一种变刚度软体机械手的设计(含STP三维图)

一种变刚度软体机械手的设计(含STP三维图)(任务书,开题报告,论文说明书15000字,STP三维图)

摘要

本文是在现有的软体机械手的研究基础上,采用气动驱动方式,将颗粒阻塞效应用于机械手中,设计了一种可变刚度软体机械手;通过实验验证了颗粒阻塞效应的实际效果,估算了机械手阻塞后的整体刚度。

本文的主要工作包括:

1)气动手指的结构设计和制作:利用材料和结构的各向异性设计了软体手指,通过颗粒阻塞效应设计了变刚度层,并设计了浇铸成型的加工工艺。通过组合这两种部件,设计了本文中气动软体机械手;

2)搭建了气路系统:为了进一步驱动软体机械手,本文设计了配套的气路系统,分别控制软体爬行机器人的弯曲层与变刚度层的内部气压,完成软体机械手的抓取动作

3)基于有限元仿真系统地探究了软体手指的结构参数对其驱动特性的影响:借助有限元仿真软件选取弯曲层材料、空腔数量以及空腔间壁厚三个参数探究了其对软体手指弯曲特性的影响规律,通过综合调控这些结构参数可使软体机械手具备更好的特性,这对后续的研究工作有很好的指导意义。

4)阻塞效应的实验验证:搭建验证阻塞效应的试验台,得到不同压力,不同负载下变刚度层的侧向位移,并将变刚度层看作悬臂梁模型,根据实验数据估算变刚度层的刚度(弹性模量),最终估算软体手指的弹性模量。

[资料来源:www.doc163.com]

关键词:软体机械手;颗粒阻塞效应;变刚度;有限元仿真

Abstract

Based on the research of the existing soft manipulator, this paper combines the pneumatic driving method and granular jamming to design a variable stiffness soft gripper. Meanwhile, the test bench is established to verify granular jamming effect, and the overall stiffness is estimated according to the experimental data. The main work of this paper includes the following things.

1) The structural and fabrication design of pneumatic finger: The paper uses the anisotropy of material and special structures to design the soft gripper fingers, then designs the casting molding processing technology. Also,the variable stiffness layer is designed by granular jamming effects. By combining these two components, the pneumatic soft gripper is designed.

2) Construction of multi-gas system: In order to drive the soft gripper, this paper designs a multi-pneumatic system to control the internal pressure of the bending layer and the variable stiffness layer of the soft gripper, thus driving the grasping action of the soft gripper. [资料来源:www.doc163.com]

3) Based on the finite element simulation system, the influence of the structural parameters of the soft finger on its bending characteristics is explored: The finite element simulation software is used to explore the influence of the bending layer material, the number of cavities and the wall thickness between the cavities on the bending characteristics of the soft finger. Better characteristics of soft grippers can be achieved by comprehensively regulating these structural parameters, which has a good guiding significance for the subsequent research work.

4) Experimental verification of granular jamming: The paper sets up a test bench to verify the granular jamming effect, and obtains lateral displacement of the variable stiffness layer under different pressures and loads. Considering the variable stiffness layer as a cantilever beam model, the paper estimates the stiffness (Elastic Modulus) of variable stiffness layer according to experimental data, thus estimating the overall elastic modulus of soft grippers [版权所有:http://DOC163.com]

Key Words:soft gripper; granular jamming; variable stiffness; finite element simulation

[资料来源:Doc163.com]

[资料来源:https://www.doc163.com]

