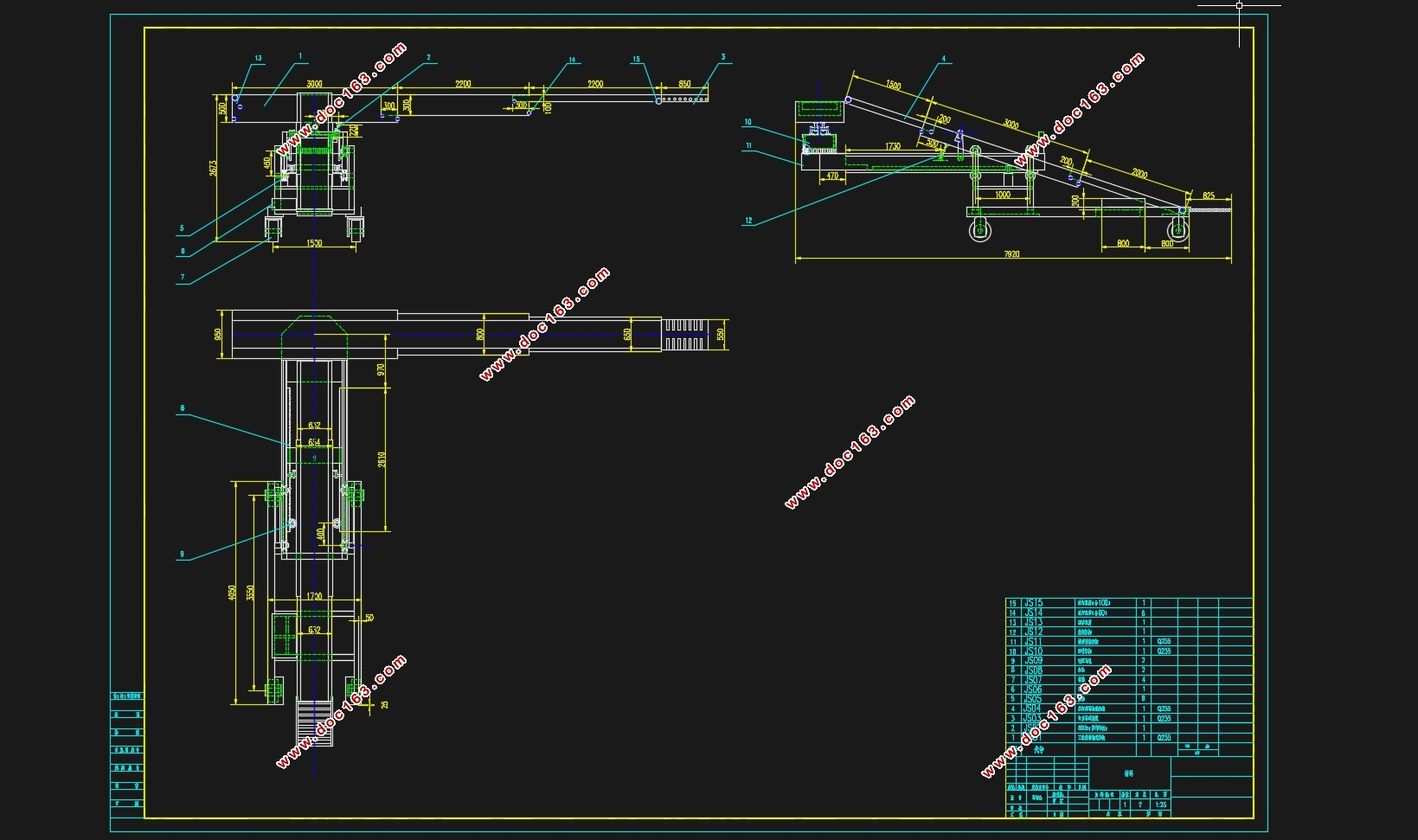

新型自动化袋物装车机皮带机输送系统设计(含CAD图)

新型自动化袋物装车机皮带机输送系统设计(含CAD图)(任务书,开题报告,外文翻译,论文说明书10300字,CAD图3张)

