动车轮对组装机机械系统设计(含CAD图,ANSYS)

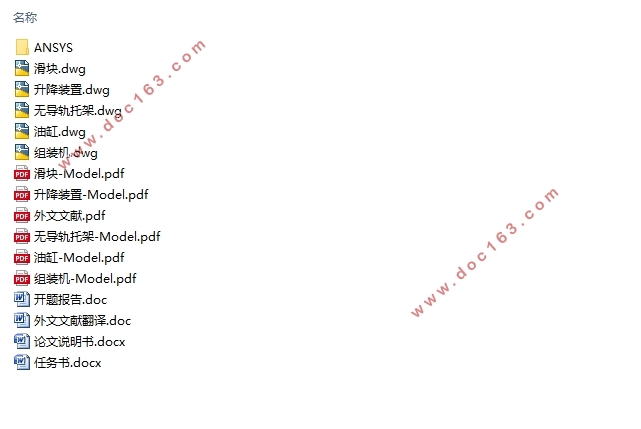

动车轮对组装机机械系统设计(含CAD图,ANSYS)(任务书,开题报告,外文翻译,论文说明书14000字,CAD图5张,ANSYS)

摘要

轮对是动车走行部的重要部件,它承载着动车的全部重量,并沿着动车轨道作高速运行。随着动车组轴重的增加和运行速度的大幅度提升,动车的安全运行受轮对的组装质量的影响越来越大,对轮对组装的安全性与可靠性的要求也越来越高。目前动车轮对的组装模式主要有注油压装、热装和无注油压装组装等。现阶段我国大多数轮对组装都停留在上世纪五十年代的水平上,远不能满足高速发展的铁路运输对轮对组装质量的需求。

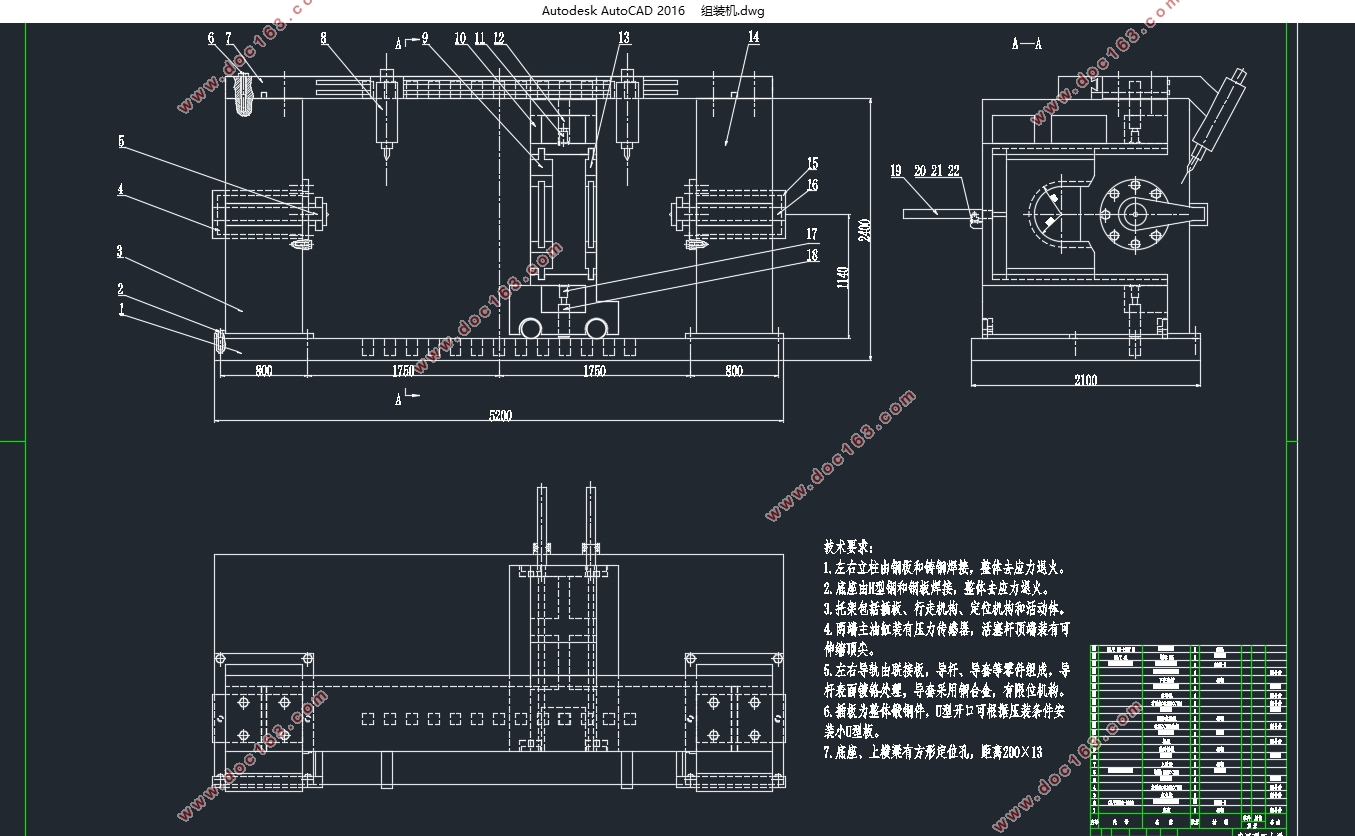

本文在我国现有轮对组装机的基础上充分吸收国外先进的轮对组装技术,并结合我国具体实际,提出了一种新型动车轮对组装机。该类型轮对组装机集压装与卸载于一体,通过移动不同厚度的插板可实现对轮对和制动盘的一次性压装与卸载,解决了老式轮对组装机掉头压装与卸载、轮对和制动盘分开压装、卸载的问题,提高了动车轮对压装的质量和可靠性。主要研究工作:动车轮对组装机总体方案的设计,确定动车轮对组装机的总体构成;对关键零部件进行设计与校核,并绘制工程图;对关键零部件进行三维建模,利用ANSYS完成有限元分析,校核强度;分析动车轮对组装机的组装工艺,对其组装过程进行说明。 [版权所有:http://DOC163.com]

