热泵干燥装置电控系统设计

热泵干燥装置电控系统设计(含配电图)(论文12000字)

摘要

我国是农业大国,每年果蔬的产量巨大,其中需要进行干燥加工的比重很大,但目前我国对蔬菜干燥加工的技术还是比较落后,本课题将热泵干燥技术、自动检测技术、实时监控技术应用于蔬菜的干燥加工过程当中,重点开发设计了一个热泵干燥装置的电控系统,对蔬菜的干燥加工过程进行实时监控。

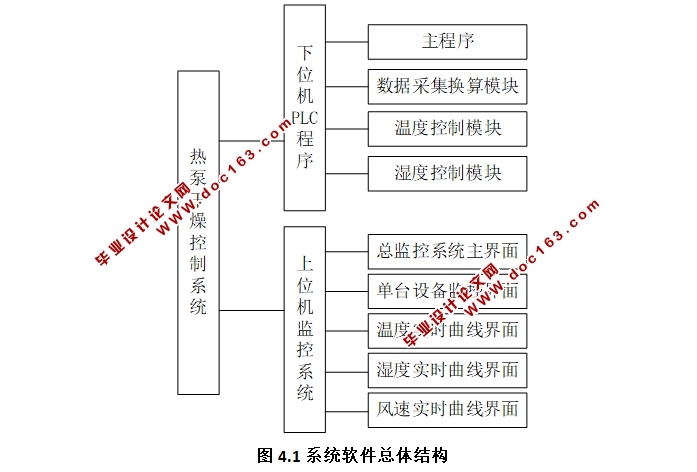

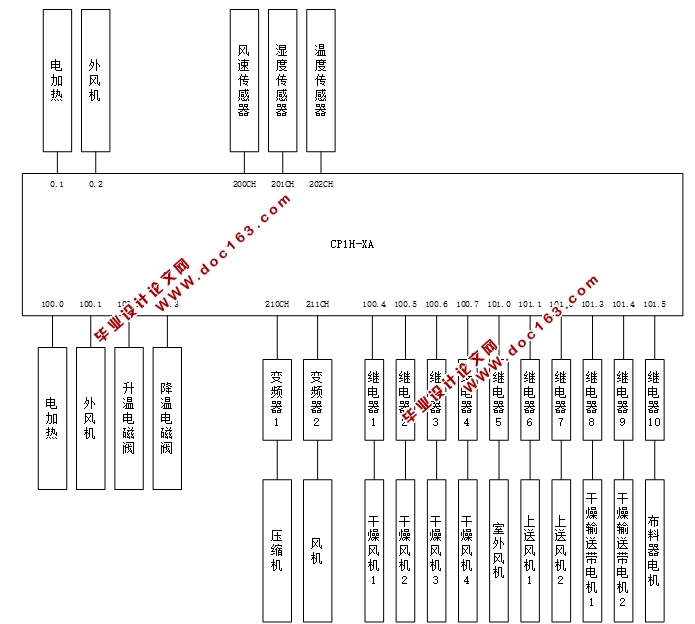

本文重点设计了一个热泵干燥的电控系统,该系统主要由热泵干燥装置、下位机控制系统和上位机监控系统组成。热泵干燥装置由压缩机、冷凝器、蒸发器、膨胀阀、干燥风机等组成。下位机控制系统由PLC、PLC模拟量扩展模块和传感器组成,传感器将采集到的温度、湿度、风速等模拟量信号传输到PLC模拟量输入模块,并转换成数字信号储存。下位机PLC作为现场控制级,利用PLC编程软件编写用户程序完成依据热泵干燥系统工艺要求多台设备多批次启动和停止、干燥过程温度的测量与调整、湿度的测量、过热能量的发散、故障的识别与处理,还有同上位机的RS485通讯。上位机监控系统作为管理级,采用可编程终端人机触摸屏,通过编写触摸屏自带的组态软件,实现对现场数据的实时记录和处理,包括运行数据的显示、参数的设定、报警信息的显示和查询等功能。本文设计的电控系统实现了蔬菜脱水加工的自动化,从而降低操作成本,提高产品品质。 [资料来源:Doc163.com]