摘 要

目前铁路运输作为我国的重要运输手段,在20世纪90年代以后,铁路运输量呈逐年递增趋势。在铁路运输中棚车又是其中的重要运输工具,它的装载效率直接影响着火车站的货运能力和成本。在现在,中国的棚车装载手段主要还是以人力搬运配合叉车装载为主要方式、只在部分地方开始使用装车机,它的装车效率低、成本高、搬运环境差等等问题日益突显。

本文研究就是为了提出一种专门针对棚车装载的新型装车机。主要是在现有装车机的研究基础之上,进一步提高装载效率、有效解放人力,达到协同工作的目的。本文根据设计要求确定新型自动化装车机的机构型式,对各个机构的特点和工作原理进行分析说明,并对各个机构进行初步设计。其中本文主要提出三级伸缩输送系统的设计,对该机构的工作原理和部件选型进行了较详细讨论和计算,最后通过SolidWorks软件完成该机构的三维建模仿真。

通过本次毕业设计对大学四年所学进行了进一步加深和运用。在设计过程中通过询问老师和与同学交流,使我受益良多。经过本次毕业设计,对我将来进入社会有了更加好的准备。 [资料来源:http://www.doc163.com]

关键词: 袋物;棚车;装车机;三级伸缩皮带机;自动堆码;总体计算;

Abstract

Railway transport as an important means of transportation in our country at present, since the 1990 s, the railway traffic showed a trend of increasing year by year. In railway transportation covered wagon is one of the important means of transport, the loading efficiency directly affects the railway station cargo capacity and cost. In the present, China is still mainly covered wagon loading method in human handling with forklift loading as the main way, only used in parts start loading machine, its loading, low efficiency, high cost, poor handling environment and so on question increasingly highlighted.

In this paper is to propose a covered wagon loading specifically for the new car charger. Mainly based on the research of existing loading machine, further improve the efficiency of loading and human liberation, achieve the goal of collaborative work. In this paper, according to the requirement of design of new type automatic loading machine organization pattern, analyzes the characteristics and working principle of various agencies, and the preliminary design of various agencies. Among them in this paper, we put forward the three levels of telescopic conveyor system design, working principle and components of the organization's selection has carried on the detailed discussion and calculation, finally, SolidWorks software to complete the 3 d modeling and simulation of the institution.

Through the graduation design has carried on the further deepening to university four years learning and use. In the design process by asking the teacher and classmates, I benefit a lot from it. After the graduation design, have more good preparation for my future into society.

Keywords: bag; boxcar;Loading machine; Level 3 telescopic belt conveyor; Automatic stacking; The overall calculation;

2.3新型自动化袋物装车机设计参数

新型自动化袋物装车机设计参数如表2.1所示。

表2.1 设计参数

车厢尺寸 14m*2.9m

车厢距离地面 约高1m

袋物尺寸 750m*400m*150m,50kg/袋

棚车门的尺寸 宽2.5m,高2.8m

装车效率 1200袋/小时

每节车厢载重 60t

[资料来源:http://www.doc163.com]

[资料来源:http://doc163.com]

目 录

第1章 绪论 1

1.1袋物装车机简介 1

1.2国内外研究现状 1

1.3伸缩机构研究现状 1

1.3.1人力制动滚筒伸缩机构 2

1.3.2电动钢绳伸缩机构 2

1.3.3动力链条伸缩机构 2

1.3.4油缸伸缩机构 2

1.4研究目的意义 3

1.5研究内容 3

第2章 新型自动化袋物装车机总体设计 4

2.1新型自动化袋物装车机设计要求 4

2.2新型自动化袋物装车机工作原理和流程 4

2.3新型自动化袋物装车机设计参数 5

2.4新型自动化袋物装车机结构组成 5

2.4.1双向伸缩带式输送机构 6

2.4.5俯仰机构 7

2.4.6行走机构 7

2.4.7卸料堆码机构 7

2.4.8改向立辊装置 7

2.4.9液压站和发电机组 7

[资料来源:http://www.doc163.com]

