椭圆振动筛的设计(含CAD零件图装配图)

资料介绍:

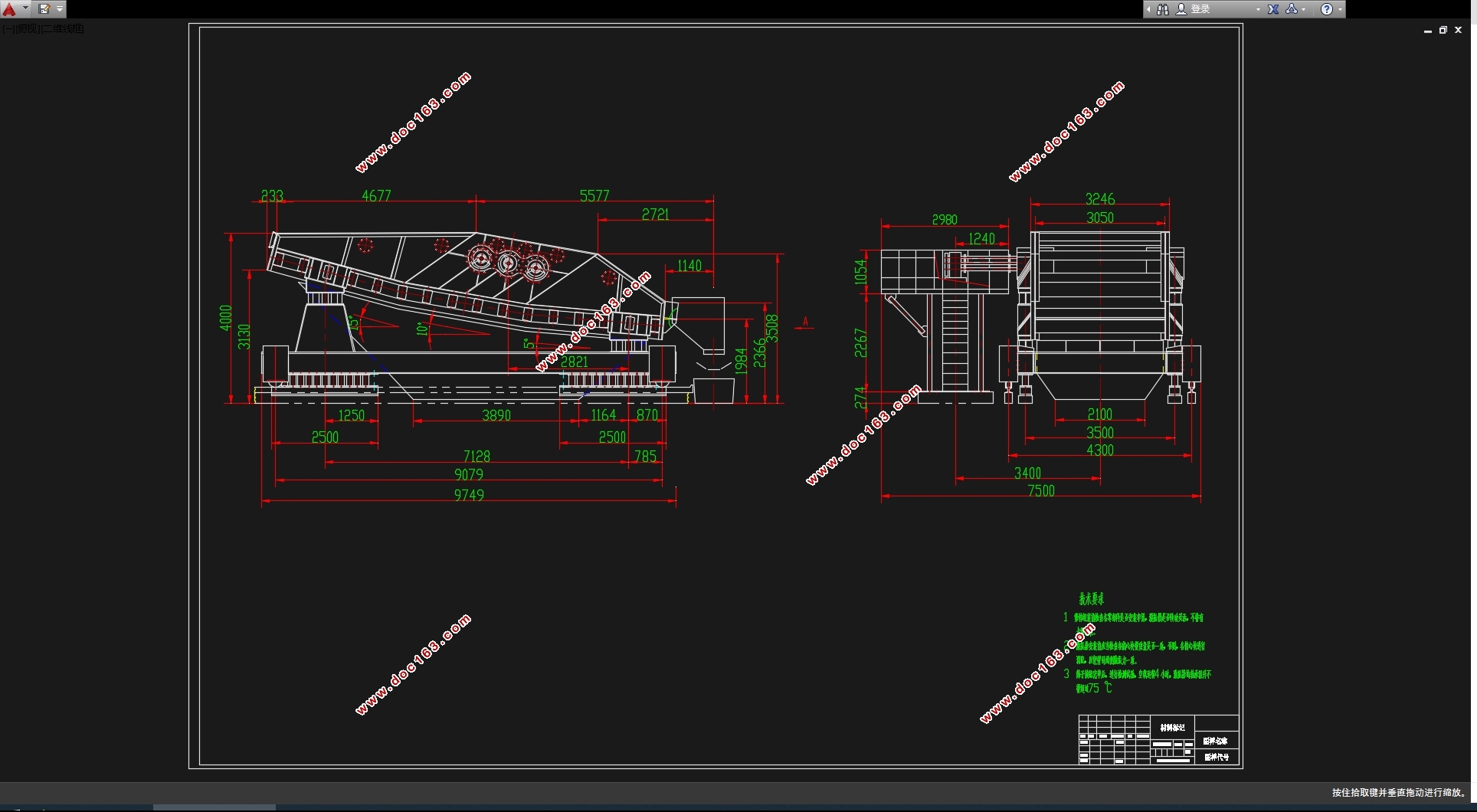

椭圆振动筛的设计(含CAD零件图装配图)(论文说明书20000字,CAD图6张)

摘 要

椭圆振动筛是矿业生产中广泛使用的机械之一,它是进行矿物筛选的关键设备,自19世纪第一台椭圆筛选及问世以来,椭圆振动筛就一直被广泛的应用于矿业中。因此,无论是设计阶段对椭圆振动筛的选择还是矿山企业在生产阶段对椭圆振动筛的管理都十分重视。同时许多椭圆振动筛的设计研究单位和生产厂家也对椭圆振动筛进行了很多研究工作,取得了很大进展,出现了多方面的研究方向。

