搅拌机的设计(含cad零件图和装配图)

搅拌机的设计(含cad零件图和装配图)(含开题报告,毕业论文15000字,中期检查表,CAD图纸6张)

摘 要

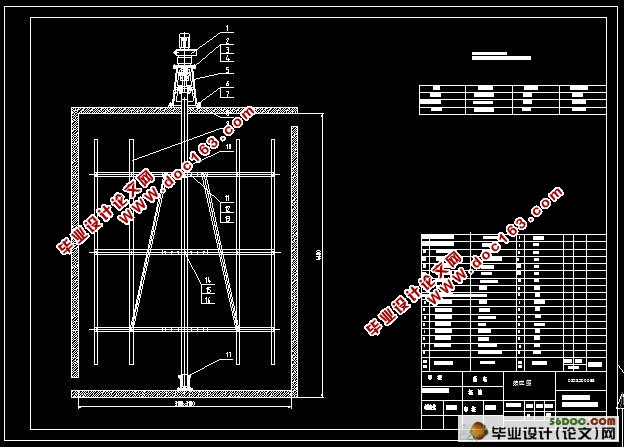

搅拌机是搅拌设备的心脏。在搅拌机设计及使用过程中,合理的选取搅拌机的结构,运动和工作参数,直接关系到搅拌质量和搅拌效率。完成絮凝过程的絮凝池在净水处理中占有重要的地位。天然水中的悬浮物质及肢体物质的粒径非常细小。为去除这些物质通常借助于混凝的手段,也就是说在原水中加入适当的混凝剂,经过充分混和,使胶体稳定性被破坏(脱稳)并与混凝剂水介后的聚合物相吸附,使颗粒具有絮凝性能。而絮凝池的目的就是创造合适的水力条件使这种具有絮凝性能的颗粒在相互接触中聚集,以形成较大的絮凝体(絮粒)。因此,絮凝池设计是否确当,关系到絮凝的效果,而絮凝的效果又直接影响后续处理的沉淀效果。絮凝搅拌机是絮凝池机械搅拌的装置,它主要用于废水处理的搅拌过程。本设计提到了絮凝池的设计,搅拌机的设计以及其工艺流程。

关键词: 絮凝池 混凝剂 沉淀效果 絮凝性能

Abstract

The mixer is the heart of the mixing equipment. A reasonable selection of the structure, movement and operating parameters of the mixer in the process of designing and using mixer, directly related to the quality and efficiency of the mixing. Flocculation pool which complete flocculation process occupies an important position in water treatment. The particle size of suspended substances and physical substances of natural water is very small. Means for the removal of these substances is usually by means of coagulation, which means that adding an appropriate coagulant in the raw water. After sufficient mixing, the colloidal stability is destroyed (destabilization) and the raw water is adsorpted with the polymer of coagulant water mediated to make particles have flocculation properties. While The purpose of flocculation tank is to create suitable hydraulic conditions to have these particles which have flocculation properties aggregated in contact with each other to form larger flocs (floc particles). Therefore, the design of flocculation tank is related to the effect of flocculation and the effect of flocculation directly impact on the effect of subsequent processing of the sedimentation. Mixer of flocculation is a device of mechanical agitation of the flocculator and it is mainly used for the mixing process of wastewater treatment. This design referred to the flocculator design, mixer design and its technical process. [资料来源:http://Doc163.com]

Key words: Flocculator Coagulant Sedimentation effect Flocculation performance

本课题的设计思路

(1)絮凝池的结构尺寸的确定;

(2)搅拌机大小的确定及转速和功率的计算;

(3)由搅拌机功率来做电机的选型设计;

(4)由电机的型号尺寸来做联轴器的选型设计;

(5)由联轴器的型号尺寸来决定轴径以及对所决定的轴径进行计算验证;

(6)由轴径来做轴承的选型;

(7)由轴承的尺寸来做机座及支撑座的选型设计。

[资料来源:http://doc163.com]

目 录

前 言 1

1 搅拌机的构造与原理 2

1.1 搅拌机的发展概述 2

1.2反应搅拌机的工作原理 2

1.3 絮凝的工作原理 3

1.4 水处理中的搅拌设备 4

1.5 絮凝搅拌机的适应条件和构造 4 [资料来源:http://doc163.com]

1.5.1 絮凝搅拌机的适应条件 4

1.5.2 絮凝搅拌机的构造 5

1.6本课题的设计思路 8

2 絮凝池的设计 9

2.1絮凝池的设计探讨 9

2.1.1 絮凝的相似关系 11

2.1.2 假设和设想 15

2.2絮凝池的设计要求及结果 21

3 絮凝搅拌机的设计 23

3.1设计原始数据 23

3.2设计要点 23

3.3设计计算数据 23

3.4桨叶的设计 24

3.4.1桨叶结构尺寸确定 24

3.4.2搅拌器转速计算 25

3.4.3搅拌功率计算 27

4 电动机及减速器的选型 28

4.1减速器和电动机的选型条件 28

4.2电动机与减速器的选择 29

4.3联轴器的选型 31

4.4搅拌轴的设计及其结果验证 31

4.5轴与桨叶、联轴器的连接 32

4.5.1连接形式 32

4.5.2联轴器与轴的连接 33

4.6轴承的选型及轴的最终确定 33

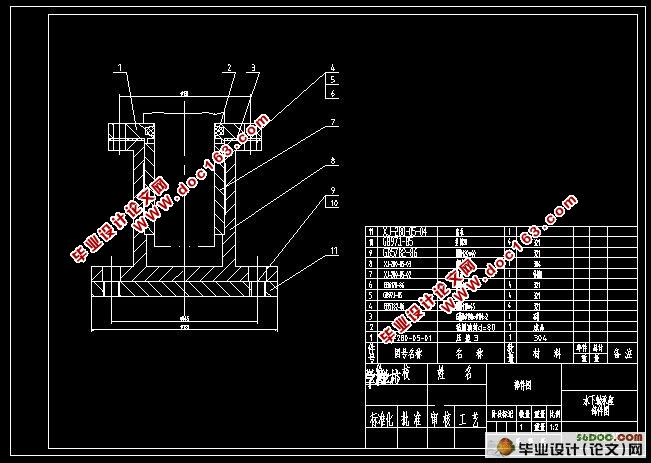

5 支撑装置设计 34

5.1搅拌机的支承部分 34

5.1.1机座 34

5.1.2轴承装置 35

5.2水下支撑座的设计 35

5.2.1轴承的选型 35

5.2.2支撑套的设计 36

6 轴的密封 38

6.1密封装置的类型 38

6.2 轴的密封选择 38

7 总结 40

符号说明 41

致 谢 42

参考文献 43

[资料来源:http://Doc163.com]

上一篇:内啮合多轴钻床设计

下一篇:250*400复摆式颚式破碎机