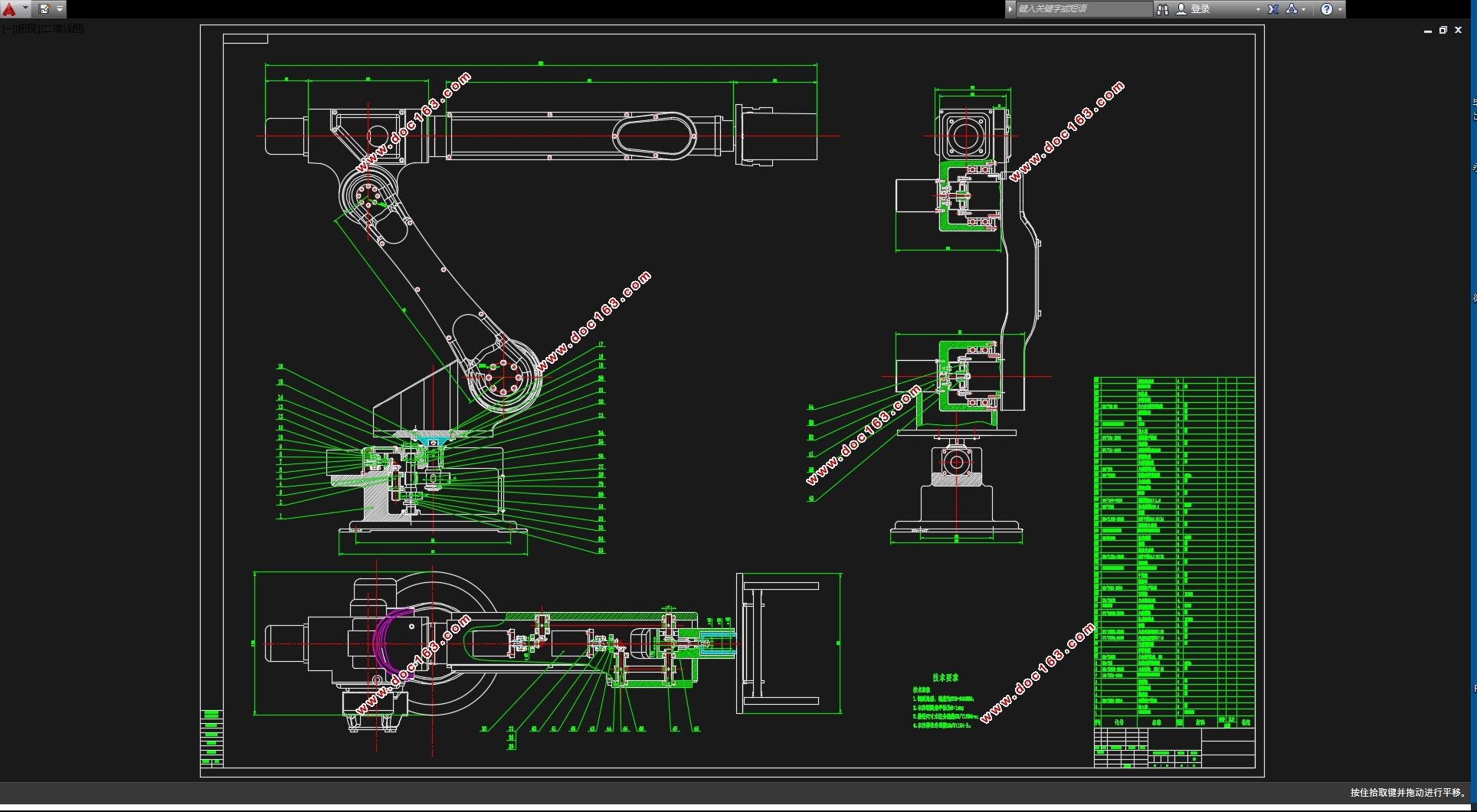

单臂式装卸机器人的设计(含CAD零件图装配图)

