双伺服动力刀架刀具驱动模块优化(含CAD图,PROE三维图)

双伺服动力刀架刀具驱动模块优化(含CAD图,PROE三维图)(任务书,开题报告,论文说明书13000字,CAD图11张,PROE三维图)

摘要

动力刀架是数控车床和车铣复合加工中心最普遍的一种辅助装置,它能够实现机床的刀具储备、刀具的自动交换和装夹刀具完成切削加工等多种功能。双伺服动力刀架属于中高档刀架,其转位和动力刀具是由两个动力源所驱动的,它的性能直接影响数控机床的加工精度和加工效率。刀架驱动模块结构参数是影响刀架性能的关键因素之一,因此本论文基于对某型号双伺服动力刀架驱动模块应力分析,为提高其传动平稳性针对六级七齿轮的传动方案进行优化。根据优化结果,刀具驱动模块的传动平稳性能及齿向受力状态均有所改善,在一定程度上提高了切削加工的精度及稳定性,降低了受力不均并可延长刀架的使用寿命。本研究为动力刀架及相关结构的分析优化提供一定的参考。

关键词:动力刀架刀具驱动模块优化设计齿轮传动

Optimization of Tool Drive Module for Double Servo Driven Turret

Abstract

The power tool turret is the most common auxiliary device for CNC lathes and turning and milling compound machining centers. It can realize multiple functions such as tool storage, automatic exchange and clamping tool cutting for CNC lathes and turning and milling machining centers. The indexing of the double-servo power tool rest and the drive of the power tool are driven by different power sources, respectively. Its performance directly affects the machining accuracy and machining efficiency of the CNC machine tool. The structural parameters of the tool carrier driving module are one of the key factors affecting the performance of the tool turret. Therefore, this paper is based on the analysis of the stress of the drive module of a certain type of dual servo powered tool carrier and optimized for the transmission stability of the six-grade seven gear. . According to theresultsofoptimization, the smooth of driving performance and tooth-tooth force status of the tool driving module are improved, which improves the precision and stability of the cutting processing to a certain extent, reduces the uneven stress and can prolong the service life of the tool holder. . This study provides a certain reference for optimization of the dynamic tool holder and related structures.

KeyWords:Power tool Turret ;drive module ofTool ; optimization design ;gear drive

[资料来源:http://Doc163.com]

目录

摘要 II

Abstract III

第一章绪论 1

1.1课题背景及意义 1

1.2研究现状 2

1.3课题研究的意义 4

1.4 主要研究内容 4

[资料来源:http://Doc163.com]

