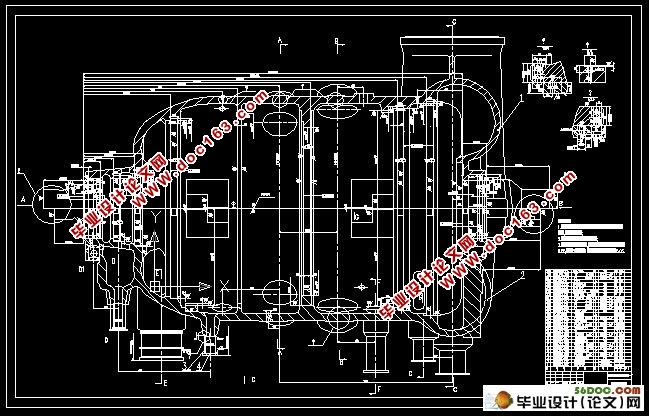

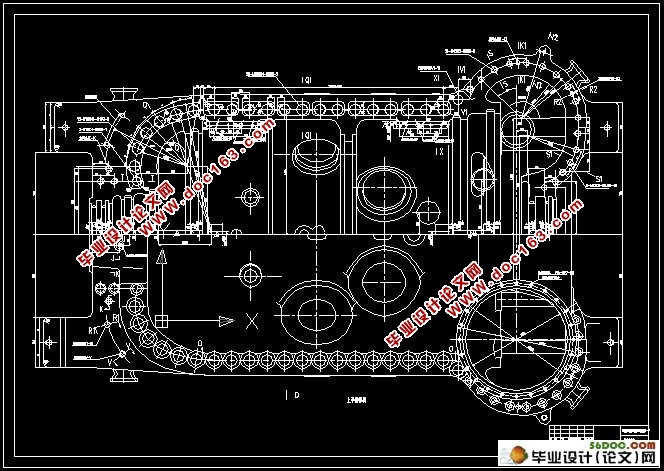

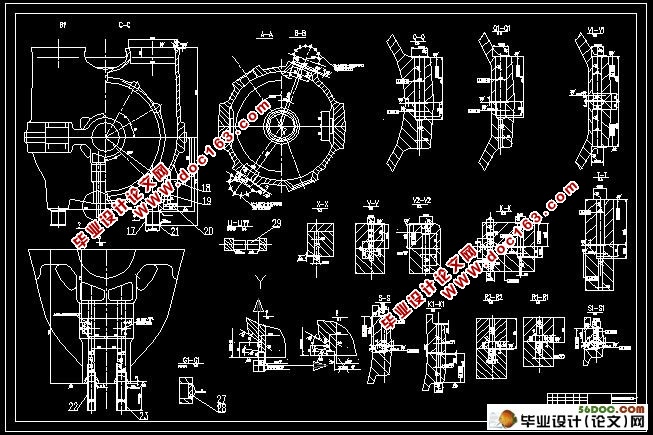

高中压外缸设计

高中压外缸设计(CAD图纸5张,设计说明书18000字)

摘 要

针对汽轮机的高中压外缸加工的问题,在分析其结构特点的基础上,应采用加工中心加工,这样能提高加工精度,一致性好,而且大大提高了生产率,从而降低了加工成本。

由于普通机床受控于操作工人,因此,在普通机床上用的只是一个工艺过程卡,机床的工切削用量、走刀路线、工序的工步等往往都是操作工人自行选定的。数控加工的程序是数控机床的指令性文件。加工中心受控于程序指令,加工的全过程都是按程序指令自动进给的。因此,数控加工程序与普通机床工艺规程有较大差别,涉及的内容也较广。数控机床加工程序不仅要包括零件的工艺过程,而且还要包括切削用量,走刀路线,刀具尺寸以及机床的运动过程,程序的好坏不仅会影响机床效率的发挥,而且将直接影响到零件的加工质量。

关键字:数控编程,走刀路线,指令。

Abstract

Outside the abstract presses the question in view of the steam turbine high school which the cylinder processes, in analyzes its unique feature in the foundation, should use the processing center processing, like this can increase the processing precision, the uniformity is good, moreover greatly enhanced the productivity, thus reduced the processing cost.

Because the ordinary engine bed is controlled to the operation worker, therefore, uses on the ordinary engine bed is only a technological process card, the engine bed labor cutting specifications, move tool the route, the working procedure labor step and so on often all is operates the worker voluntarily to designate. The numerical control processing procedure is the numerical control engine bed instructional document. The processing center is controlled to the program directive, the processing entire process all is automatically enters according to the program directive for. Therefore, the numerical control processing procedure and the ordinary engine bed technological process have comparatively wide difference, involves the content is also broader. The numerical control engine bed processing procedure not only must include the components the technological process, moreover also must include the cutting specifications, move tool the route, the cutting tool size as well as the engine bed rate process, the procedure quality not only can affect the engine bed efficiency the display, moreover directly will affect the components processing quality.

KEY WORDS: Numerical control programming, move tool route, instruction.

[资料来源:http://doc163.com]

目 录

摘要 ……………………………………………………………… Ⅰ

Abstract ………………………………………………………… Ⅱ [来源:http://www.doc163.com]

第1章 绪论 ……………………………………………………… 1

1.1 数控机床的产生 …………………………………… 1

1.2 数控编程的定义 …………………………………… 1

第2章 数控编程常用指令及格式 ………………………… 3

2.1 数控编程的步骤 ………………………………… 3

2.2 数控编程的方法 …………………………………… 5

2.3 数控编程常用指令及其格式 ……………………… 7

2.3.1 准备功能指令 …………………………… 9

2.3.2 辅助功能指令 …………………………… 12

2.3.3其它常用功能指令 ……………………… 13

第3章 高中压外缸程序编制 …………………………… 15

3.1 半粗加工 …………………………………………17

3.1.1上半程序 …………………………………… 17

3.1.2子程序 ……………………………………… 19 [来源:http://Doc163.com]

3.1.3下半程序 ………………………………… 23

3.2精加工 ………………………………………… 27

3.2.1上半程序 …………………………………… 28

3.2.1子程序 ……………………………………… 34

3.2.3下半程序 …………………………………… 38

结论 ………………………………………………………………… 45

[资料来源:http://www.doc163.com]

致谢 ………………………………………………………………… 46

参考文献 …………………………………………………………… 47

附录1 ……………………………………………………………… 48

附录2 ……………………………………………………………… 52

[资料来源:http://www.doc163.com]

上一篇:二级减速器三维设计(PROE)

下一篇:板材送进夹钳装置的设计