最近几年,椭圆振动筛在外部系统方面取得的较为突出的成果。主要有减速传动装置的发展。原有的边缘传动出现了结构更加紧凑的紧密传动方式。

因为传动的工作性能直接影响着椭圆振动筛的性能和成本,有的甚至起决定性作用,传动装置在整个椭圆振动筛中占有十分重要的地位,所有本次设计主要以TDLS 3090 椭圆振动筛设计为基础。对椭圆振动筛各基本参数计算,电机的选择及计算,弹簧的设计及校核,振动器轴的设计,轴承计算选择,对带传动系统设计。对椭圆等厚冷矿振动筛进行评价与比较,确定合理的设计方案。

关键词:椭圆振动筛,设计,校核

ABSTRACT

[资料来源:http://www.doc163.com]

The elliptical vibrating screen is one of the widely used machinery in mining production, and it is a key equipment for mineral screening. Since the first elliptical screening machine was introduced in the 19th century, the elliptical vibrating screen has been widely used in mining. Therefore, both the selection of elliptical vibrating screens during the design phase and the management of elliptical vibrating screens by mining enterprises during the production phase are highly valued. At the same time, many design and research units and manufacturers of elliptical vibrating screens have also conducted a lot of research work on elliptical vibrating screens, and have made great progress, resulting in various research directions.

In recent years, elliptical vibrating screens have achieved outstanding results in external systems. The main development is the reduction transmission device. The original edge drive has introduced a more compact compact compact transmission method.

Because the working performance of the transmission directly affects the performance and cost of the elliptical vibrating screen, and some even play a decisive role, the transmission device plays a very important role in the entire elliptical vibrating screen. All of this design is mainly based on the TDLS 3090 elliptical vibrating screen design. Calculation of basic parameters of elliptical vibrating screen, selection and calculation of motor, design and verification of spring, design of vibrator shaft, selection of bearing calculation, and design of belt transmission system. Evaluate and compare the elliptical and equal thickness cold ore vibrating screen to determine a reasonable design plan.

[来源:http://Doc163.com]

Keywords: elliptical vibrating screen, design, verification

[资料来源:http://Doc163.com]

目录

摘 要 1

ABSTRACT 2

[来源:http://Doc163.com]

