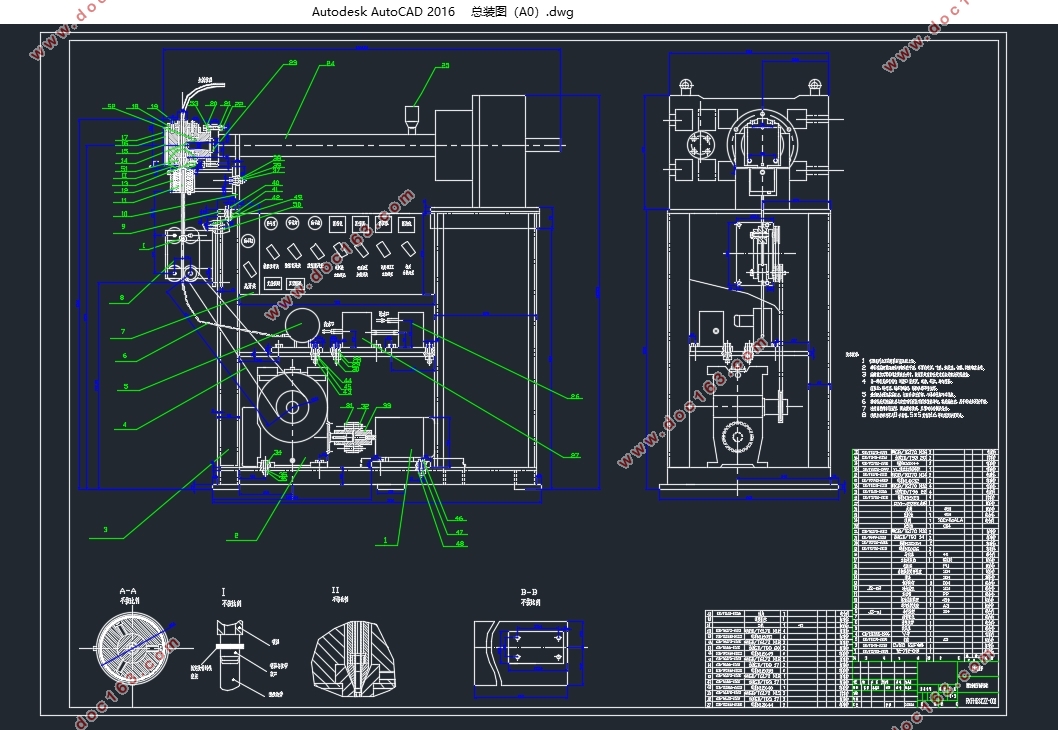

柔性复合管装置设计(含CAD零件图装配图)

柔性复合管装置设计(含CAD零件图装配图)(开题报告,外文翻译,论文说明书7000字,CAD图9张)

该复合管为进入人体体腔内的导管、其生产工艺要求管道分段力学性能差异,管道分层制作,对温度、含氧量等有较高工艺要求,对新材料、复合材料选用及相应生产设备进行了解。根据工艺要求进行生产装置设计。

按照现代模具工业技术人员必须具备正确设计成型模具和合理制定塑料成型工艺的知识、技术和能力的人才培养。本设计分为7章,介绍了柔性复合管成型在工业生产中的重要地位。第一章介绍了主要设计参数等,第二章介绍了设计柔性复合管的简明流程功能图,让人一眼就能清晰的了解整个设计流程,第三章为设计计算参数,第四章介绍了整个成型系统的组成,结构,设计以及流程,第五章则介绍了复合管从模具口出来是怎么冷却的以及设计参数,第六章为牵引系统的设计,电机的选择,减速器的选取,轴承、轴、联轴器的选择以及牵引系统的布置。第七章为整个装置的支架设计。

Flexible composite pipe plant design

Abstract

The composite tube into the body cavity of the catheter body, and its production process requires mechanical performance differences pipeline segments.Hierarchical production pipeline, temperature, oxygen content, etc. have a higher technological requirements for new materials, composite materials molding equipment selection and appropriate to understand. According to the technical requirements for production equipment design.

[版权所有:http://DOC163.com]

According to the modern mold industry technicians must have the correct and rational design mold plastic molding process to develop the knowledge, skills and abilities of the personnel training objectives and requirements, the design is divided into seven chapters, introduces flexible composite pipe forming in industrial production in an important position . The first chapter introduces the main design parameters, etc. The second chapter describes the design process of flexible composite pipe concise functional diagram, people will be able to a clearer understanding of the entire design process, design and calculation of parameters for the third chapter, the fourth chapter describes the the whole forming the composition, structure, design and process, the fifth chapter describes the composite pipe out of the mouth from the mold is cooled and how the design parameters, the sixth chapter of the traction system design, choice of motor, reducer selection, bearings, shaft, coupling selection and arrangement of the traction system. Chapter VII of the stent design for the entire device. [资料来源:https://www.doc163.com]

一 柔性复合管生产装置设计主要参数

金属软管:外径8.75毫米,长度1.2米,内径6.75毫米。

底层复合层:材质为聚醚型聚氨酯,厚度为0.35毫米,

面层:材质为聚酯型聚氨酯,厚度为0.05毫米,中间300毫米处,复合软段聚氨酯。

[版权所有:http://DOC163.com]

目录

一 主要设计参数.....................................................................................................1

二 工艺流程图与设计设备的主要功能.................................................................2

2.1工艺流程图....................................................................................................2

2.2设备的布置图................................................................................................2

三 成型工艺参数计算.............................................................................................3 [来源:http://www.doc163.com]

四 成型系统设计计算.............................................................................................4

4.1材料材质特性................................................................................................4

4.2挤出机形式的确定........................................................................................4

4.2.1口模的设计计算.........................................................................................4

4.2.2芯棒的设计计算.....................................................................................5

4.2.3过滤板出口处直径D0的确定................................................................5

4.2.4过滤板和过滤网的设计计算.................................................................5

4.2.5机头及料筒装配尺寸的选取.................................................................6

4.3具加热系统设计及计算................................................................................6

[来源:http://Doc163.com]

五 冷却系统设计.....................................................................................................8

5.1冷却装置的设定............................................................................................8

5.2冷却装置装配尺寸的确定............................................................................8

六 牵引系统设计....................................................................................................9

6.1电动机的选择...............................................................................................9

6.2减速器各数据的计算及确定.......................................................................9

6.3联轴器的选择...............................................................................................11

6.4皮带轮的选择...............................................................................................12

6.5轴、轴承的选择...........................................................................................12

6.6通风管的设计计算..............................................................................14

七 支架设计............................................................................................................16

7.1螺钉的校核...................................................................................................16

7.2支撑板的校核...............................................................................................16

结论............................................................................................................................17

参考文献....................................................................................................................18

致谢............................................................................................................................20

[资料来源:www.doc163.com]

上一篇:电火花放电制备金属纳米颗粒工艺研究(含CAD零件图装配图)

下一篇:安全阀测试系统设计(含CAD图)