红薯分级分选机的设计(含CAD零件图和装配图)

红薯分级分选机的设计(含CAD零件图和装配图)(选题审批表,任务书,开题报告,中期检查表,论文说明书17000字,CAD图6张)

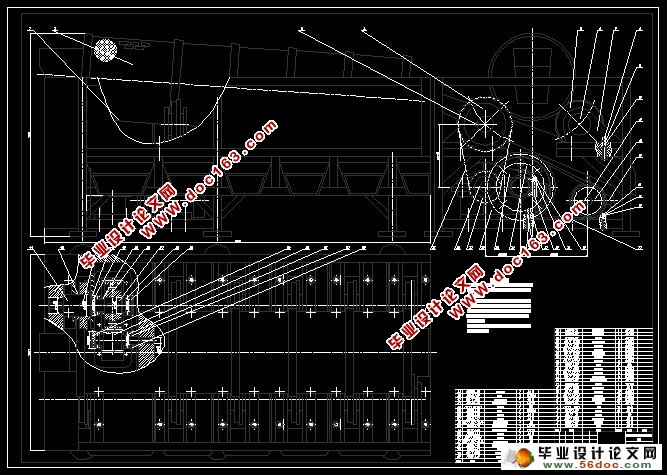

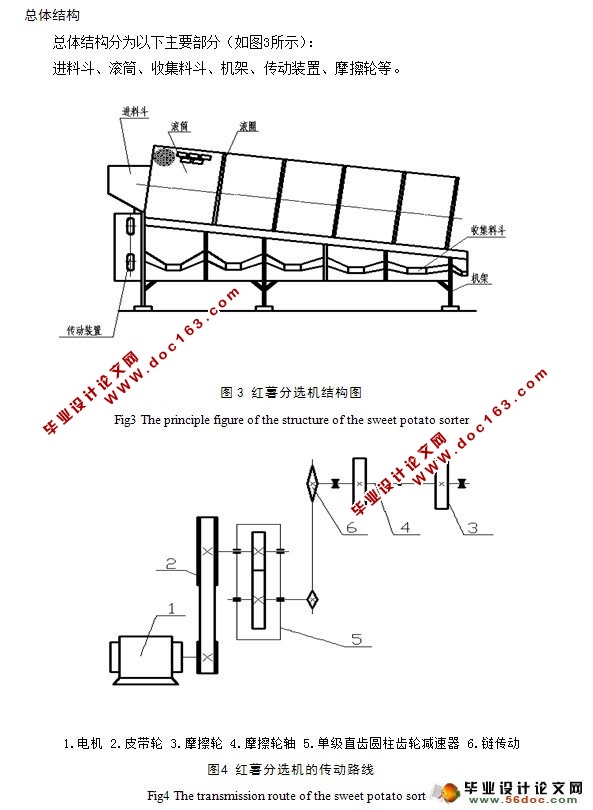

摘 要:本文分析了中国国内外红薯分级分选机的研究和发展现状,对未来进行了展望,设计出了一种新型红薯分级分选机构。该红薯分级分选机是由分级滚筒、传动机构和电动机组成。采用电动机提供动力,通过带轮传动机构,将运动和动力传送到直齿圆柱齿轮减速器,然后再通过链轮传动机构,将所需的运动和动力传送至分级滚筒上,从而实现红薯的分选。整个机构简单且易于操作,便于维护,提高了生产效率,降低了劳动强度,为实现红薯加工机械化与规模化提供了前提。

关键词:红薯;形状;分级机构;分级滚筒;

The design of sweet potato sorting machine

Abstract: This paper analyzes the present situation of the Chinese domestic and foreign sweet potato sorting machine research and development, on the future prospects, we design a new type of sweet potato sorting mechanism. The sweet potato sorting machine is composed of grading cylinder, transmission mechanism and a motor. The power provided by a motor, through a belt pulley transmission mechanism, the movement and power is transmitted to the straight tooth cylindrical gear reducer, and then through the chain wheel transmission mechanism, the required movement and power is transmitted to the classification on the drum, thereby we can realize the separation of sweet potato. The entire mechanism is simple and easy to operate, easy to maintain, improve production efficiency, reduce labor intensity, which help to achieve the sweet potato processing mechanization and scale and to provide the premise.

