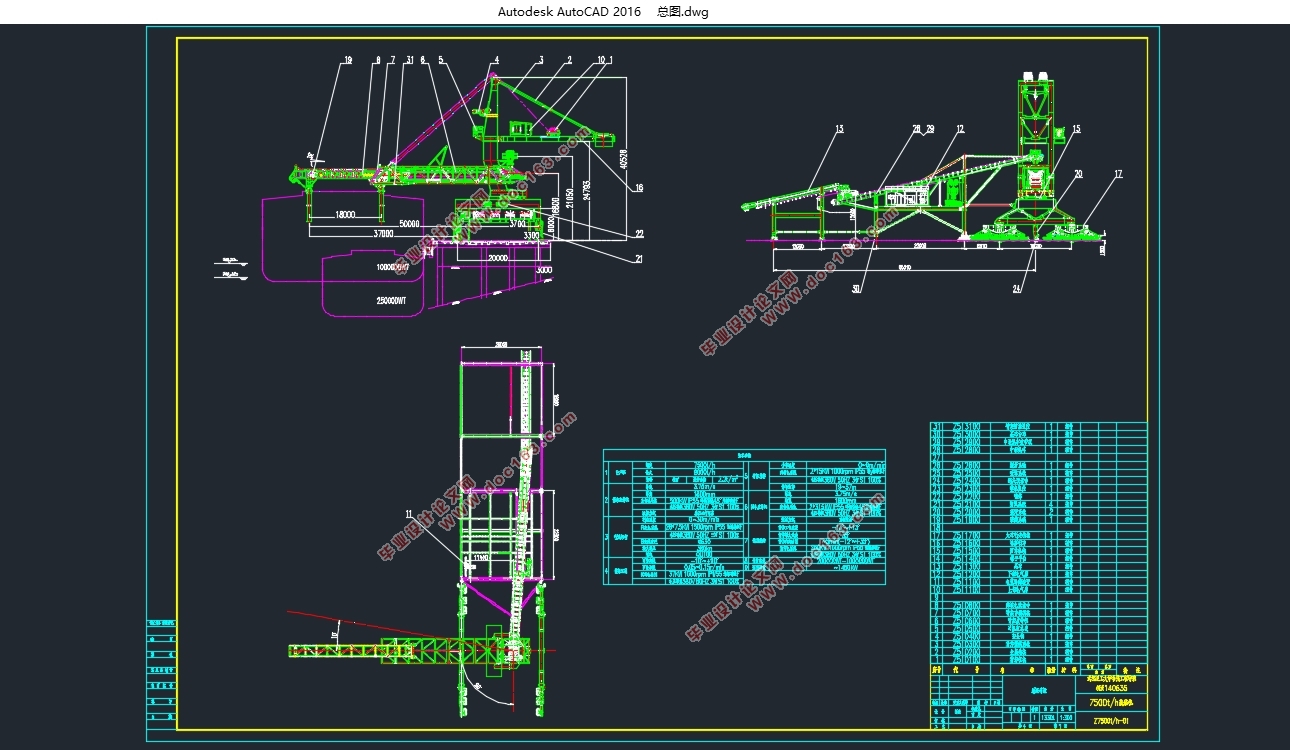

7500t/h装船机总体设计及回转机构设计(含CAD零件图装配图)

7500t/h装船机总体设计及回转机构设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书13000字,CAD图4张)

摘要

本次毕业设计根据港口机械的相关知识,对7500t/h装船机进行了总体设计和回转机构的设计。在总体设计中,首先完成了各类载荷的计算并进行了载荷组合,其次完成了对装船机轮压的计算及校核,最后,根据计算的载荷来检查抗倾覆性和抗风防滑稳定性。