第二章 优化方案对比及经济性分析 6

第三章 动力刀架的结构及工作原理 7

3.1数控刀架的介绍及分类 7

3.2动力刀架功能部件介绍 8

3.3 AK33125双伺服动力刀架的工作原理 8

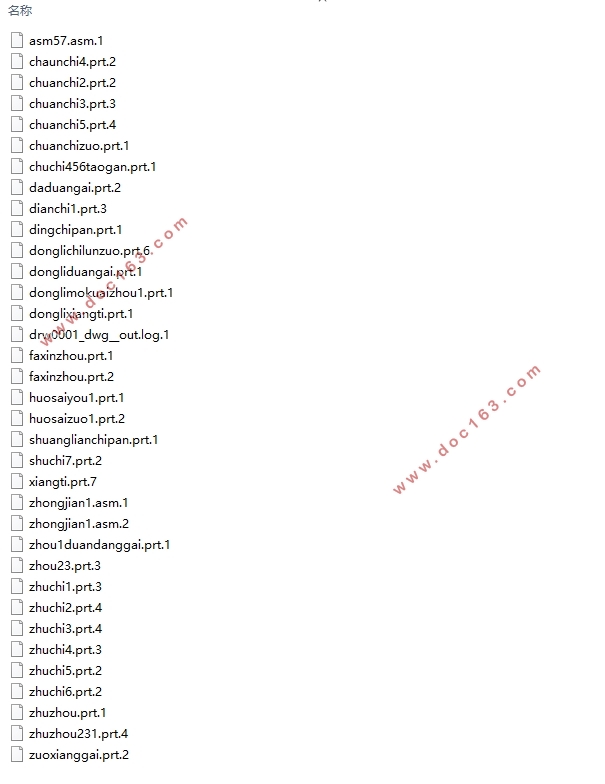

第四章AK33125双伺服动力刀架的建模 12

4.1主传动及主轴的建模 12

4.2活塞和三联齿盘的建模及工作原理 13

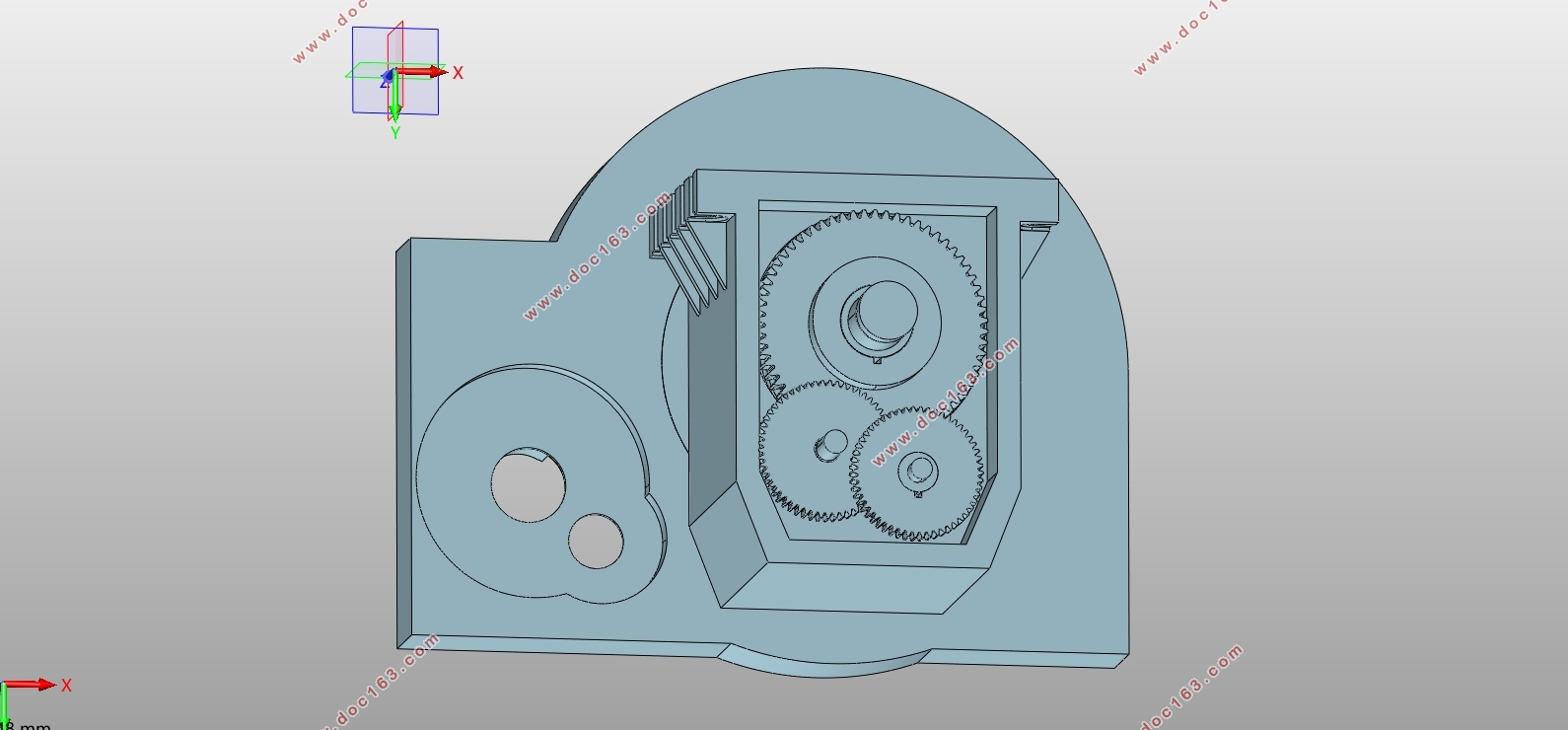

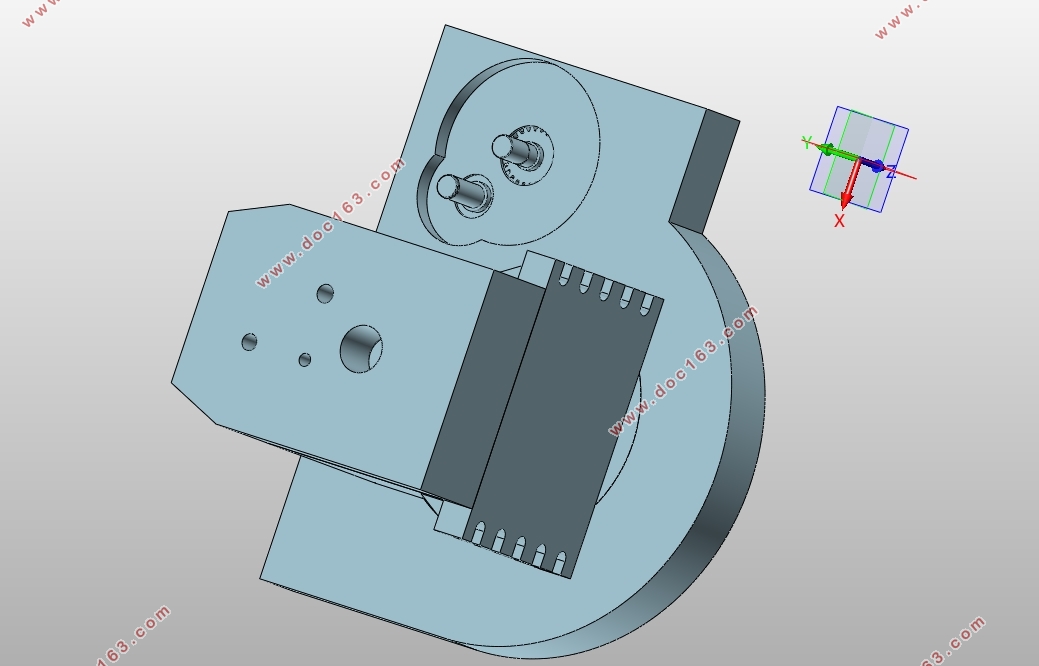

