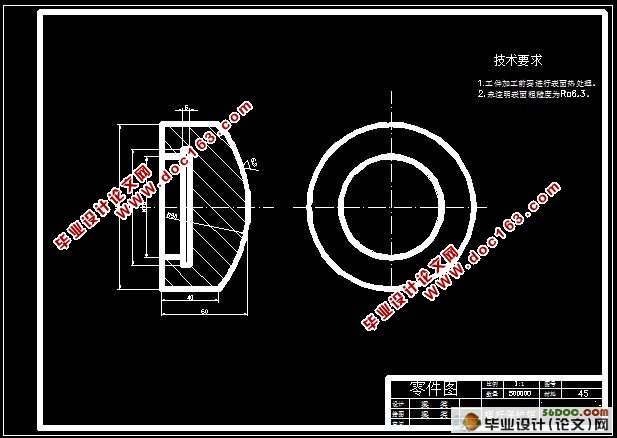

球面零件专用切削机床设计(含零件图,电气原理图和装配图)

球面零件专用切削机床设计(含零件图,电气原理图和装配图)(任务书,论文说明书14000字,cad图纸)

摘 要

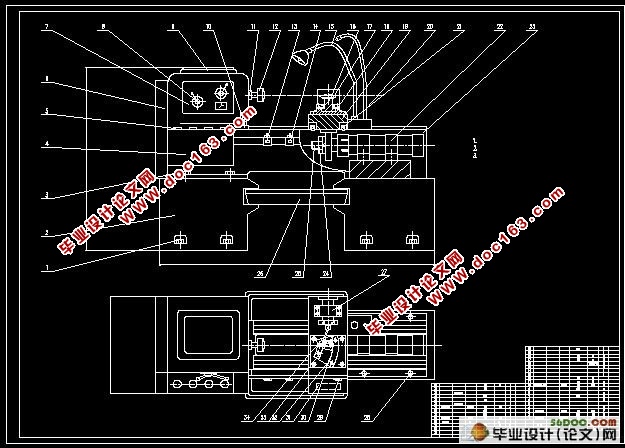

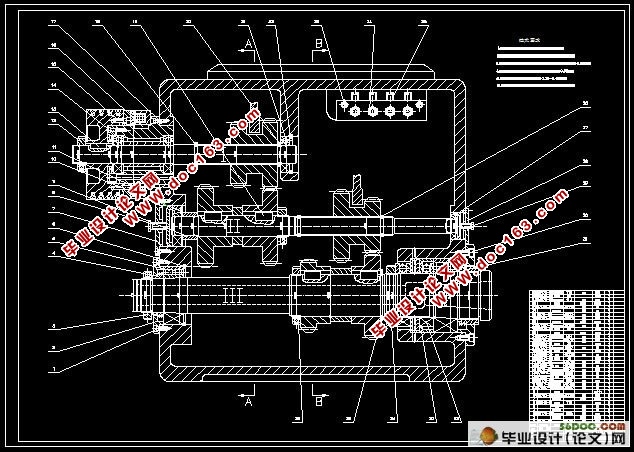

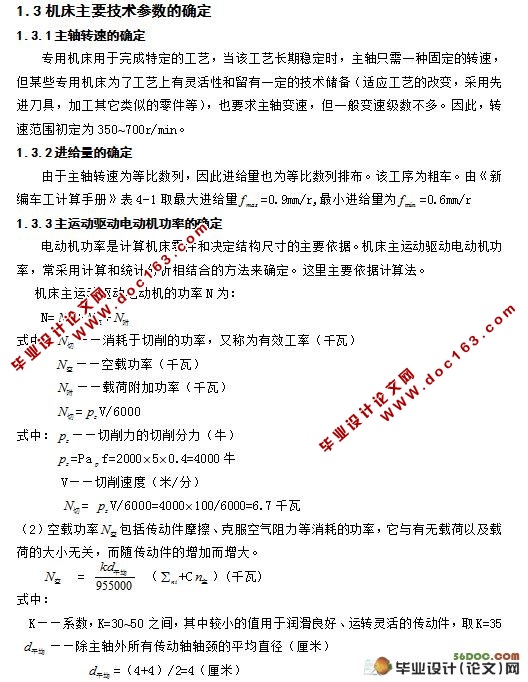

我这次毕业设计的题目是球面切削专用设备。该专用设备的设计方案主要依据仿形车削的工作原理。其中包括床头箱的设计和进给机构的设计。床头箱要满足4级变速,并能在更换工件时迅速制动。进给机构包括纵向进给液压缸、横向进给液压缸,曲柄滑块机构和型槽。

车刀的纵、横两方向移动均采用液压驱动,因此液压系统的设计是否合理直接影响到机床的工作性能。在液压系统中,床鞍及滑块的运动方向分别由各自的三位四通电磁换向阀控制,其运动速度由安装在各自油缸回油路上的调速阀及二位二通电磁换向阀联合控制。由溢流阀调整系统油压,调整后的数值可由压力表测出。

该设备的电气部分采用PLC控制。它可靠性高,抗干扰能力强,结构简单,功耗低,并由实际情况考虑,决定采用F1三菱系列PLC。

一个好的专用设备应该达到:1)提高生产率和工人劳动生产率,显著减轻工人劳动强.2)工作稳定可靠,使用寿命长。3)易于维修,成本低。根据理论验证,上述方案基本达到要求。

关键词: 仿形车床;液压系统;PLC

Abstract

The topic of this graduation project of mine is that the sphere cuts the dedicated device . Operation principle of main basis profile modelling turning of design plan of this dedicated device . Include the design of the bedside case and enter to the design of the organization. The bedside case wants satisfied 4 grades to change speed, and can apply the brake rapidly while changing the work piece . Enter to the organization including getting vertical, trough of slippery organizations of crank and type.

The vertical , two horizontal directions of the lathe tool move and adopt the hydraulic pressure to urge , so the design systematic in hydraulic pressure influences the working performance of the lathe directly rationally. Among hydraulic pressure system, bed saddle slip sport direction of piece control by one's own 3 electromagnetic reversing valve of Stone separately, sport its speed install in each cylinder going back to transfer speed valve and 2 electromagnetic reversing valves 2 times jointly control oil passaging. Is it flow valve adjust systematic oil pressure , adjust number value after can be measured by the manometer to overflow.

A fine dedicated device should reach : 1)Boost productivity and worker labor productivity, lighten worker work strong notably. 2)It is reliable that the work is steady, have long performance life. 3)Easy to maintain, with low costs. Verify according to theory above-mentioned schemes reach demanding basically.

Keyword: copying lathe ; hydraulic pressure system ;PLC