, four cavities in a mould. The middle horizontal surface of the goods was To cap the main circle and security between the surface as a type face, so that mandatory Stripping products. The runner is designed to be balanced and symmetrical distribution, ensure that melting plastic could reach each cavity’s gate almost.. Suspension and Positioning mechanism use matched guide pillar and guide sleeve to make movable mould, fixed mould to work accurately. The knockouts uses once ejecting mechanism that lifter pushes out. By the relation of the position of each part, cooling channels are designed to straight channels to cool effectively, quickly. [来源:http://www.doc163.com]

With Pro/Engineer,MoldFlow to implement three-dimensional design and mold volume design of the Plastic caps, and shaping quality of part was analyzed and the parting line was designed by Pro/Engineer, then utilized CIMATRION to accomplish the assemblage of the mold with the assistance of essential theory calculate mixed with figure design. It would not only shorten the cycle of product research and mold design, and improve the preciseness and the product shaping quality, but also lower the cost of the research. Having made the rational craft scheme in the design process ,so it has met the requirement of producing in enormous quantities. Moreover, it also prepared a detailed document to ensure that the process for the smooth processing of mold and apparel production.

Through the rational design, It has meet the production and application of the requirements.

Key words: injection mould;process analysis;Pro/E.

课题研究的主要内容:

(1)产品的注塑加工工艺

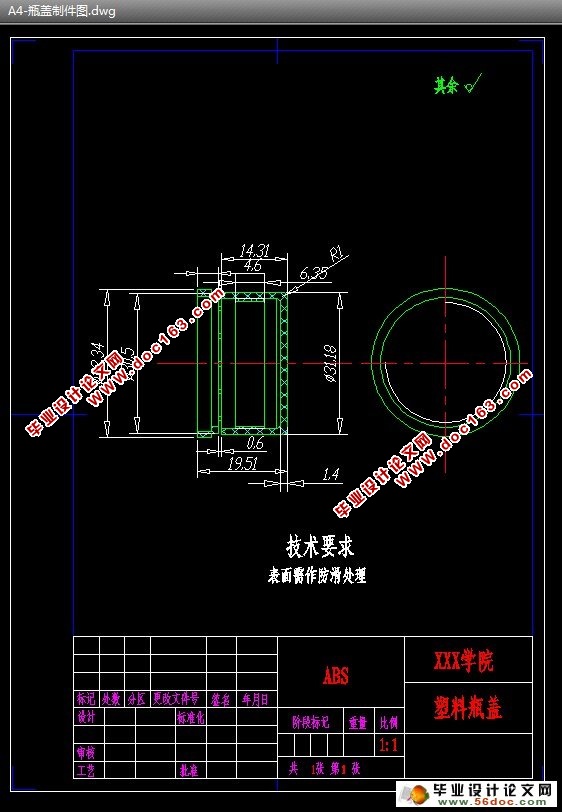

(2)制品测绘、工程图绘制、三维造型及结构优化 [资料来源:Doc163.com]

(3)制品模具设计(全套工程图及三维造型)

(4)上下型腔的加工工艺分析、工艺规程、数控仿真加工及下型腔的工艺卡片。

[来源:http://www.doc163.com]

[资料来源:www.doc163.com]

[资料来源:www.doc163.com]

目录

1前言 1

1.1课题内容 1

1.2课题背景 1

1.3模具国内外发展概况 1

1.4课题的来源及要求 2

2模具方案及制品设计 3

2.1总体方案设计 3

2.2塑件的测绘 3

2.3塑件的造型 4

2.4塑件的材料选择与分析 5

2.5塑件尺寸精度 5

2.6模具材料的选择 5

2.7脱模斜度 6

2.8型腔数目的确定 6

2.9注射机的选择 7

3具体设计说明 8

3.1分型面的确定 8

3.2浇注系统的设计 9 [资料来源:http://Doc163.com]

3.3主流道的设计 9

3.4分流道的设计 10

3.5浇口套的设计 11

3.6冷却装置设计 11

3.7推出机构设计 12

3.8推杆 13

3.9复位杆 13

3.10 导向装置 13

3.11 侧抽芯的设计 13

3.12确定各模板尺寸 14

3.13凸凹模结构形式 14

3.14 注射机技术参数的校核 15

3.15 零件强度计算及校核 16

4 模具的三维造型 19

4.1典型零件的造型造型 19

4.2模架的三维造型 19

5 型腔工艺分析及加工仿真 22

6 结论 26

参考文献 27

致谢 28

附录 29

[资料来源:http://Doc163.com]

上一篇:浅盒形件拉深工艺及模具设计

下一篇:玩具手机后盖的塑件注射模具设计(含CAD零件图和装配图)