Key Words: sweet potato; shape; the grading mechanism; grading cylinder

[来源:http://www.doc163.com]

目 录

摘要…………………………………………………………………………………………1 [资料来源:Doc163.com]

关键词………………………………………………………………………………………1

1 前言………………………………………………………………………………………2

2 总体方案的拟定…………………………………………………………………………3

2.1 原理分析…………………………………………………………………………3 [来源:http://www.doc163.com]

2.2 总体结构设计……………………………………………………………………5

2.3 各执行机构主要参数的计算…………………………………………………6

2.4 传动装置的运动和动力参数的计算…………………………………………13

3 主要零件的选择和设计………………………………………………………………15

3.1 皮带传动的设计计算…………………………………………………………15 [资料来源:http://doc163.com]

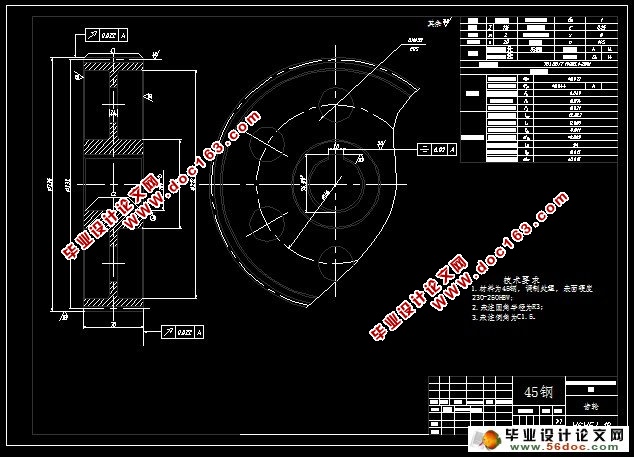

3.2 直齿圆柱齿轮的设计计算……………………………………………………17

3.3 滚子链传动的设计计算………………………………………………………20

3.4 轴的设计计算…………………………………………………………………21

3.4.1 高速轴的设计计算……………………………………………………21

3.4.2 低速轴的设计计算……………………………………………………24

3.5 轴承的校核……………………………………………………………………27

3.6 键的设计计算与校核…………………………………………………………27

3.7 润滑与密封……………………………………………………………………28

3.8 主要缺点和有待进一步改进的地方…………………………………………29

4 结束语…………………………………………………………………………………29 [资料来源:https://www.doc163.com]

参考文献………………………………………………………………………………30

致谢……………………………………………………………………………………31

附录……………………………………………………………………………………32

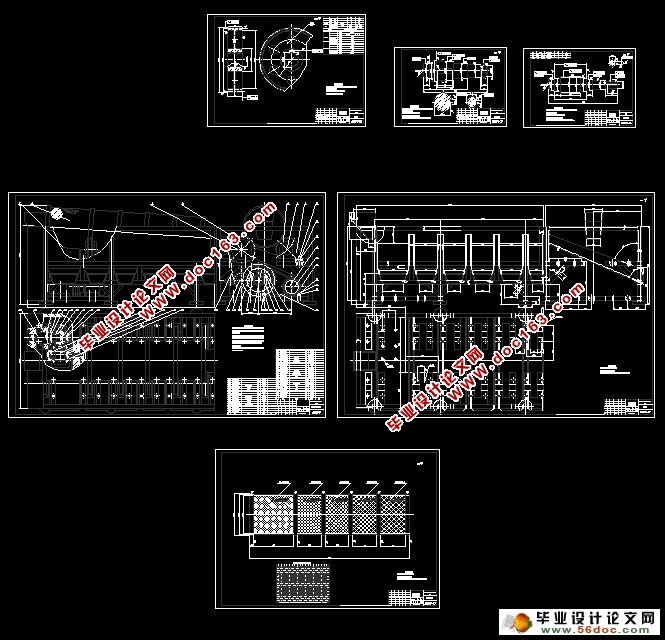

附录1:装配图

附录2:机架零件图

附录3:分机滚筒零件图

附录4:齿轮零件图

附录5:齿轮轴零件图

附录6:低速轴零件图

[资料来源:http://doc163.com]

上一篇:混凝土搅拌站输送系统和搅拌系统设计(含CAD零件图和装配图)