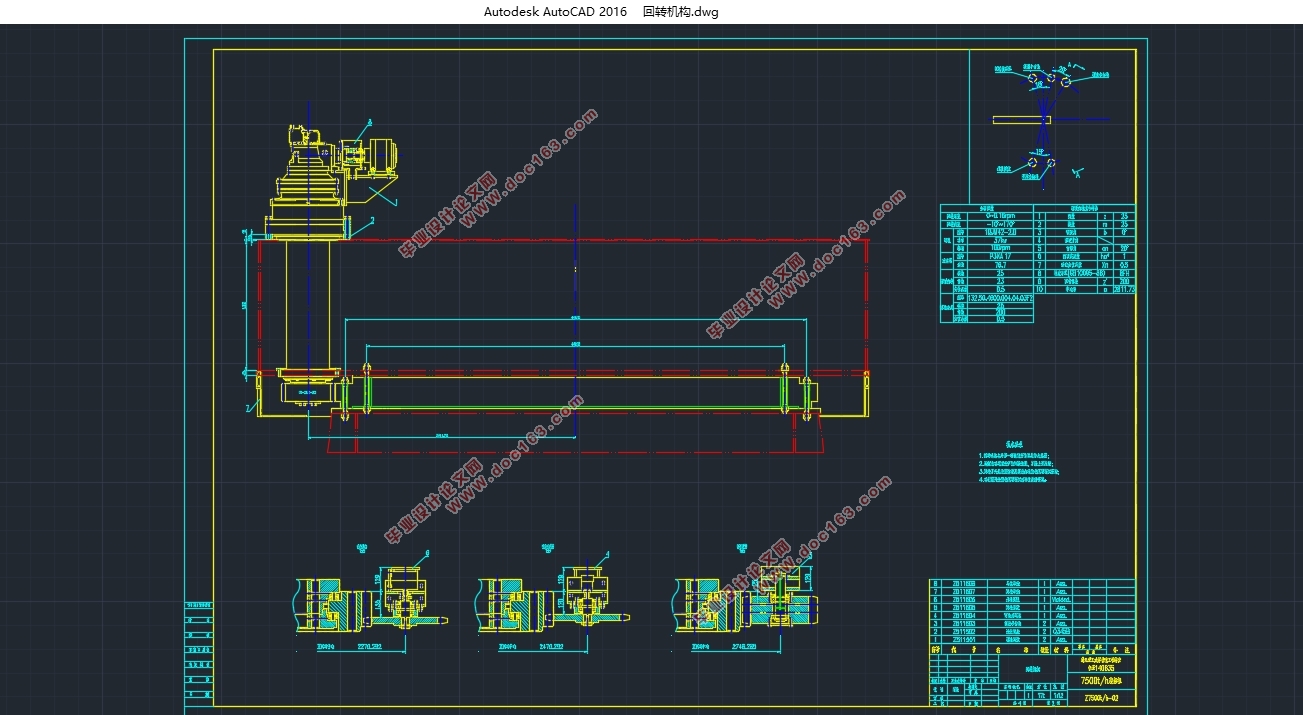

回转机构的设计分为两部分,一是回转支承装置的设计计算,二是回转驱动装置的设计计算。根据计算所得载荷及力矩选取了回转支承装置和液压马达,再根据实际工况设计液压传动回路,选取液压泵等相关液压元件,确定传动比选择减速箱,最后根据实际尺寸完成回转机构的整体布置。

本文的特色是利用液压传动的方式来驱动回转机构的运行。所设计的液压回路同样也适用于其他大型机械的回转机构,具有一般普遍性。

关键词:装船机;载荷计算;回转机构;液压传动

Abstract

This graduation project designed the 7500t/h ship loading machine based on the relevant knowledge of port machinery. In the overall design, the calculation of all kinds of loads was first completed and the load combination was completed. Then, the calculation and verification of the wheel pressure of the ship loader was completed. Finally, the stability against load and non-slip stability were checked. [资料来源:http://www.doc163.com]

The design of the slewing mechanism is divided into two parts. One is the design calculation of the slewing bearing device, and the other is the design calculation of the slewing drive device. The slewing bearing device and hydraulic motor are selected according to the calculated load and torque, and the hydraulic transmission circuit is designed according to the actual working conditions. Hydraulic components such as hydraulic pump are selected .Then to determine the gear ratio and the gearbox is selected. Finally, the overall layout of the slewing mechanism is completed according to the actual size.

The feature of this article is to use hydraulic transmission to drive the rotation mechanism. The designed hydraulic circuit is also applicable to the slewing mechanism of other large-scale machinery, and it has general universality.

