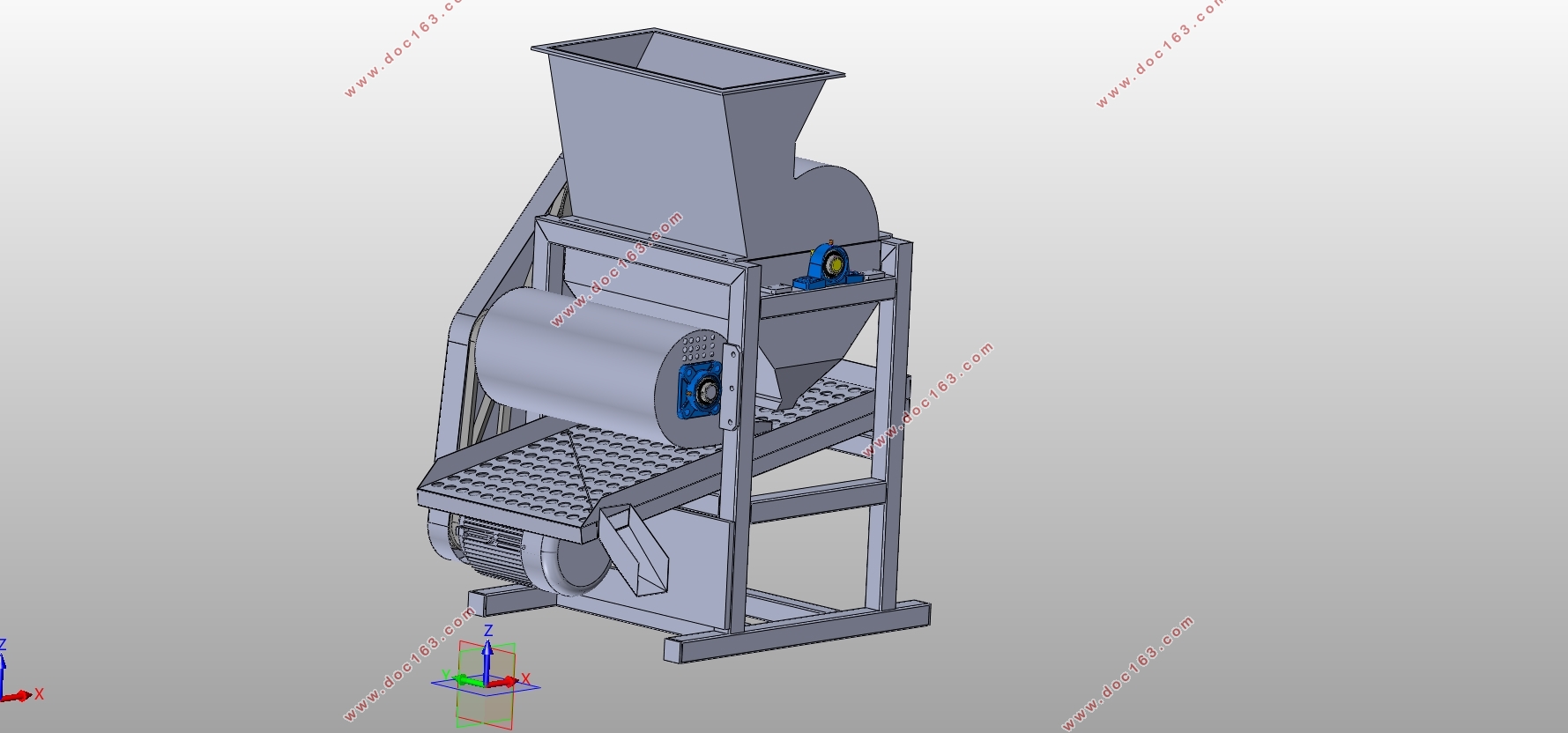

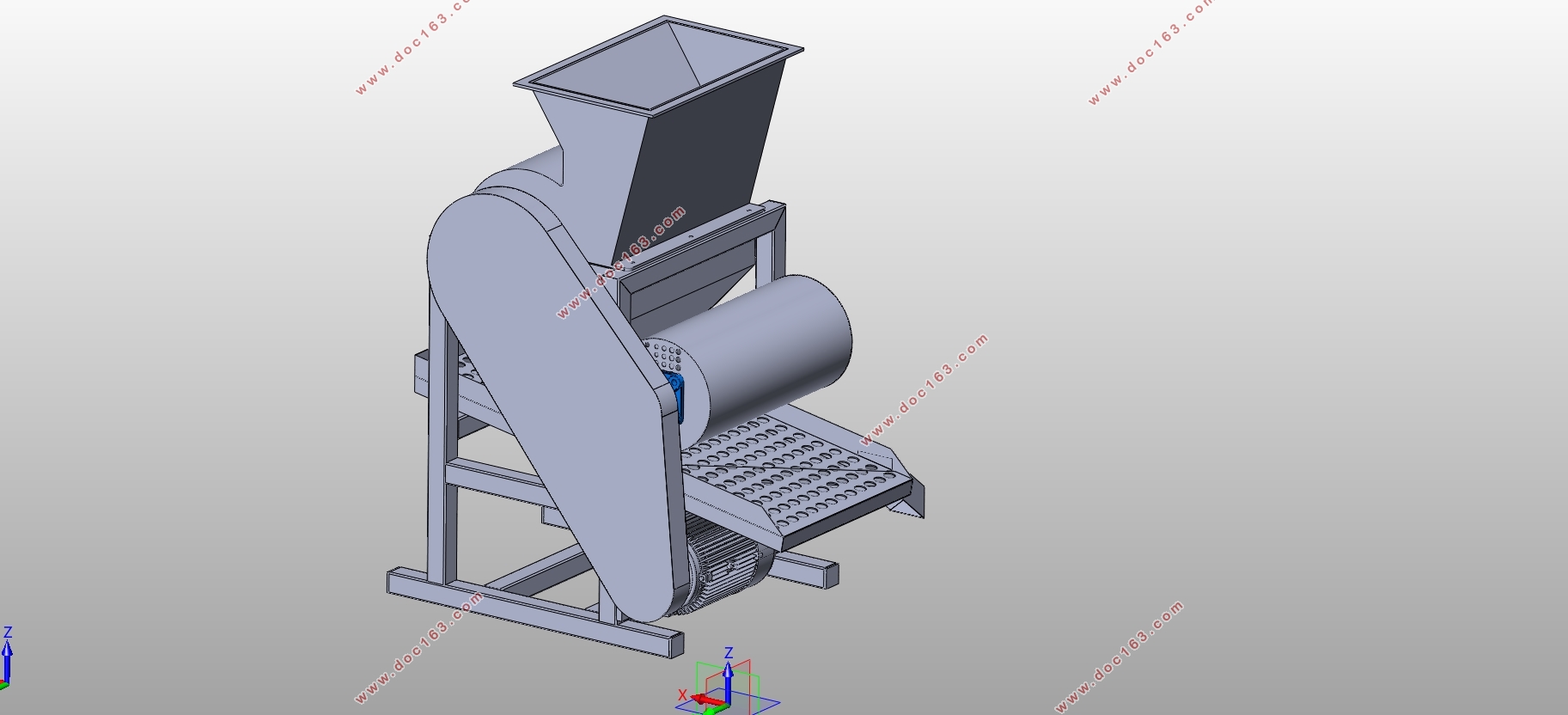

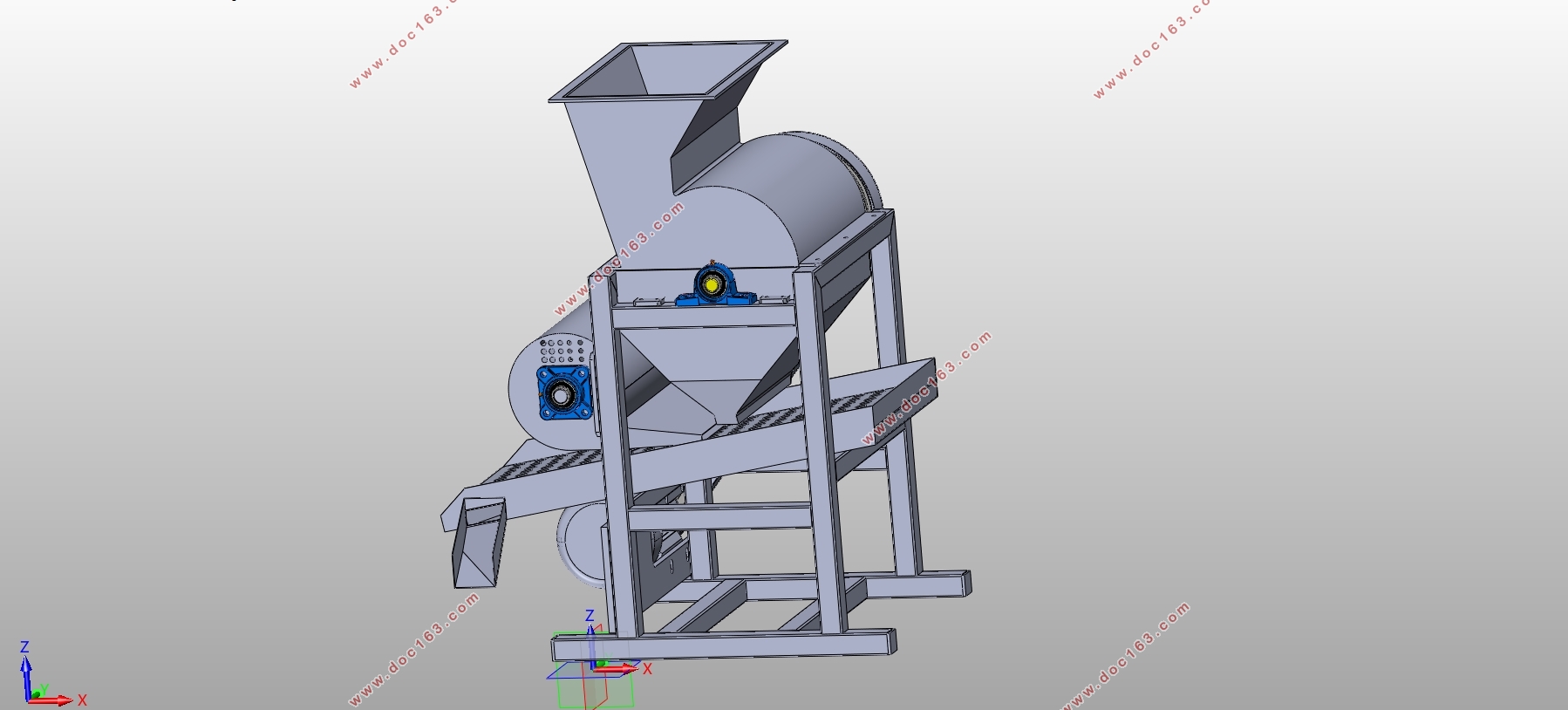

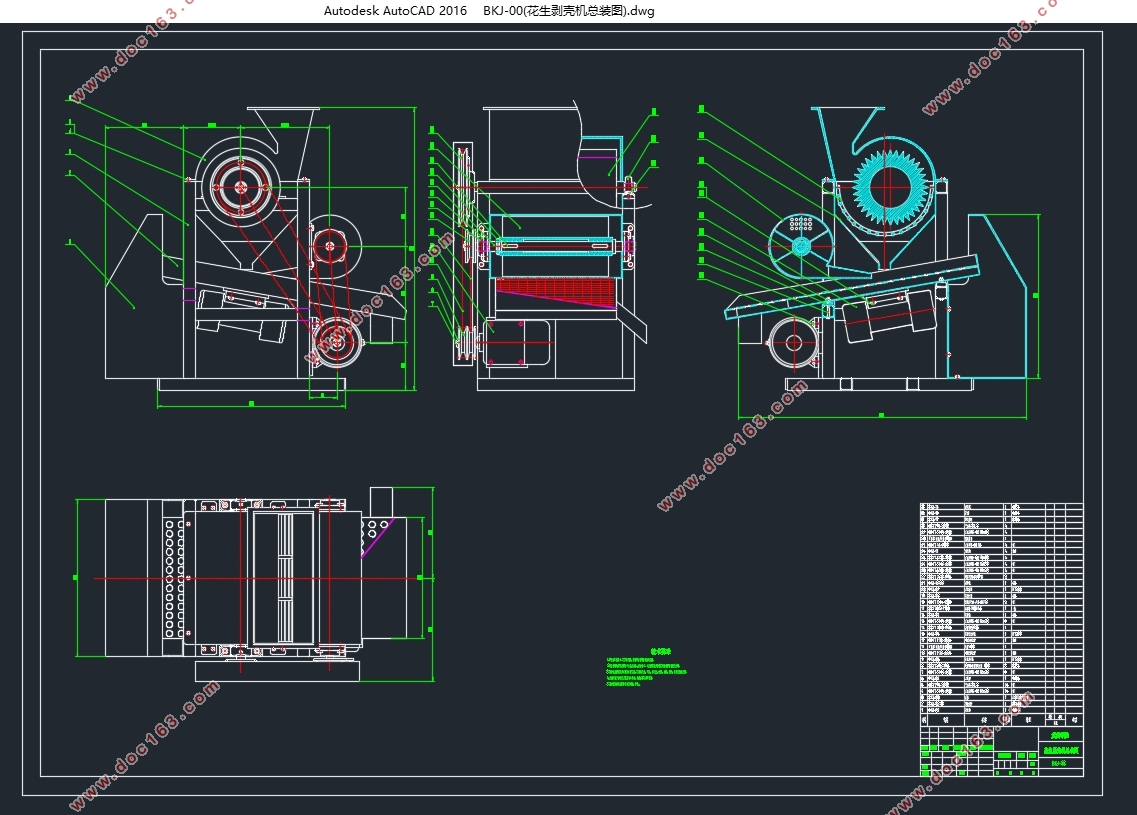

花生剥壳脱壳机结构设计(含CAD零件图装配图,SolidWorks三维图)

花生剥壳脱壳机结构设计(含CAD零件图装配图,SolidWorks三维图)(论文说明书9000字,CAD图4张,SolidWorks三维图,答辩PPT)

摘 要

花生是我国重要的农作物,经济价值高,是榨取花生油的原材料,花生外壳包裹着一层花生壳,采用人工剥壳效率低下、劳动成本高。花生脱壳机的出现很大程度解决了这个问题。通过查询相关文献。本课题设计的花生脱壳机采用滚筒式结构,花生在滚筒和半圆栅栏间受到打击和摩擦,花生壳被打碎,实现脱壳。并采用滚筒和半栅笼偏心的结构,可以对不同大小的花生来进行脱壳,其脱壳率高,分离装置可以将花生壳与花生进行分离。对所设计的机械零零部件进行校核;对机械部分零部件三维建模及装配;进行零部件及总装配图的二维CAD图纸绘制。