关键词:轮对组装机;零部件设计;有限元分析;组装工艺

Abstract

The wheel is an important part of the moving car, it is full of the load of the motor vehicle,and along the track for high-speed operation. With the increase in the weight of the axle and the speed of the operation, the safe operation of the motor vehicle is more and more affected by the assembly quality of the wheel, and the reliability of the assembly of the wheel is getting higher and higher. At present, the main way of assembling the wheel is oil injection, hot and no oil pressure assembly. At present, most of China's railway wheel assembly workshop assembly technology are stuck in the last century,the level of the fifties, far from the current high-speed development of the railway needs.

On the basis of the existing wheel assembly machine in our country, this paper fully absorbs the foreign advanced wheel assembly technology, and puts forward a new type of wheel assembly machine in combination with our concrete reality. The wheel assembly machine through a different thickness of the board can be achieved on the wheel and brake disc of the one-time press-fit, to solve the old wheel on the assembly machine U-turn press, wheel and brake disc separately press the problem, Improve the accuracy and reliability of the wheel loader. The main research work of this paper: The overall design of the wheel assembly machine assembly program to determine the overall composition of the wheel assembly machine; The design and verification of key components, and drawing drawings; Three-dimensional modeling of key components, the use of ANSYS to completethe finite element analysis, check the strength; Analysis of the assembly process of the assembly wheel of the moving wheel, and the assembly process will be described. [资料来源:http://Doc163.com]

Key Words:wheel assembly machine;parts design ;finite element analysis;assembly process

[来源:http://www.doc163.com]

目录

第1章绪论 1

1.1 背景及意义 1

1.2 国内外轮对组装机现状 1

1.2.1 国内轮对组装机现状 1

1.2.2 国外轮对组装机现状 3

第2章动车轮对组装机总体设计方案 4

2.1 设计思想 4

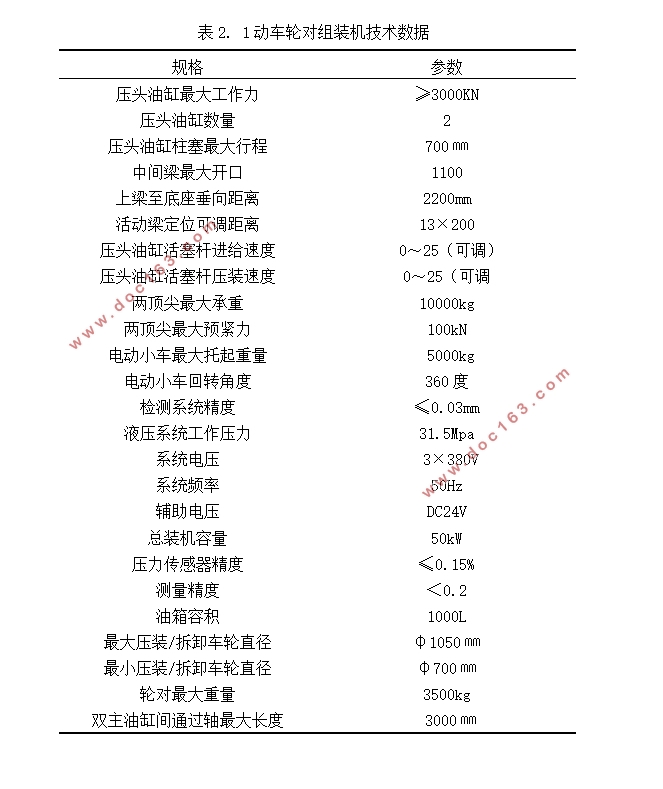

2.2 性能指标 4

2.3 轮对组装机总体设计方案 6

2.3.1 机械部分 6

2.3.2 测量系统 6

2.3.3 液压系统 6

2.3.4 控制系统 7

2.3.5 输入与输出系统 7

2.3.6 按钮站 7

第3章动车轮对组装机机械系统设计 8

3.1 主机结构 8

3.2 活动梁装置 9

3.3 送料小车 10

第4章关键零部件设计与校核及有限元分析 12

4.1 U型滑块插板 12

4.1.1 U型滑块插板设计与校核 12

4.1.2 型滑块插板有限元分析 13

4.2滑块油缸 16

4.2.1 滑块油缸的设计与校核 16

4.2.2 活塞杆稳定性有限元分析 17

4.3 升降装置 21

4.3.1 升降装置的设计与校核 21 [版权所有:http://DOC163.com]

4.3.2 托臂有限元分析 23

4.4 活动梁装置 27

4.4.1 活动梁装置的设计与校核 27

4.4.2 活动梁装置有限元分析 29

第5章动车轮对组装工艺的设计 32

5.1 送料小车上料 32

5.2 制动盘压装 33

5.3 车轮压装 34

5.4 送料小车卸料 35

第6章结论 36

参考文献 37

附录 39

致谢 44

上一篇:液压助力转向器性能试验台设计(含CAD零件图装配图)

下一篇:离合器变曲线螺旋槽加工设备设计(含CAD零件图装配图)