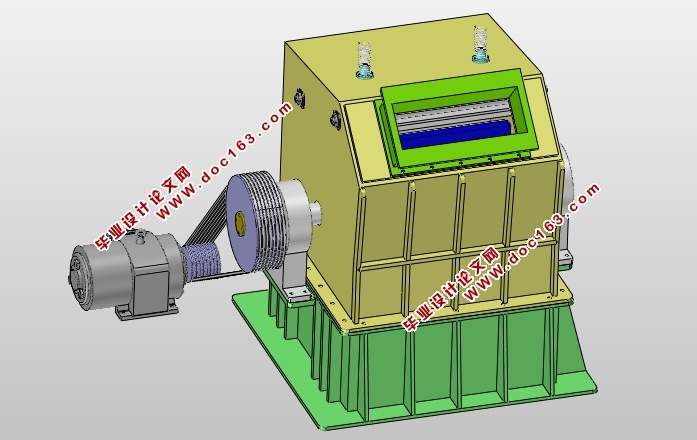

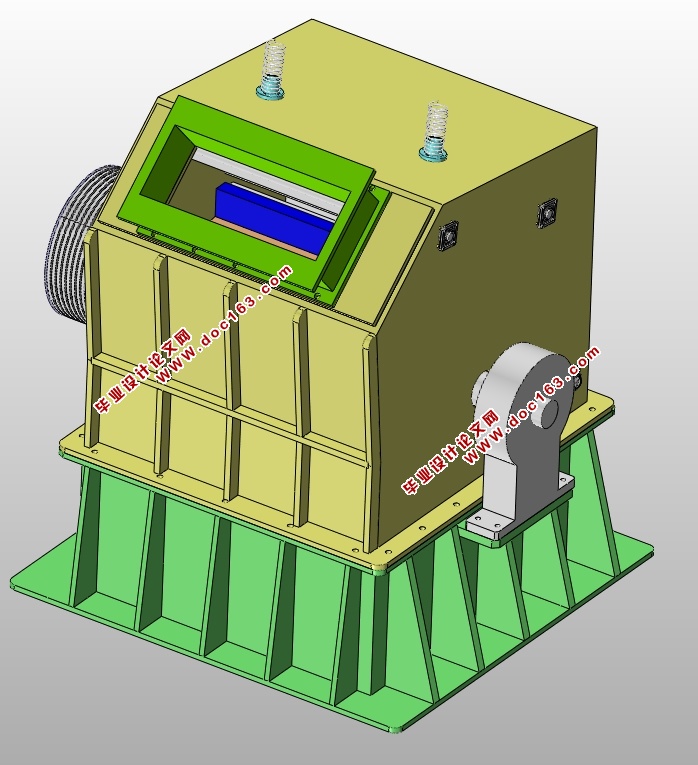

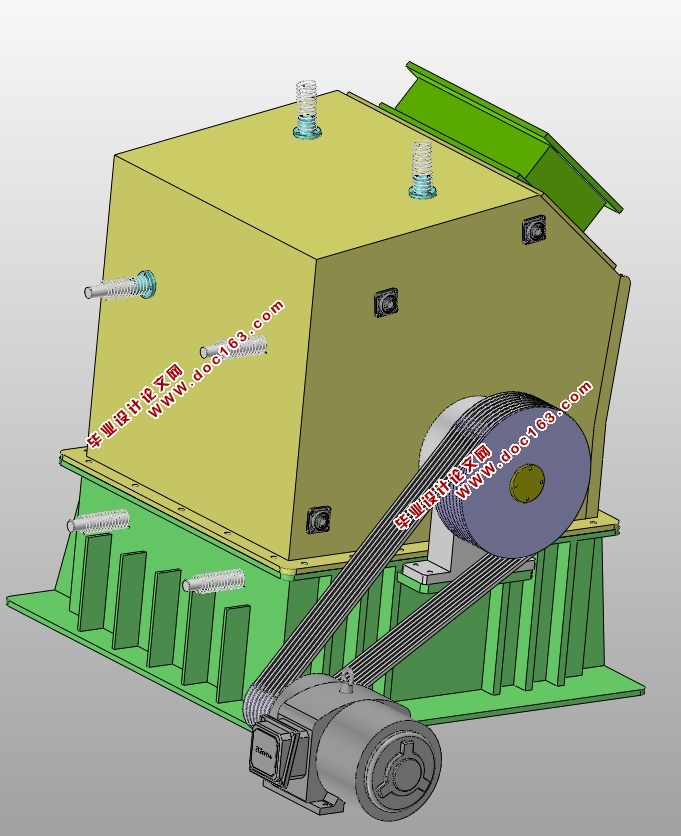

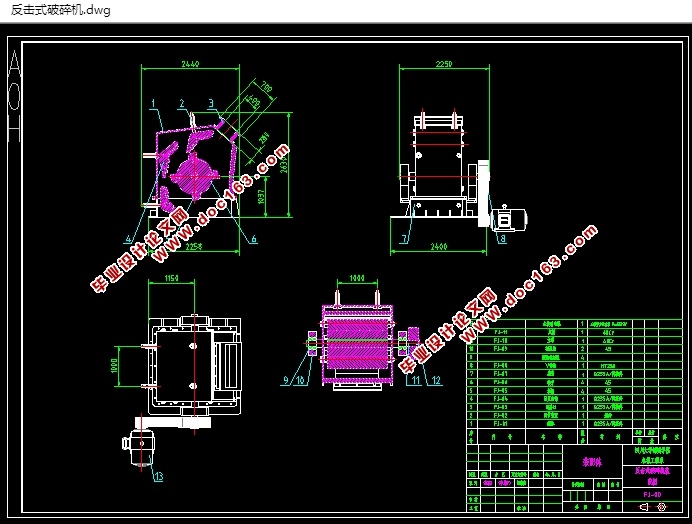

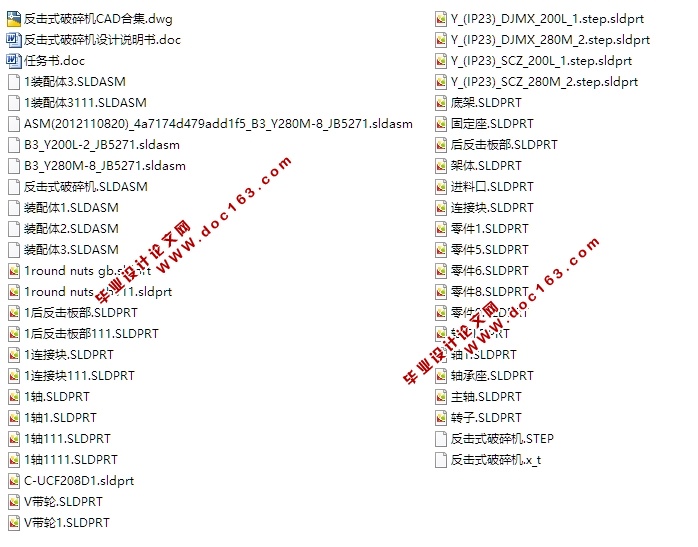

反击式破碎机的设计(含CAD零件装配图,STEP,x_t,SolidWorks三维图)

反击式破碎机的设计(含CAD零件装配图,STEP,x_t,SolidWorks三维图)(任务书,论文说明书13000字,CAD图纸12张,STEP,x_t,SolidWorks三维图)

摘 要

在国民经济建设中,水泥是不可或缺的基础原材料。作为重要的基础产业,水泥行业的发展程度成为一个国家社会发展水平和综合实力的重要衡量指标。我国经济正处于高速发展期,基础设施建设成为国内投资最主要的方式。因此,水泥作为最主要的原材料之一,必然也处于扩张阶段水泥生产过程中,大部分原料要进行粉碎,如石灰石、黏土、铁矿石、煤等。石灰石是生产水泥用量最大的原料,开采后的粒度较大,硬度较高,因此石灰石的破碎在水泥厂的物料破碎中占有比较重要的地位。

在新的市场需求的驱动下,矿山开采设备的更新和优化升级更加迫切。国内圆锥破碎机设备生产企业充分挖掘市场潜力,大力发展大型环保节能的圆锥破碎机械设备,在绿色环保化矿山开采的转变中挥积极作用。一般生产大型圆锥破碎机设备的企业对设备环保指数上都有严格的要求。各企业在生产设备时,都充分考虑到设备在运行中可能会出现的种种问题,从而减少设备因为振动或者操作不当而引起的噪音大、污染重等现象。