关键词:蔬菜脱水;热泵干燥;可编程控制器;可编程终端;过程监控

Abstract

China is a big agricultural country , the annual giant vegetable production , which requires a large proportion of the drying process , but our vegetable drying process technology is still relatively backward .This subject combines the heat pump drying technology with automatically detection technology and real-time monitoring technology for the drying process of vegetables , focusing on design of the electronic control system of a heat pump dryer for drying vegetables processing with the real-time monitoring.

This article focuses on the design of a heat pump drying of electronic control system, which mainly consists of a heat pump dryer , lower machine control systems and PC monitoring system. The heat pump drying equipment consists of compressor , condenser , evaporator, expansion valve , drying fan. Lower position machine control system consists of PLC, PLC analog expansion modules and sensors , the sensor will collect temperature, humidity , wind speed and other analog signals to PLC analog input module and converted into a digital signal storage .Lower position machine as a field control level , user can write PLC programming software to complete multiple devices multiple batches starting and stopping , measuring and adjusting the temperature of the drying process , measuring humidity , thermal energy divergence, failure identification, as well as RS485 communication Ditto bit machine, whichin accordance with the requirements of heat pump drying system processes. PC monitoring system as a management level ,using the programmable terminal HMI touch screen, touch screen comes through the preparation of the configuration software, on-site real-time data recording and processing , including setting display operational data , parameters, alarm information display and query functions. This design of the electronic control system to achieve the automated processing of dehydrated vegetables , thereby reducing operating costs and improve product quality. [来源:http://www.doc163.com]

Keywords:dehydrated vegetables ; heat pump drying; programmable logic controller;programmable terminal; process monitoring

[资料来源:https://www.doc163.com]

目录

摘要 1

Abstract 2

第一章绪论 3

1.1课题的研究背景和研究意义 3

1.2热泵干燥的国内外研究现状 3

1.2.1热泵干燥的国外研究现状 3

1.2.2热泵干燥的国内研究现状 4

1.3方案背景技术简介 4

1.3.1可编程控制器(PLC)的现状与发展 4

1.3.2可编程终端人机(PT)的发展现状 5

1.4本课题的主要研究内容 6

1.5本章小结 6 [资料来源:www.doc163.com]

第二章热泵干燥装置系统特性及控制要求 6

2.1热泵干燥技术简介 6

2.2热泵干燥装置的工作原理 7

2.3热泵干燥装置的结构形式 7

2.4热泵干燥装置的控制要求 8

第三章热泵干燥装置电控系统的硬件设计 8

3.1系统概述 8

3.2热泵干燥装置电控系统的方案设计 9

3.3电控系统的下位机硬件设计 10

3.3.1下位机(PLC) 10

3.3.2上位机 13

3.3.3内置模拟量输入输出模块 14

3.3.4传感器的选型 15

3.3.5变频器 16

3.3.6继电器 17

3.3.7电磁阀 17

3.3.8 RS485通讯接口 17

3.4热泵干燥装置电控系统的电路连接 18

3.4.1下位机与继电器的连接 18

3.4.2模拟量模块与传感器的连接 19

3.4.3上位机与下位机的通讯接口 20 [资料来源:https://www.doc163.com]

第四章热泵干燥装置电控系统的软件设计 20

4.1下位机PLC程序设计 21

4.2上位机监控系统的设计 23

4.3本章小结 25

第五章结论与展望 26

5.1主要研究工作及结论 26

5.2本课题的展望 26

参考文献 27

致谢 29

[来源:http://www.doc163.com]

上一篇:机械手自动控制系统的PLC实现方法研究(含CAD流程图接线图)

下一篇:基于PLC控制装卸料液压工业机械手的设计(含CAD零件图装配图)