Key Words: ship loader;load calculation;slewing mechanism;hydraulic transmission

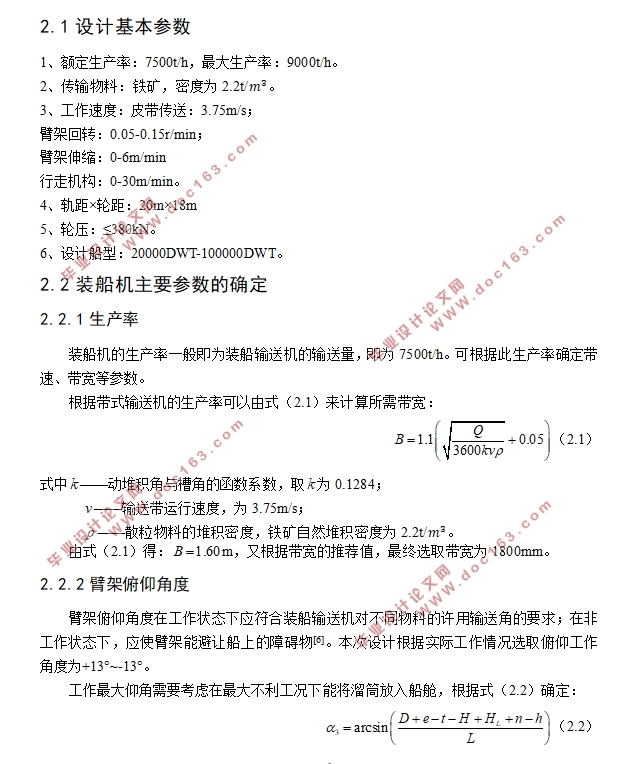

2.1设计基本参数

1、额定生产率:7500t/h,最大生产率:9000t/h。 [来源:http://www.doc163.com]

2、传输物料:铁矿,密度为2.2t/m^3。

3、工作速度:皮带传送:3.75m/s;

臂架回转:0.05-0.15r/min;

臂架伸缩:0-6m/min

行走机构:0-30m/min。

4、轨距×轮距:20m×18m

5、轮压:≤380kN。

6、设计船型:20000DWT-100000DWT。

目录

[资料来源:Doc163.com]

第1章绪论 1

1.1装船机简述 1

1.2装船机的分类 1

1.3装船机发展趋势 1

第2章总体设计 3

2.1设计基本参数 3

2.2装船机主要参数的确定 3

2.2.1生产率 3

2.2.2臂架俯仰角度 3

2.2.3臂架下铰点高度 4

2.2.4臂架卸料点最大幅度 4

2.2.5臂架和溜筒的伸缩距离 5

2.2.6机构工作级别 5

2.3载荷的计算 5

2.3.1自重载荷 5

2.3.2物料载荷 5

2.3.3积垢载荷 5

2.3.4风载荷 7

2.3.5惯性载荷 9

2.3.5大车运行偏斜侧向力 10

2.4轮压校核 11

2.4.1支承反力计算 11

2.4.2轮压计算 12

2.5抗倾覆稳定性验算 13 [版权所有:http://DOC163.com]

2.5.1基本稳定性校核 14

2.5.2动态稳定性校核 14

2.5.2最大风载荷稳定性校核 15

2.6抗风防滑安全性验算 15

2.6.1正常工作状态 15

2.6.2非工作状态 15

第3章回转部分设计 17

3.1回转支承装置 17

3.1.1回转支承装置的型式 17

3.1.2回转支承装置的计算载荷 17

3.1.3回转支承装置的计算载荷组合 19

3.1.4回转支承装置的计算 20

3.2回转驱动装置 22

3.2.1回转驱动装置的传动形式 22

3.2.2回转驱动装置的计算 22

3.2.3回转液压系统主要参数的确定 23

3.2.4液压系统原理图的拟定 24

3.2.5液压元件的计算与选择 25

3.2.4减速器的选择 26

3.2.4联轴器的选择 27

第4章环境影响与经济性分析 28

4.1环境影响分析 28

4.2经济性分析 28

第5章总结与展望 29

5.1总结 29

5.2展望 30

参考文献 31

致谢 32

上一篇:磁悬浮轨道廊式接驳系统设计(含CAD图,SolidWorks三维图)

下一篇:输入输出可控的液压系统蓄能器设计(含CAD零件图装配图,CATIA三维图)