1 绪 论 1

1.1 引言 1

1.2国内外研究现状 1

1.2.1国内振动筛研究现状 1

1.2.2国外振动筛研究现状 2

2 总体方案设计 3

2.1 椭圆振动筛的工作原理 3

2.2整体方案的确定及结构特点 3

2.2.1筛箱 3

2.2.2激振器 8

2.2.3联轴器 9

2.2.4支撑装置 10

2.3振动筛基本参数的计算 11

2.3.1筛面的倾角( ) 11

2.3.2抛射角( ) 12

2.3.3振动强度K的选择 12

2.3.4抛射强度( ) 12

2.3.5振幅和频率 (A、n) 12

2.3.6实际振动强度的校核 13

2.3.7振动筛参振重量的计算 13

2.3.8激振器偏心块质量及偏心距的确定 13

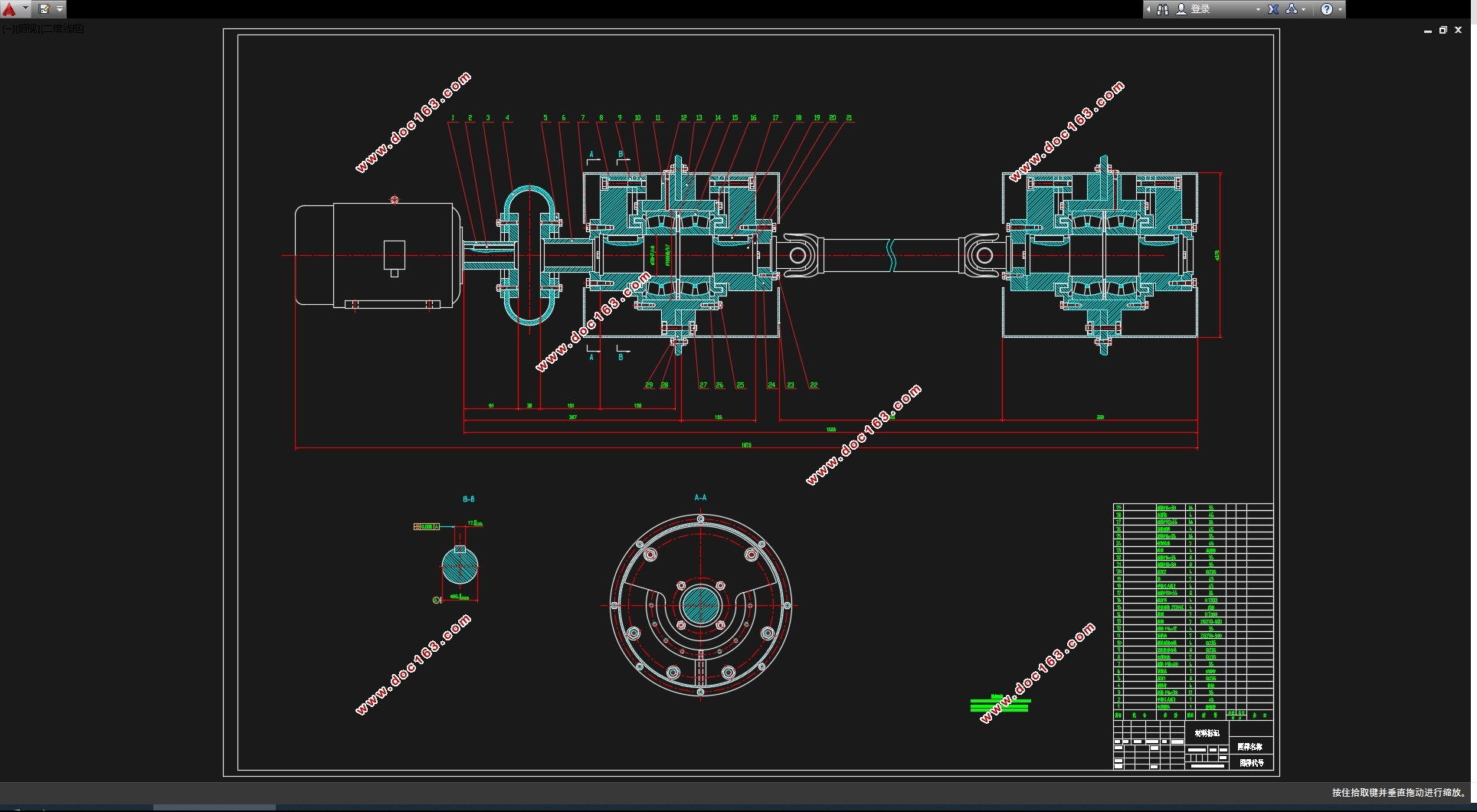

3 传动部分设计 14

[资料来源:https://www.doc163.com]

3.1 电机的选择 14

3.1.1负载特性 14

3.1.2用于筛选机拖动的几种类型的电机 14

3.2大小齿轮的设计 15

3.2.1边缘传动用大小齿轮的材料 15

3.2.2 大齿圈直径的确定 16

3.2.3 齿形的确定 16

3.2.4 模数的确定 16

3.2.5齿轮强度校核 16

3.2.6大小齿轮速比的确定 19

3.2.7齿数的确定 19

3.2.8齿轮各部分几何尺寸的计算 20

3.2.9齿圈与磨体的联接 20

3.2.10大齿圈的结构设计 21

3.3轴的设计 23

3.3.1选择轴的材料 23

3.3.2输出轴上的功率 ,转速 和扭矩 23

3.3.3求作用在齿轮上的力 23

3.3.4轴径的初步估算 24

3.3.5小齿轮轴的结构设计 24

3.3.6 轴的强度的精确校核 25 [资料来源:Doc163.com]

3.3.7连接轴的结构设计 27

3.4传动轴承的计算与选型 27

3.4.1轴承的选用原则 27

3.4.2轴承校核 27

3.5键的设计 28

3.6轴承盖的设计 29

3.7 弹簧的设计与校核 30

3.7.1初算弹簧所承受的载荷 30

3.7.2弹簧材料和直径 30

3.7.3弹簧的刚度和变形计算 31

3.7.4弹簧的校核 32

3.7.5结构参数的计算 33

3.7.6疲劳强度校核 33

3.7.7稳定性计算 33

3.8 带传动设计 34

4 设备的环保与经济性分析 36

4.1 环保性分析 36

4.2 经济型分析 36

结 论 38 [资料来源:http://Doc163.com]

下一篇:移动式肉羊饲喂装置设计(含CAD装配图,PROE三维图)