关键词:花生脱壳机;滚筒式结构;偏心;渐变结构;分离

Abstract

Peanut is an important crop in China with high economic value. It is the raw material for extracting peanut oil. The shell of peanut is wrapped with a layer of peanut shell.The peanut shucking machine designed in this project adopts the roller structure. The peanut is hit and rubbed between the roller and the semicircle fence, and the peanut shell is broken to realize the shucking. And the eccentric structure of roller and half grid cage can be used to dehulling peanuts of different sizes, which has a high rate of dehulling, and the device can be used to separate the peanut shell from the peanut. Checking the designed mechanical spare parts; 3d modeling and assembly of mechanical parts; 2 d CAD drawing of parts and assembly drawings

Key words:Peanut sheller; Drum structure; off-centre ;Gradient structure; separat

[资料来源:https://www.doc163.com]

[资料来源:http://www.doc163.com]

[资料来源:http://www.doc163.com]

目录

1 引言 1

1.1研究目的与意义 1

1.2国内外花生脱壳机研究现状和发展 2

1.3 目前花生脱壳机采用的脱壳原理 3

1.4 花生分离机构 6

1.5课题研究的内容 6

2.脱壳机构的比较与选择 7

2.1辊压式脱壳 7

2.2闭式纹杆花生脱壳 7

2.3脱壳方案的确定 7

2.4脱壳机构的改进 8

3.花生脱壳机的原理和方案设计 9

3.1花生脱壳机的原理 9

3.2花生脱壳机的方案设计 9

4.花生脱壳机主要部件的设计 11

4.1滚筒直径和转速的计算 11 [资料来源:www.doc163.com]

4.2脱壳机所需功率计算与电机选择 12

4.3滚筒传动设计与选择 13

4.4传动轴的设计 15

4.5传动轴的校核 17

4.6键连接强度 18

4.7轴承的校核 19

4.8风机传动的设计 19

5.花生脱壳机的各部件设计 22

5.1料斗的设计 22

5.2滚筒的设计和材料的选择 22

5.3半栅笼 23

5.4机架的设计 24

5.5筛分板的设计 25

5.6鼓风叶轮的设计 26

6结论与展望 28

6.1结论 28

6.2展望 28

谢辞 30

参考文献 31

上一篇:核桃脱壳机结构设计(含CAD零件图装配图,PROE三维图)