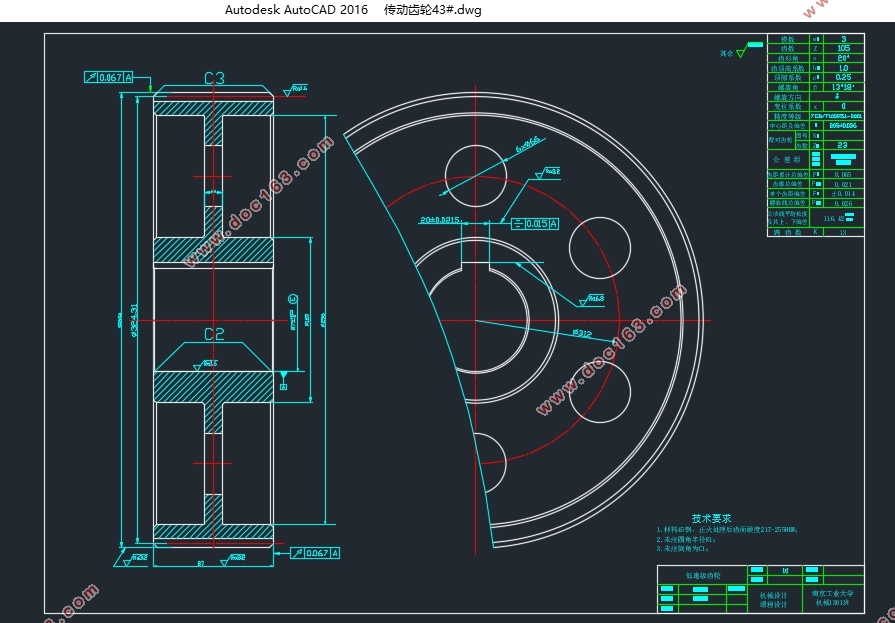

4.3动力传动模块的建模 15

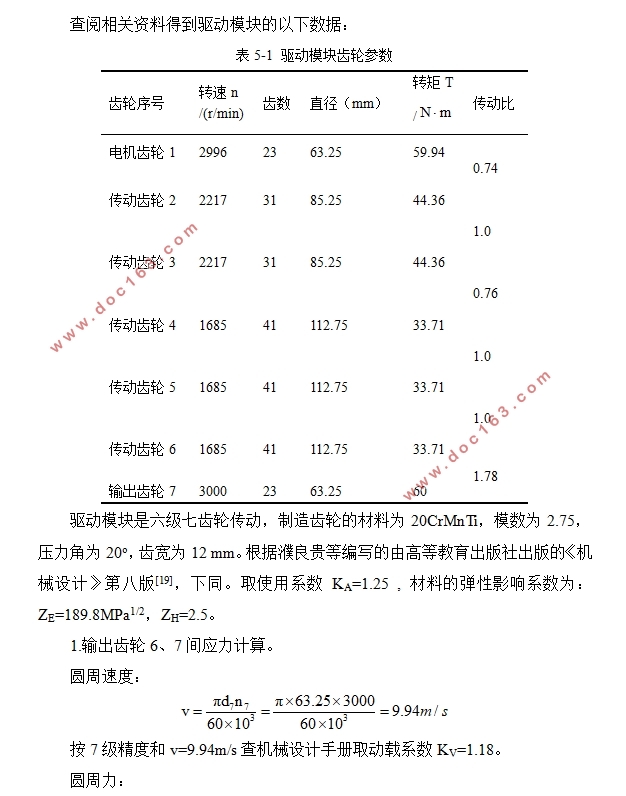

第五章 驱动模块计算及优化 17

5.1齿轮的受力计算 17

5.2优化计算 23

5.3其余各模数的优化计算 25

5.4优化情况与结论 34

第六章 总结与展望 37

参考文献 38

致谢 40 [资料来源:http://doc163.com]

上一篇:DZQ250-8,9,10,11.2通用减速机系列设计(含CAD零件图装配图)

下一篇:搅拌测试平台液压升降系统的设计(含CAD零件图装配图)