含裂纹压力管道的有限元分析(含CAD零件图装配图)

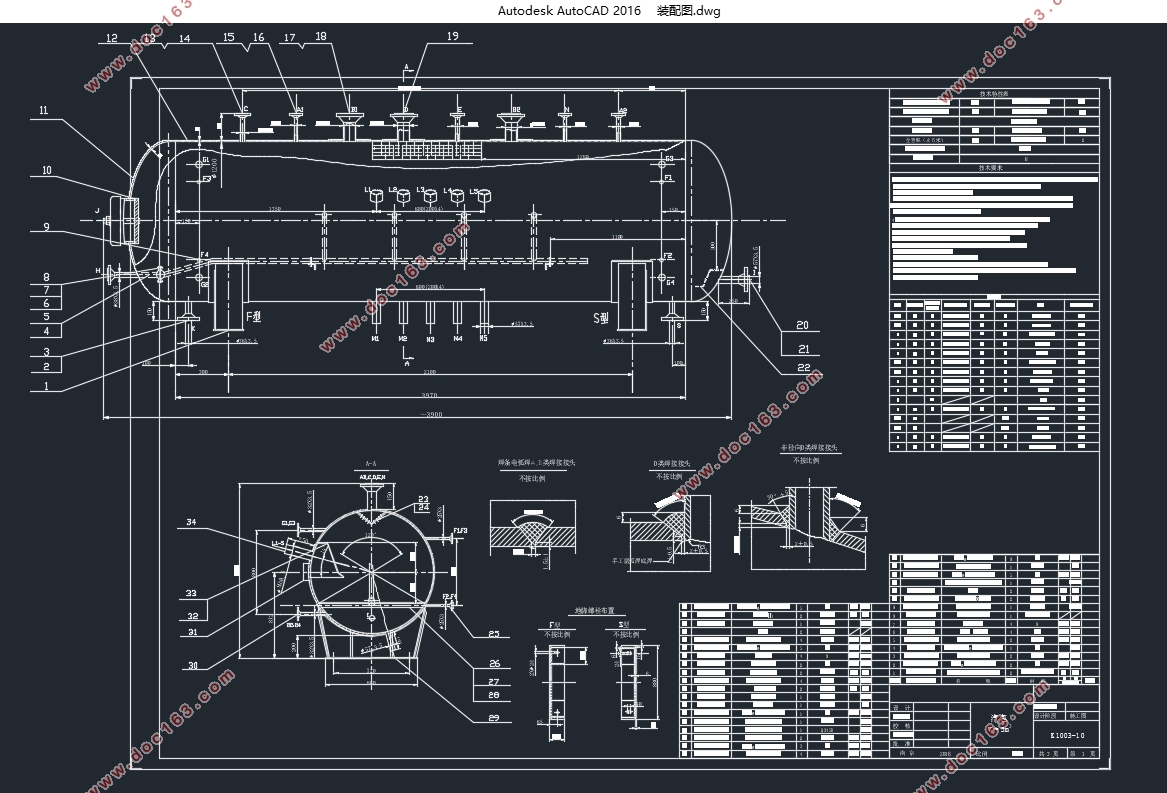

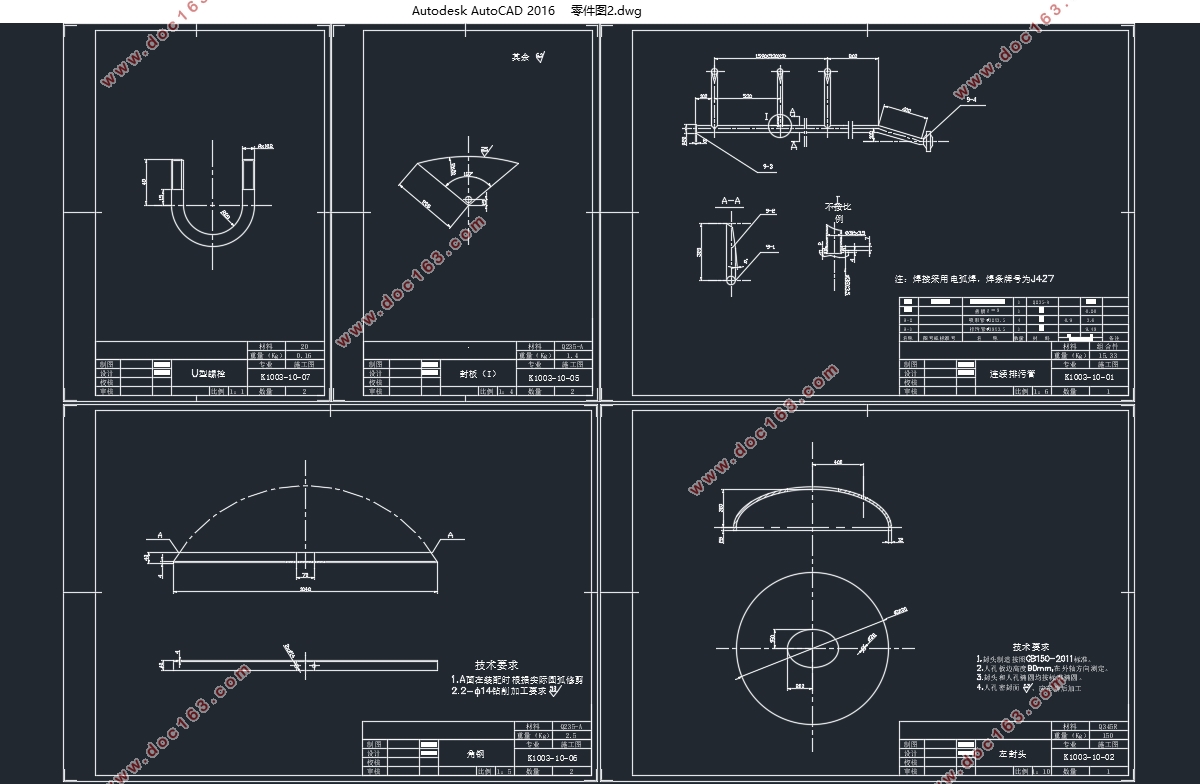

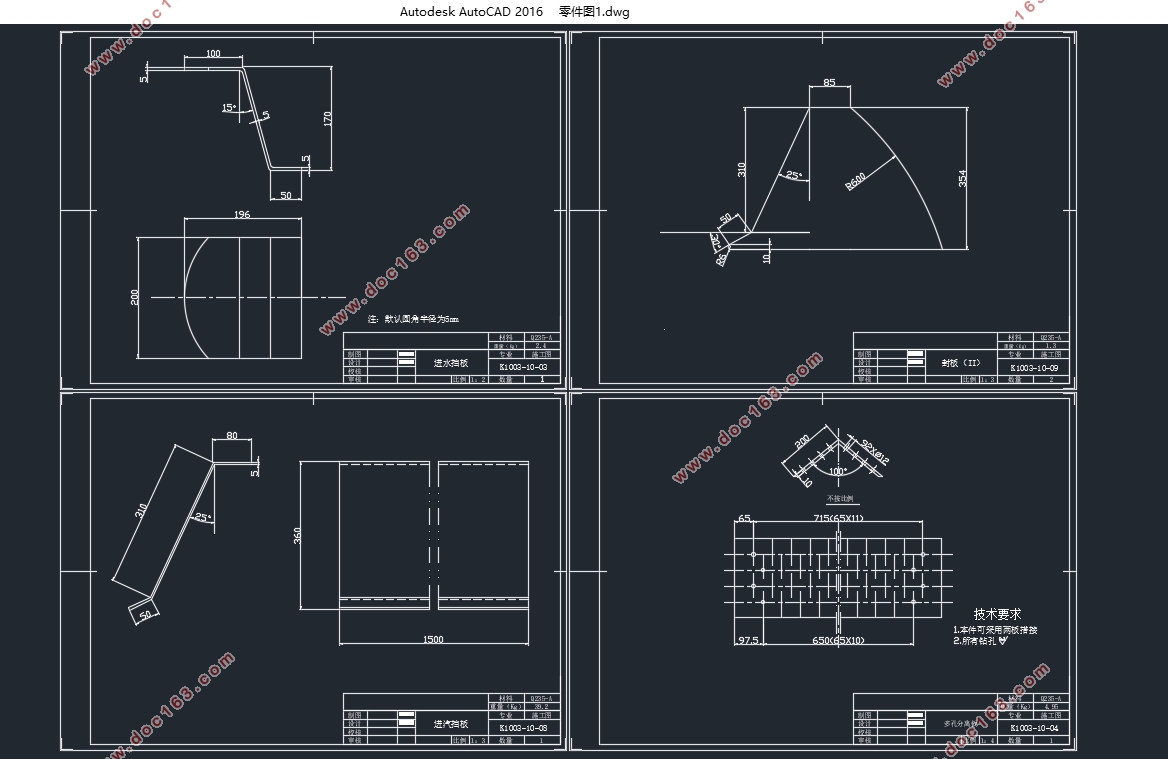

含裂纹压力管道的有限元分析(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书9000字,CAD图3张,答辩PPT)

摘要

国际上广泛使用压力管道的适用性安全评价技术,断裂力学是安全评价的理论基础。本文在断裂力学的基础上,通过有限元分析方法,对含环向穿透裂纹和双穿透裂纹直管的断裂参量进行了计算和研究。在ABAQUS软件中模拟了含环向穿透裂纹和双穿透裂纹直管的断裂行为,建立了有限元模型,对所研究直管进行有限元分析和求解,计算得出其极限载荷和J积分。本文研究了单双裂纹的应力应变场,应力强度因子及极限载荷分析。通过单双裂纹的应力强度因子和极限载荷对比分析,得出一些规律性的结论。

关键词:环向穿透裂纹;有限元;极限载荷;J积分

Finite Element Analysis of Pressure Piping With Cracks

Abstract

The application of pressure pipeline is widely used in the world, and the fracture mechanics is the theoretical basis of the safety evaluation. Based on fracture mechanics and finite