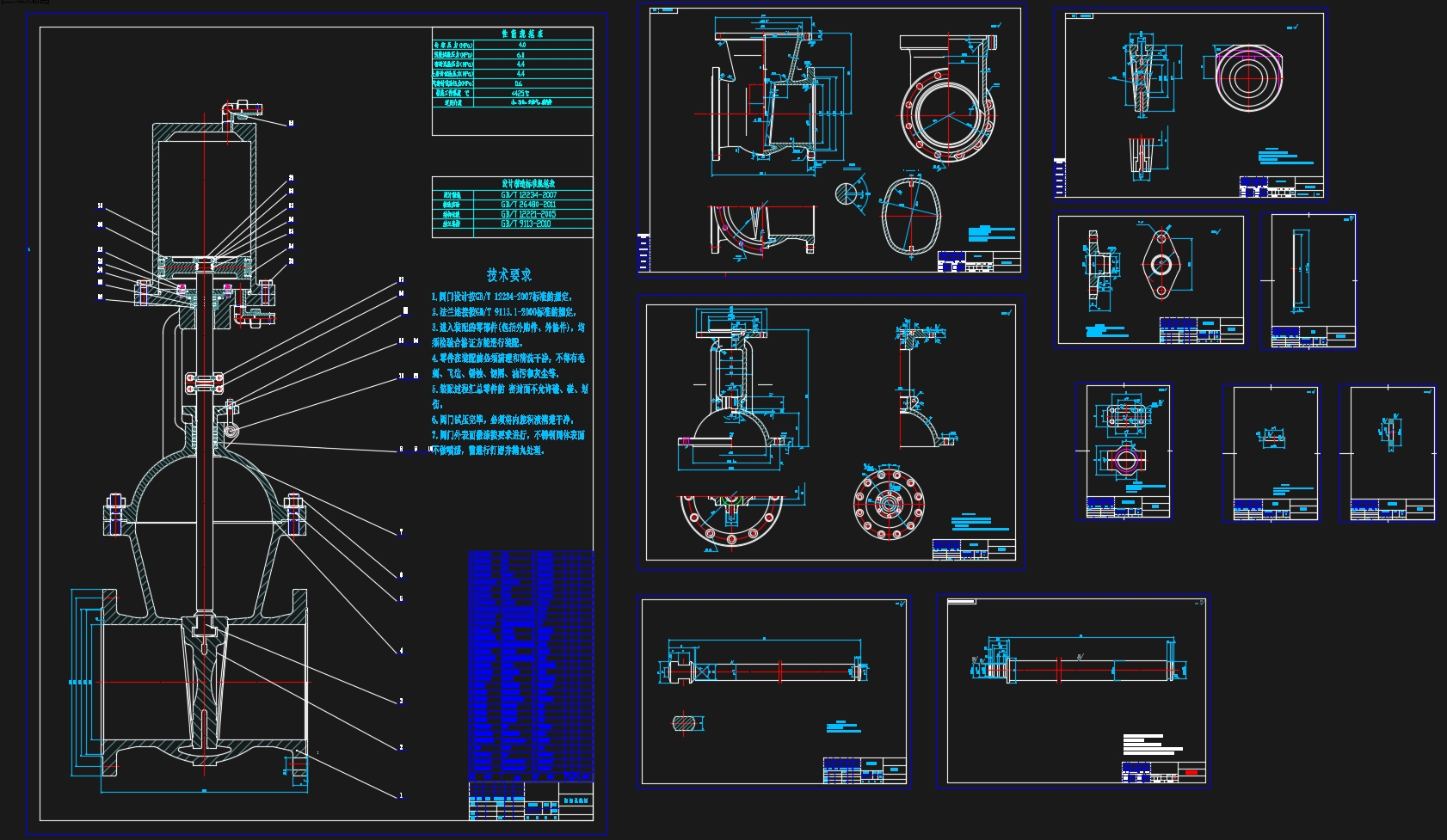

PN40DN250液动楔式闸阀设计(含CAD零件图装配图)

PN40DN250液动楔式闸阀设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书10000字,CAD图纸11张)

摘 要

本论文课题是设计闸阀的结构 。闸阀主要由阀体、阀盖、闸板、阀杆、等装置组成,其结构在阀体内类似闸阀一样的板状物与无相配的两阀座(或单阀座)之间垂直于流体移动,从而打开或切断流道。用它做启闭使用,并在全开时整个流道直通的作用。闸阀适用范围广泛,主要应用于石油、化工、电力、医药、火力等行业。

本文是针对闸阀的设计展开阐述。该闸阀设计为法兰连接形式的软密封结构,阀体与阀座采用螺纹阀座,阀盖与支架采用分体结构。闸阀结构设计的基本内容为对闸阀标准的了解、阀体壁厚计算与校核、阀体尺寸的确定、密封比压计算、总转矩计算、阀杆强度校核等; 闸阀的检查和试验、安装、维护、保养和使用注意事项进行适当说明。

关键词: 闸阀,结构与工艺, 密封 ,密封比压 ,试验

Abstract

The topic of this paper is the design of gate valve. The valve mainly by the valve body, valve cover, gate, stem,devices, two seat plate structure in the body similar to the gate of the same and non matching (or single seat)between perpendicular to the fluid movement, so as to open or cut off the channel. Use it to make the opening and closing, and when in full flow through the whole effect. The valve is widely applied, mainly used in petroleum,chemical, electric power, medical, fire and other industries.

This paper is discussed according to the valve design. The valve is designed for soft seal structure of the flange connection, the valve body and the valve seat by screw valve seat, valve cover and the bracket adopts a split structure. Gate valve structure design of the basic content of valve standard understanding, the wall thickness of the valve body, the valve body for calculating and checking to determine the size, sealing pressure than the calculation,the total torque calculation, the stem strength check; check and test, valve installation, maintenance, maintenanceand matters needing attention for an appropriate explanation.

Keywords: gate valve, the sealing structure and process,, seal than the pressure, test

3.6 闸阀的常用压力

闸阀压力等级1.6-6.4MPa

3.7 闸阀的常用温度

常用温度为-29度-425度

[资料来源:http://Doc163.com]

目 录

PN40DN250液动楔式闸阀设计 I

Abstract II

第一章 绪论 1

1主要外形结构与尺寸 1

2 引言 1

3 闸阀的定义 2

3.1 闸阀的种类 3 [资料来源:www.doc163.com]

3.2 闸阀的密封原理和特点 3

3.2.1 密封原理 3

3.2.2 特点 4

3.3 闸阀优点 4

3.4 闸阀的缺点 5

3.5 闸阀的通径收缩 5

3.6 闸阀的常用压力 5

3.7 闸阀的常用温度 6

3.8 主要标准 6

4型号编制说明 6

5 设计需达到技术要求 7

5.1 阀体 7

5.2阀盖 7

5.3闸板 7

5.4 上密封座 8

5.5 填料垫片 8

第二章 阀门的设计与计算 8

1阀门的设计与计算 8

2 主要零部件材料和设计采用标准 17

3闸阀的检验与试压 17

3.1 含义 17

3.2 闸阀的检查 18 [资料来源:http://doc163.com]

3.2.1 铸件的检查 18

3.2.2 阀门主要尺寸检查 18

4.3 闸阀的压力试验 18

4.3.1壳体强度试验 18

4.3.2密封试验 19

4.3.3上密封试验 19

5 维护、保养、安装和使用的注意事项 19

6 可能发生的故障及消除办法 20

结论 22

参 考 文 献 23

致谢词 24

上一篇:PN40/DN300双缸气动弹性单闸板闸阀设计(含CAD零件图装配图)