破碎过程要比粉磨过程经济方便,合理选择破碎设备非常重要,物料入磨前,尽可能将大物料破碎至均匀、细小的粒度,以减轻粉磨设备的负荷,提高磨机产量,同时也有利于物料的均匀化,提高配料的准确性。破碎机种类包括:颚式破碎机,反击式破碎机,冲击式破碎机、圆锥破碎机、锤式破碎机、旋回式破碎机、复合式破碎机等。反击式破碎机由转子,上盖,底座,后架四大部分组成,上盖既是破碎机的外壳,又是与内部结构相辅相成的组成部分,上盖内部的衬板对于石料破碎的粒度和破碎机的工作效率起到至关重要的作用。上盖的设计既要要求外形的美观又要具有实用性,一台机器外观设计过于花俏会造成加工工艺复杂、制造成本上升,过于臃肿,

会造成运输困难的同时也增加了制造的成本。我在设计过程中着眼于功能性,节约材料,机身轻便,外形大方几个方面,特别是制作材料的选取,选择的材料要兼具经济性和耐用性。

关键词:反击式破碎机;矿山开采;工作效率;外观

Abstract

In national economic construction, cement is the indispensable basis of raw materials. As an important basic industry, cement industry development has become a national and social development level and comprehensive strength is important measure index. The economy of our country is in the period of rapid development, infrastructure construction has become the main mode of domestic investment. Therefore, the cement as the main raw materialalso in the expansion phase.In the process of cement production, most of the raw material to be crushed, such as limestone, clay, iron ore, coal and other. Limestone is the productionof cement dosage is the biggest raw material, after mining of large size, high hardness, therefore limestone crusher in cement plant material crushing occupies a fairly important position. Crushing process than grinding process is economical and convenient, reasonable selection of crushing equipment is very important, the material into the grinding, as far as [资料来源:http://doc163.com]

possible the large crushing to uniform, fine granularity, so as to reduce the grinding equipment load, improve mill output, but also conducive to the material uniformity, high accuracy of batching. Categories include: crusher jaw crusher, impact crusher, impact crusher, cone crusher, hammer crusher, gyratory crusher, compound crusher etc.. Strike back type crushing machine is composed of a rotor, cover, a base, a rear rack four parts, the upper cover is broken machine shell, and is associated with the internal structure of complement

component, the inside of the upper cover of the lining board for stone crushing granularity and the crusher work efficiency plays an important role in. Cover design not only to request the appearance and practicability, a machine design too fancy will cause complex processing technology, manufacturing cost rises, bloated, will cause the transportation difficulty also increases the cost of manufacture. I am in the design process, focusing on the functional, material saving, light body, generous appearance aspects, especially in making the selection of materials, materials selected to both economy and durability.

[来源:http://www.doc163.com]

Key words: cement, limestone, strike back type crushing machine,the upper cover

反击式破碎机的工作原理

反击式破碎机利用高速旋转的转子上的板锤,对送入破碎腔内的物料产生高速冲击而破碎,且使已破碎的物料沿切线方向以高速抛向破碎腔另一端的后反击部,再次被破碎,然后又从后反击部反弹到板锤,继续重复上述过程。在往返途中,物料间还有互相碰击作用。由于物料受到板锤的打击、与后反击部的冲击以及物料相互之间的碰撞,物料不断产生裂缝,松散而致粉碎。当物料粒度小于后反击部与板锤之间的缝隙时,就被卸出。下图为PF-1010的反击式破碎机工作原理图。

反击式破碎机破碎物料时,物料悬空受到板锤的冲击。如果物料粒度较小,冲击力近似通过颗粒的重心,物料将沿切线方向抛出。如果物料粒度较大,则物料抛出时产生旋转,抛出的方向与切线方向成X角度,为了使料块能深入板锤作用圈D之内,减少旋转,给料滑板的下部向下弯曲,见上图。

物料的主要破碎过程是在转子的上部进行的,见上图。物料受到第一次冲击后,在机内反复地来回抛掷。此时,物料由于局部的破坏和扭转,已不按预是轨迹作有规则的运动,而是在转子上部不同位置反复冲击,而后物料进入下部