2.5本章小结 8

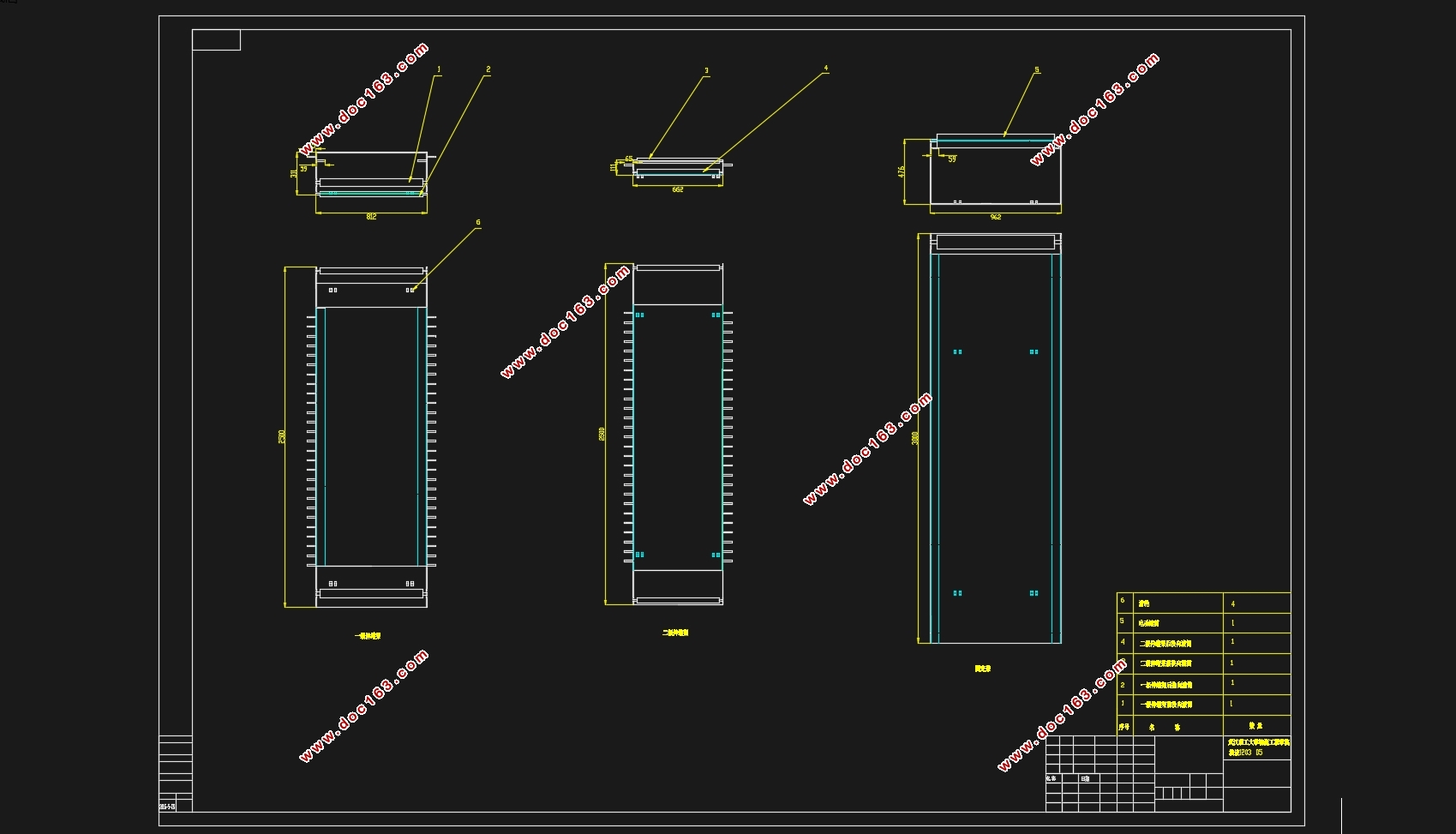

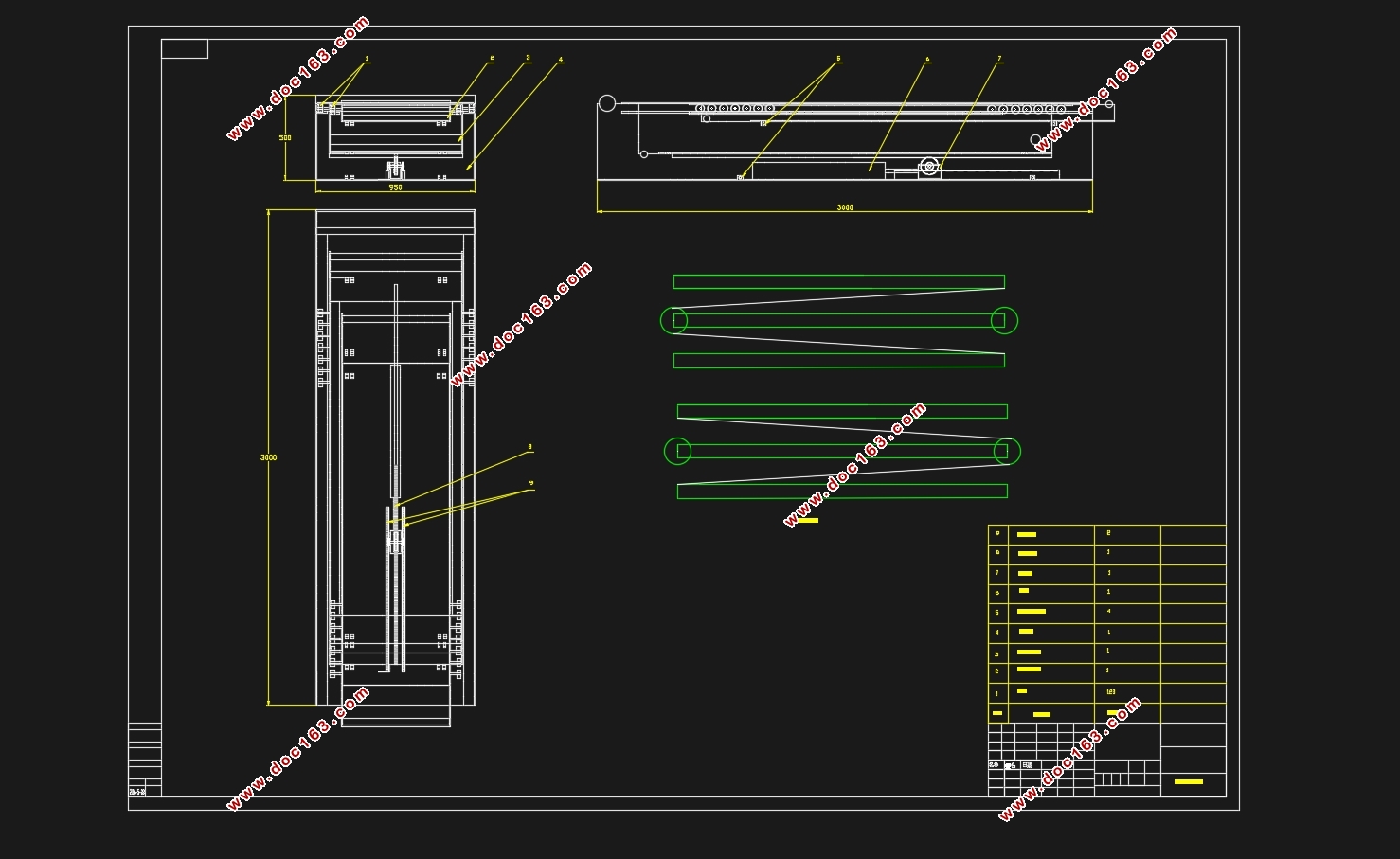

第3章 三级伸缩带式输送系统设计 9

3.1三级伸缩带式输送系统构成 9

3.2伸缩机构原理 9

3.3带式伸缩输送机计算 9

3.3.1初定设计参数 10

3.3.2.由带速、带宽来验算输送能力 10

3.3.3驱动圆周力的计算 10

3.3.4输送机运行功率的计算 12

3.3.5输送带张力计算 13

3.3.6.输送带层数计算 14

3.4带式伸缩输送机驱动方式选型 15

3.5本章小结 15

第4章 三级伸缩输送系统三维仿真建模 17

4.1仿真建模总装配图与各部分图 17

4.2本章小结 19

第5章 总结 20

致谢 21

参考文献 22

上一篇:63T-M平头塔式起重机总体设计(含CAD零件图装配图)

下一篇:CWGS 400型擦窗机总体设计(含PROE三维图)