瓦楞纸板自动分料机的设计与开发(含CAD零件图装配图)

瓦楞纸板自动分料机的设计与开发(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书14000字,CAD图8张)

摘要

目前,瓦楞纸板的生产主要依靠工人进行分料,这种分料方式对工人来说劳动强度较大,而且分料效率较低,成本较高,存在一系列的问题。瓦楞纸板的自动分料需求日益高涨。经过本文的研究,我们设计开发了瓦楞纸板自动分料机,满足对瓦楞纸板分料的要求,并能够解决工人劳动强度大,生产效率低、生产成本高等一系列问题。

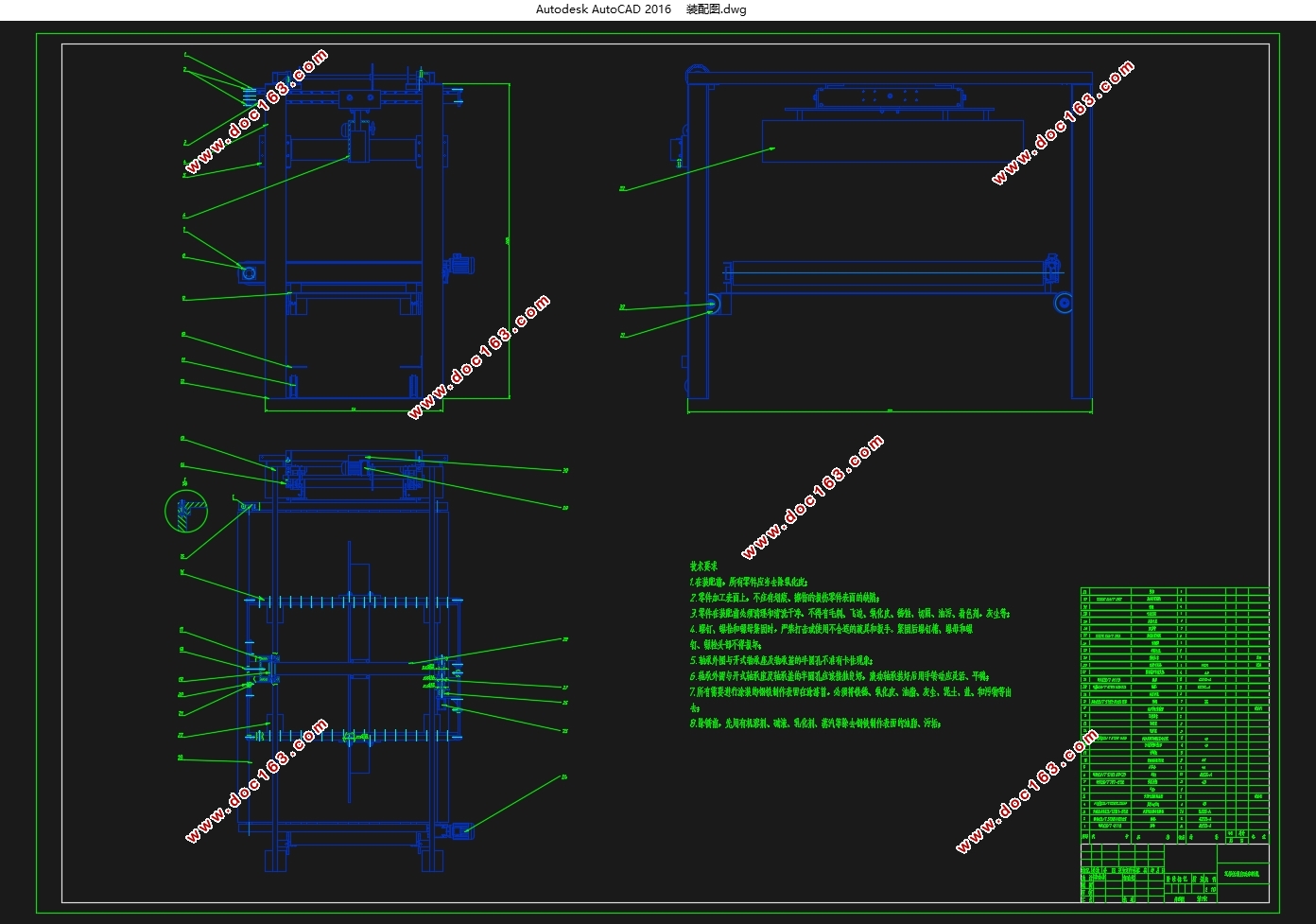

文章首先通过对瓦楞纸板历史的简单回顾,提出了研究的主要内容,即瓦楞纸板分料机的研究与设计。接着,对国内外相关理论发展以及瓦楞纸板自动分料机的实际运用情况进行探讨,从而得知瓦楞纸板自动分料机在实践中的应用,同时也知道了在国内目前并没有成熟的有关瓦楞纸板自动分料机的生产实践或文献资料。然后对可能在瓦楞纸板自动分料机上使用到的相关模块进行探讨,如升降机模块,推板模块,输送带模块等。接着,根据探讨的内容,进行细节方面的最佳方案选取。在进行方案设计的同时,根据已经选定的方案,在solidworks中画出瓦楞纸板自动分料机的三维图,详细的对瓦楞纸板自动分料机进行设计与开发,设计具体的机械结构,对其中不合适的部分进行改正,完成最终的三维图。然后对装配体中的重要结构件,承重结构件等进行强度校核,确定具体的尺寸,或者选定具体的型号,如推板部分同步带的相关计算,升降机链条部分的相关计算,承受推板部分的梁的强度计算,选定具体的型钢型号等。

[资料来源:https://www.doc163.com]

经过本文的研究,我们开发研究了能够代替人工完成瓦楞纸板分料工作的自动分料机,满足了瓦楞纸板生产所需的高效率、低成本等问题的要求。

关键词:瓦楞纸板;分料;瓦楞

Abstract

At present, the production of corrugated cardboard mainly relies on workers to sub-material, this way of distribution for workers, labor intensity is greater, and the material efficiency is low, high cost, there are a series of problems. Corrugated cardboard automatic demand for materials is growing. After the study of this paper, we designed and developed a corrugated cardboard automatic feeder, to meet the requirements of corrugated board material, and to solve the workers labor intensity, low production efficiency, high cost of production and a series of problems.

First of all, through the simple review of the history of corrugated cardboard, the main contents of the research are put forward, namely, research and design of corrugated cardboard sub-machine. Then, the development of the relevant theory at home and abroad and the actual use of corrugated cardboard automatic feeder to explore the corrugated cardboard automatic feeder in the practice of the