目录

第1章 绪论 1

1.1课题的研究背景和意义 1

1.2 软体机械手国内外研究现状 2

1.2.1线缆驱动软体机械手 2

1.2.2气动软体机械手 3

1.2.3 SMA驱动软体机械手 4

1.2.4 EAP驱动软体机械手 5

1.2.5 其他智能材料驱动软体机械手 6

1.2.6 国内软体机械手研究现状 7

1.3 本文的主要研究内容 8

第2章 软体机械手结构设计 9

2.1总体方案的设计 9

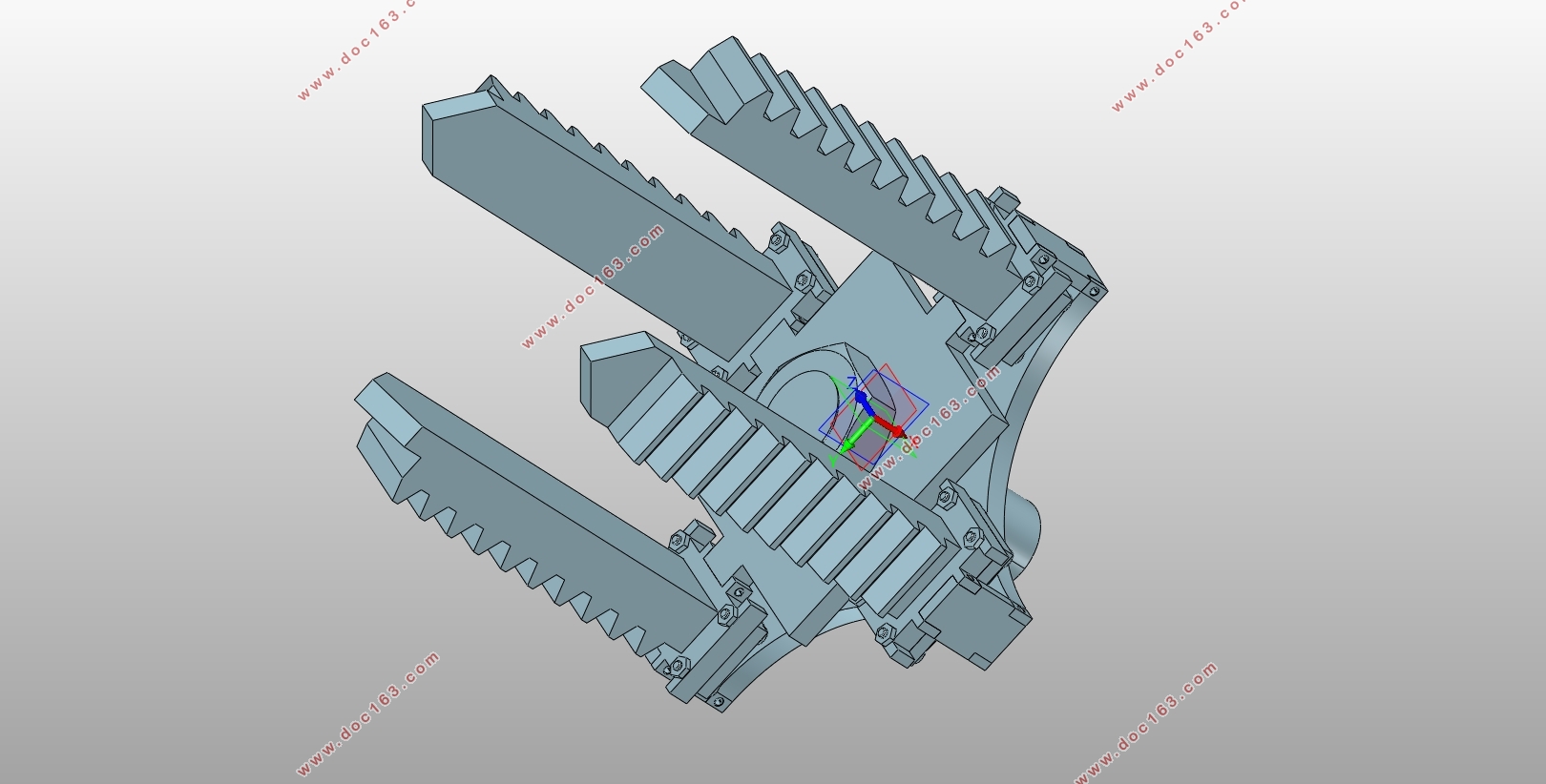

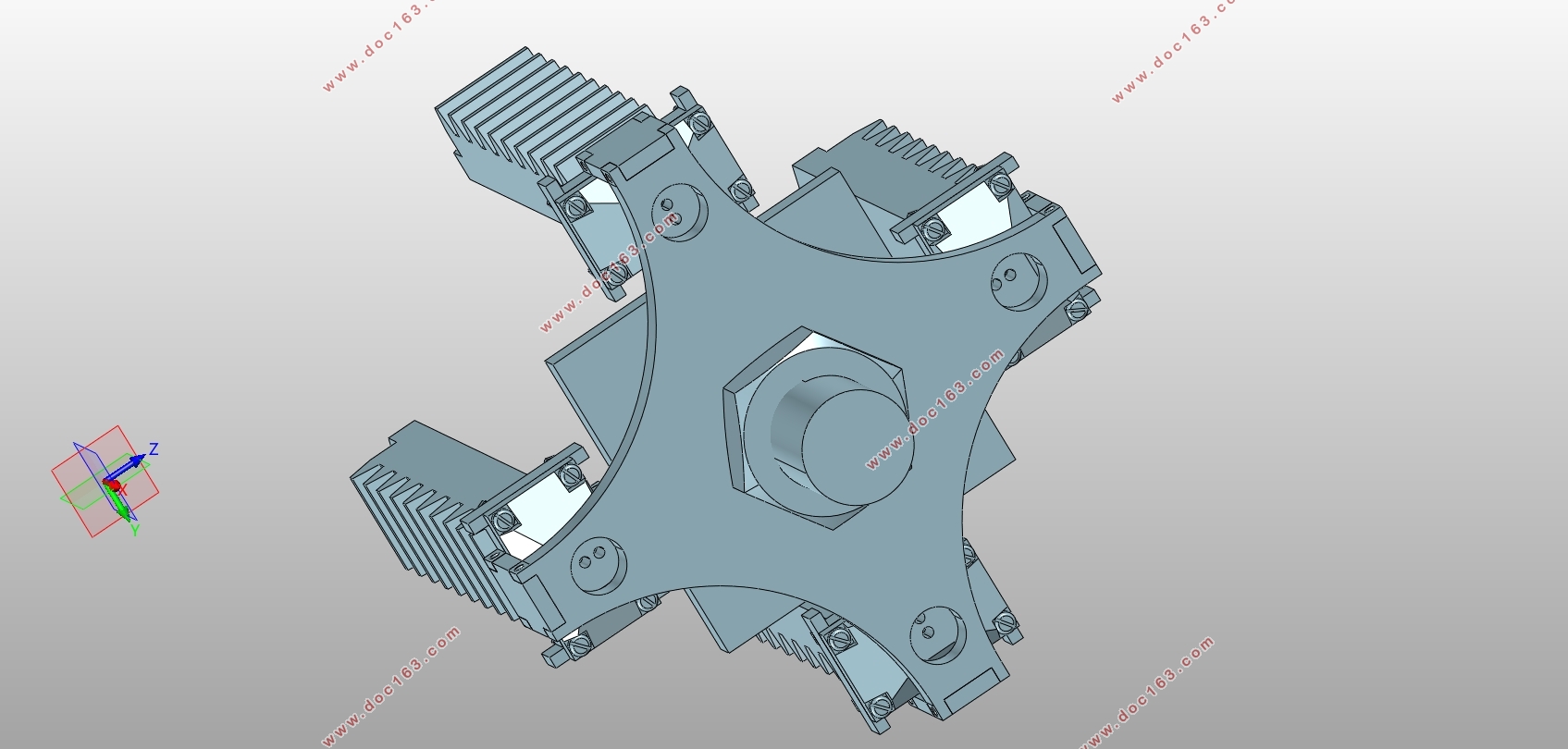

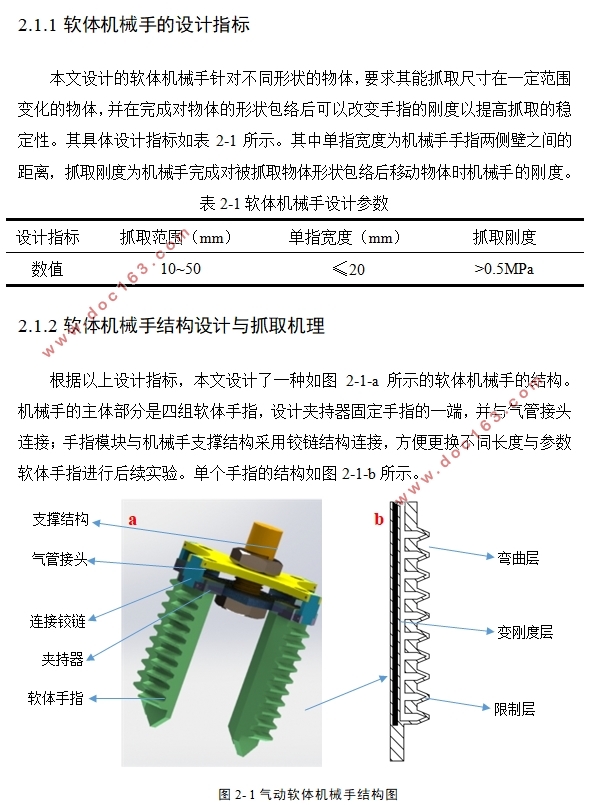

2.1.1软体机械手的设计指标 9

2.1.2 软体机械手结构设计与抓取机理 9

2.2弯曲模块的设计与制作 10

2.2.1弯曲模块的弯曲驱动器原理 10

2.2.2 弯曲模块的材料选择 11

2.2.3 弯曲模块结构的设计 12

2.2.4 弯曲模块的制作工艺 12

2.3变刚度模块设计与制作 14

2.3.1颗粒阻塞的机理 14

2.3.2阻塞效应影响因素 15

2.3.1变刚度层的制作工艺 15

第3章 气路平台的设计及时序控制 16

3.1气路平台硬件的选择 16

3.2 气路平台控制原理 17

第4章 结构参数对机械手弯曲特性影响的有限元分析 18

4.1软体手指有限元建模 18

4.1.1超弹体材料的材料模型 18

4.1.2软体弯曲驱动器的力学分析 19

4.1.3有限元模型的建立 20

4.2各参数对软体弯曲驱动器弯曲特性的影响 22

4.2.1弯曲层材料对弯曲特性的影响探究 23

4.2.2空腔数量对弯曲特性的影响探究 24

4.2.3空腔间壁厚对弯曲特性的影响探究 25

4.3 仿真结论 26

第5章 变刚度层阻塞效应的实验验证与分析 28

5.1阻塞效应实验验证 28

5.2变刚度层的刚度计算 29 [来源:http://Doc163.com]

第6章 总结与展望 33

参考文献 35

致 谢 37

下一篇:YSK-600A四柱油压机机械结构设计(含CAD零件图装配图)