element analysis, the fracture parameters of a straight pipe with a circumferential crack and a through crack have been calculated and studied. With ABAQUS software the fracture behavior of pipe containing circumferential penetrating crack and double penetration cracks was simulated. The finite element model was established. Finite element analysis and solution of the straight pipe were made to obtaine the limit load and J integral. In this dissertation, the stress and strain fields, stress intensity factors, and ultimate load analysis of single and double cracks were studied. Through the comparison of the stress intensity factor and the ultimate load of single and double cracks, some regular conclusions were obtained.

[资料来源:http://doc163.com]

Key words: circumferential through crack; finite element method; limit load; J integral

[资料来源:Doc163.com]

目录

摘要 I

Abstract I [资料来源:http://www.doc163.com]

第一章 绪论 1

1.1 研究背景 1

1.2 断裂力学 1

1.3极限载荷的研究 2

1.4 J积分理论 3

1.5 本文主要研究的内容 5

第二章 含环向穿透裂纹直管的研究 6

2.1 有限元分析 6

2.1.1有限元软件介绍 6

2.1.2有限元分析过程 6

2.1.3 模型的建立 6

2.2 模型的建立 7

2.3 极限载荷计算分析 10

2.4 J积分的分析和比较 13

2.4.1 沿壁厚方向J积分的变化 13

2.4.2 不同角度裂纹J积分的比较 15

2.5 小结 15

第三章 含双穿透裂纹直管的研究 16

3.1 双穿透裂纹直管有限元分析 16

3.2 极限载荷的分析比较 17

3.3 J积分的分析及比较 18

3.3.1 沿壁厚方向J积分的变化 18

3.3.2 不同角度裂纹J积分的比较 22

3.4 双裂纹管道与单裂纹管道断裂参数的比较 24

3.4.1 极限载荷的比较 24

3.4.2 J积分的比较 25

3.5 小结 26

第四章 结论与展望 27

参考文献 28

致谢 30 [来源:http://Doc163.com]

上一篇:40T-m塔式起重机总体设计(含CAD零件图装配图)

下一篇:钢球疲劳试验机—机械系统设计(含CAD图,SolidWorks三维图)