application, but also know that there is no mature in the domestic corrugated Automatic production of cardboard automatic distributor or literature. And then on the corrugated cardboard automatic feeder can be used in the relevant modules to explore, such as the lift module, push plate module, conveyor belt module. Then, according to the content of the discussion, the details of the best program selection, such as the push plate part of the drive motor should be used servo motor or stepper motor, motor and timing belt coupling choice.Then, according to the already selected program, in the solidworks drawn corrugated cardboard automatic feeder of the three-dimensional map, the detailed design of corrugated cardboard automatic feeder design, design specific mechanical structure, which is not suitable part to correct, to complete the final three-dimensional map.And then the assembly of the important structural parts, bearing structure and other strength check to determine the specific size, or select the specific model, such as the push plate part of the relative calculation of the belt, the elevator chain part of the relevant calculation, Plate part of the beam strength calculation, select the specific type of steel and so on.

After the study of this paper, we have developed and studied the automatic dispenser which can replace the manual work of corrugated board to meet the requirements of high efficiency and low cost of corrugated board production.

Key word:Corrugated cardboard;Dosing;Corrugated board production line

根据设计任务书所给出的要求,瓦楞纸板自动粉料机的设计目标归纳如下:

(一) 设计出升降台的整体结构,使其在数值方向的位移量为1.8m,运动过程中的精度达到0.5mm,载重量为2t,并且选用合适的驱动部件;

(二) 合理的设计退半步分呢的结构,并选择合适的驱动不见,使得推力大小达到2000N,推动行程达到1.3m;

(三) 升降部分及推板部分的控制,通过相应的控制,使得整个运动机构实现预定的动作顺序,保证相应的精度。

[资料来源:http://www.doc163.com]

目录

摘要 I

[来源:http://www.doc163.com]