区,进一步冲击粉碎。反击面2及3与转子间构成的缝隙大小,对产品粒度组成具有一定的影响。破碎腔的增多对产品粒度均匀及减少大颗粒起作用,但电耗增加,生产能力下降。通常作为粗碎用的反击式破碎机,具有1-2个破碎腔;

用于细碎的反击式破碎机,具有2-3个甚至更多一些的破碎腔。

由以上所述反击式破碎机的破碎作用,主要由三种形式对物料进行破碎,在转子的上部是自由破碎和反弹破碎,而在中部区域主要是铣削破碎。

以上是单转子反击式破碎机的工作原理,双转子破碎机的工作原理是一致的,只是双转子反击式破碎机对物料的破碎过程更缴烈。双转子反击式破碎机内有两个平行安装的转子,两转子由单独的电机带动作相向旋转对(也有同相旋转的)物料进行破碎。反击式破碎机对物料的破碎过程见下图。

反击式破碎机按其结构特征可分为单转子反击式破碎机和双转子反击式破碎机。按转子转向,单转子反击式破碎机分可逆式转动和不可逆式转动两大类型。双转子反击式破碎机可分为同向转动式、反向转动式和相向转动式三种类型。

[资料来源:https://www.doc163.com]

目录

摘要 2

Abstract 2

第一章 绪论 3

1.1反击式破碎机的发展概况.............................................................................................4

1.2反击式破碎机的应用.......................................................................................................4

1.3各种反击式破碎机的特点.............................................................................................4 [资料来源:Doc163.com]

1.4反击式破碎机的发展方向.............................................................................................5

1.5反击式破碎机的优缺点..................................................................................................5

1.5.1反击式破碎机的优点...............................................................................................6

1.5.2反击式破碎机的缺点................................................................................................7

第二章 反击式破碎机的总体方案及结构设计..........................................................8

2.1反击式破碎机的工作原理 ..9

2.2反击式破碎机的结构和布置形式 9

2.2.1反击式破碎机的结构.................................................................................10

2.2.2反击式破碎机的布置方式.........................................................................10 [资料来源:Doc163.com]

2.2.3破碎的目的和意义........................................................................................11

2.2.3.1破碎的目的..........................................................................................12

2.2.3.2破碎的意义..........................................................................................13

第三章 反击式破碎机的设计计算.............................................................................13

3.1转子转速的计算................................................................................................14

3.2生产率的计算......................................................................................................15

3.3主电动机的选择及传动比的分配..................................................................16

3.3.1电动机的选择..............................................................................................16

3.3.2传动比的分配..............................................................................................17

3.4主轴的设计计算................................................................................................17

3.4.1主轴的设计...................................................................................................18

3.4.2主轴的校核..................................................................................................19

3.5.V带传动的设计计算........................................................................................19

3.5.1设计功率 ...............................................................................19

3.5.2选定带型..................................................................................19

3.5.3传动比......................................................................................20

3.5.4小带轮基准直径........................................................................20

3.5.5大带轮基准直径........................................................................21

3.5.6 带速验算.................................................................................22

3.5.7 初定轴间距..............................................................................22

3.5.8 所需带的基准长度...................................................................23

3.5.9 实际轴间距..............................................................................24

3.5.10 小带轮包角............................................................................26

3.5.11单根V带的基本额定功率.........................................................27

3.5.12 时单根V带型额定功率增量..............................................27

3.5.13 V带的根数..............................................................................27

3.5.14 单根V带的预紧力..................................................................28

3.5.15作用在轴上的力......................................................................28

3.5.16带轮的结构和尺寸...................................................................28

3.6后反击部的设计...........................................................................29

第四章各主要零件强度的校核计算....................................................................................31

4.1滚动轴承的校核及寿命计算............................................................................32

4.2键联接的设计与校核............................................................................................33

4.2.1键的选择............................................................................................................34

4.2.2键的校核.............................................................................................................35

致谢 40

参考文献 41 [资料来源:http://www.doc163.com]

上一篇:电梯缓冲器落锤实验装置的设计(含CAD零件装配图,SolidWorks三维图)

下一篇:糕点切片机机芯结构的设计(含CAD零件装配图,x_t三维图)