单臂式装卸机器人的设计(含CAD零件图装配图)(论文说明书10900字,CAD图7张)

摘要

近几十年来,装卸机器人作为高科技自动化生产设备之一,成为工业机器人的一个重要分支。其通过编程实现各种预期作业,兼具人和机器的优点,尤其体现在人的智能和适应性上。机器人准确性和完成作业的环境适应性,拥有广泛的国民经济发展空间。而发展装卸机器人的目的是为了从重复、繁重的体力劳动中解放出人力。

本文通过设定现有参数,进行多个方案对比,设计出一款装卸单臂的机械手。此外,大力发展装卸机械有广阔的前景。机器人的积极作用包括:部分代替人工操作;根据生产工艺的要求,按照一定的程序、时间、位置完成工件的搬运和装卸;操作焊接、装配所需的机具,优化工人劳动条件,显著提高劳动生产率,加快工业生产机械化、自动化的步伐。因此,许多国家都重视它,投入了大量的人力物力进行研究和应用。装卸机器人尤其在高温、高压、粉尘、噪声、放射性和污染场合具有广泛的应用价值。

关键词:装卸机械手设计

ABSTRACT

In recent decades, as one of the high-tech automated production equipment, the loading and unloading robots have become an important branch of industrial robots. They achieve various expected operations through programming and embody the advantages of both humans and machines, especially in intelligence and adaptability. With high accuracy and environmental adaptability, robots have broad space for development in national economy. The purpose of developing loading and unloading robots is to free people from repetitive and strenuous physical labor. [资料来源:http://www.doc163.com]

This article compares multiple schemes by setting current parameters and designs a single-arm mechanical hand for loading and unloading. In addition, developing loading and unloading machinery has broad prospects. The positive effects of robots include partial replacement of manual operations, fulfilling the requirements of production processes by following certain procedures, time and positions to complete the transportation and loading and unloading of workpieces, operating necessary tools for welding and assembly to optimize labor conditions, and significantly improving labor productivity, accelerating the industrial automation and mechanization. Therefore, many countries have attached great importance to it and invested a lot of human and material resources in researching and applying it. Loading and unloading robots have a wide range of application values, particularly in fields such as high temperature, high pressure, dust, noise, radiation and pollution.

Keywords: Handling Manipulator Design

[来源:http://Doc163.com]

本文的研究内容是有关单臂装卸机器手的设计。目前,国内汽车行业的总装线已经基本实现了规模化和机械化生产,自动化水平也相对较高。本文设计的机器手是一种用于汽车行业的装卸机器人。

设计参数参考:

单臂装卸:参考常规在线搬运单臂尺寸:3000mm*600mm*150mm;

最大搬运重量:500kg;

[资料来源:Doc163.com]

目录

摘要 1

ABSTRACT 2

一、绪论 4

1.1 引言 4

1.2国内外研究现状 4

1.3本文研究的主要内容 5

二、总体方案设计 6

2.1 数据参考 6 [资料来源:http://www.doc163.com]

2.2、总方案论述 6

2.3 结构与传动原理 7

2.4 总体方案设计 7

三装卸机器人大臂的结构设计 8

3.1 设计基本要求 8

3.2 机构设计 8

3.3 驱动系统选型 9

3.4 承载能力计算 9

四、装卸机器人末端结构设计 12

4.1 结构设计与校核 12

4.2 计算分析 20

4.3 传动轴的设计 21

五、机身结构的设计 24

5.1 齿轮设计 24

5.2 轴的设计 27

5.3 轴承校核 34

六、总结 39

七、致谢 40

八、参考文献 41 [来源:http://www.doc163.com]

上一篇:口服液检测剔瓶及贴标机构设计(含CAD零件装配图,SolidWorks三维图)

下一篇:大型车上下车自动伸缩脚踏板的设计(含CAD零件图装配图)