Abstract Ⅱ

目录 Ⅲ

第1章 绪论 1

1.1 背景及意义 1

1.2 瓦楞纸板分料的现状及发展趋势 1

1.2.1 瓦楞纸板分料的现状 1

1.2.2 瓦楞纸板分料的发展趋势 2

1.3 研究内容 3

1.3.1 升降系统 3

1.3.2 基于PLC控制的分料机构 3

第2章 总体方案设计 5

2.1 瓦楞纸板自动分料机简介 5

2.2 瓦楞纸板自动分料机的技术要求 5

2.3 瓦楞纸板自动分料机的方案设计与分析 6

2.3.1 瓦楞纸板自动分料机总体布局方案 6

2.3.2 电机的选取 7

2.3.3 输送带的选取 8

2.3.4 升降机构的设计 10

第3章 关键零部件的校核 14

3.1 同步带的校核 14

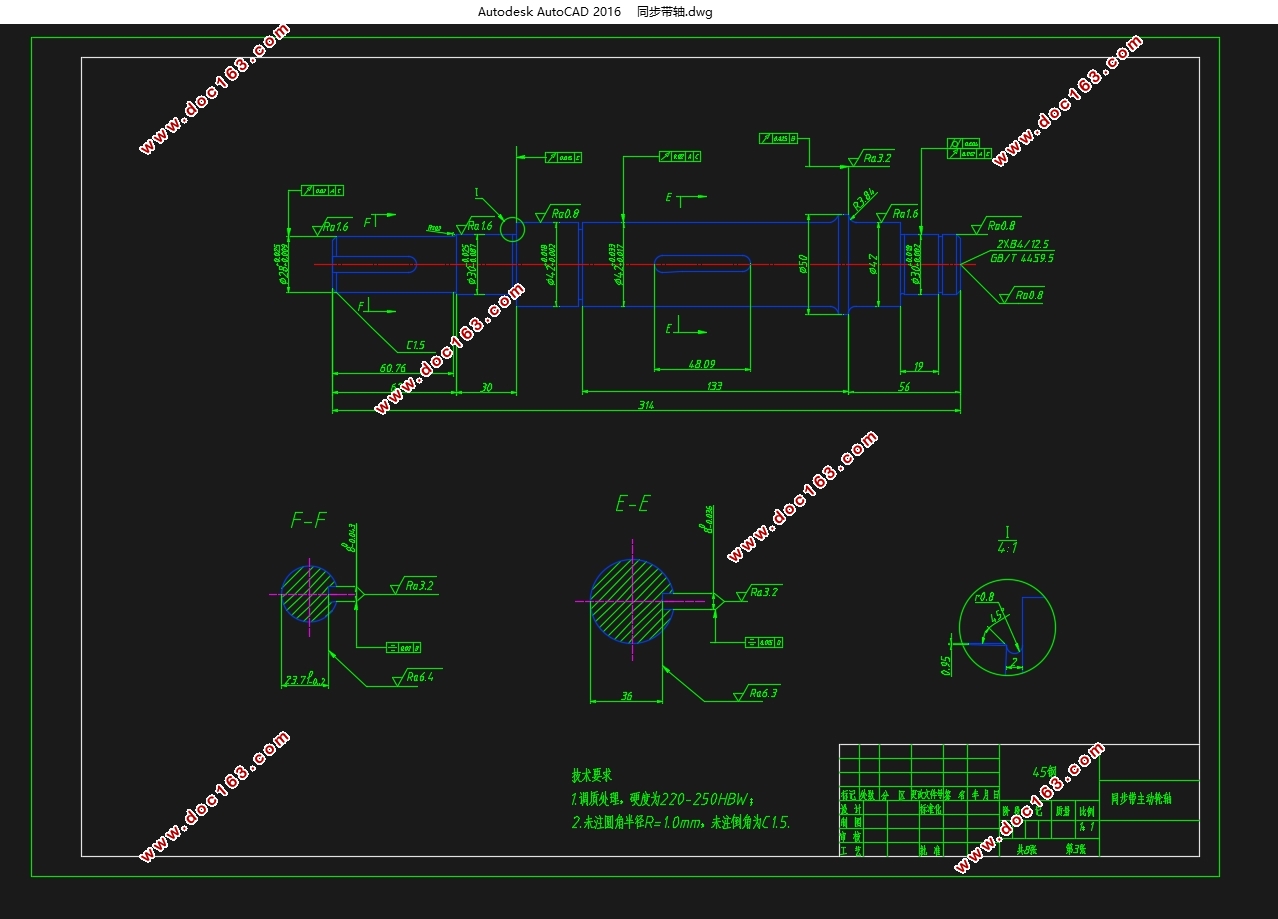

3.2 同步带轮轴的设计及其强度校核 18

3.2.1 同步带轮轴的设计 18

3.2.2 同步带轮轴的强度校核 21

3.3 升降系统滚子链传动设计 25

3.4 气缸的设计计算 27

3.5 结构钢强度校核 30

第4章 控制系统 33

第5章 总结与展望 38

5.1 全文总结 38

5.2 研究展望 38

参考文献 39

致谢 41

[资料来源:https://www.doc163.com]

下一篇:63T-M平头塔式起重机总体设计(含CAD零件图装配图)