Prusa i3型3D打印机设计(含CAD零件图装配图)

Prusa i3型3D打印机设计(含CAD零件图装配图)(论文说明书9200字,外文翻译,CAD图8张)

摘 要

随着工业技术的发展,传统的加工方式已经很难满足现代加工的需求,于是

一种全新的制造技术-3D打印技术应运而生。经过3D打印技术制造完成的零部件,完全真实的再现三维造型,无论外表面的曲面还是异形孔,都可以真实准确的完成造型,不再需要再借助外部设备进行修复。

随着3D打印技术在市场的应用越来越深入和广泛,3D打印机的需求越来越大,因此,论文旨在设计一种桌面级3D打印机。

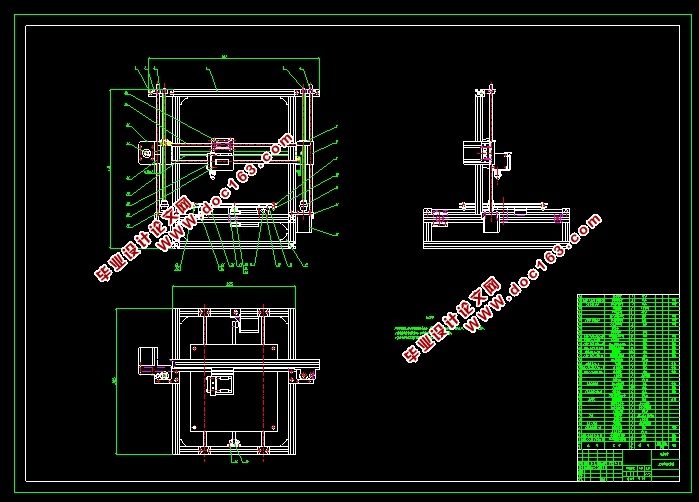

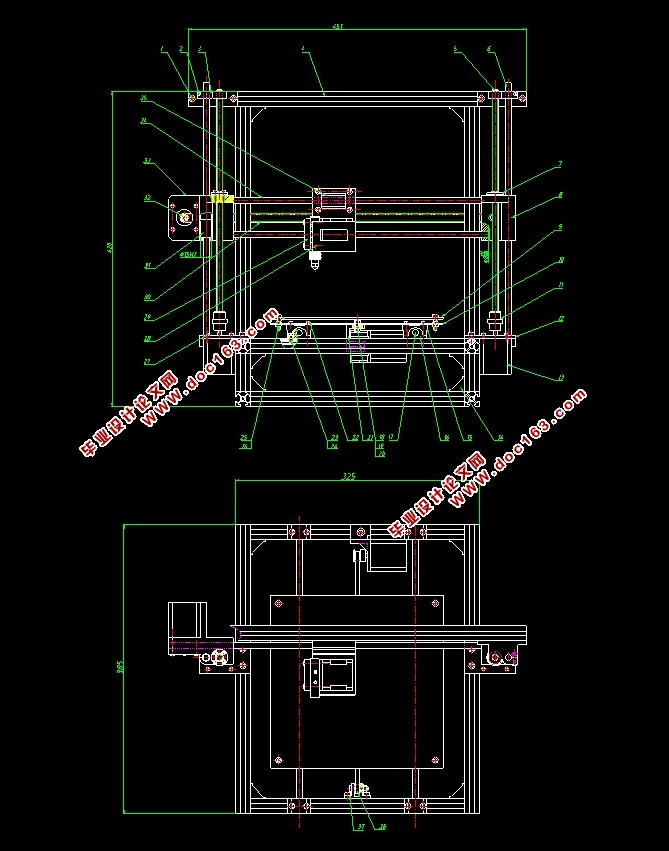

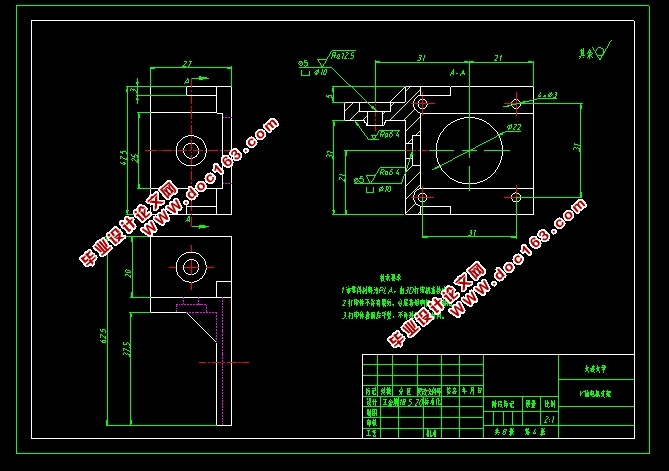

本次设计主要是对3D打印机的机械结构进行设计以及一些必要的设计计算,通过对打印喷头以及x-y轴打印平台的分析,选择适当的材料以及参数,通过solidworks的绘图对设计产品进行3D构图,最后完成装配。最终要求3D打印机在打印过程中,运动和传动平稳,使其稳定生产。

关键词:3D打印技术;x-y轴打印平台;打印喷头

ABSTRACT

With the development of industrial technology, traditional processing methods are hard to meet the needs of modern processing. A new manufacturing technology -3D printing technology came into being. The parts made by 3D printing technology are completely reproduced in three-dimensional modeling. No matter the surface of the surface or the shaped hole, it is true and accurate to complete the modeling, and no longer need to be repaired with the aid of the external equipment. [资料来源:https://www.doc163.com]

With the more and more in-depth and extensive application of 3D printing technology in the market, the demand for 3D printers is becoming more and more large. Therefore, the paper aims to design a desktop 3D printer.

The design is mainly designed for the mechanical structure of the 3D printer and some necessary design and calculation. Through the analysis of the printing nozzle and the X-Y axis printing platform, the appropriate materials and parameters are selected. The design of the product is made by the SolidWorks drawing, and the assembly is finished at the end. Ultimately, 3D printer needs to be stable in movement and transmission during printing.

Keywords: 3D printing technology; X-Y axis printing platform; Print nozzle

主要设计方面

(1) Y轴(打印截面平面)运动机构

(2) 轴(截面累积)运动机构

(3) 挤出机(耗材挤出)机构

(4) 框架设计

通过以上四个主要机械结构,构成3D打印机的基本运动结构,可以初步实现3D打印的打印过程。

1.5.2 设计参数 [版权所有:http://DOC163.com]

成 型 空 间 :210mm*210mm*220mm

最大移动速度:50mm/s

喷头定位精度:0.05mm

最大成型质量:500g

[资料来源:http://doc163.com]

目录

摘 要 I [资料来源:www.doc163.com]

ABSTRACT II

目录 III

引 言 1

1.绪 论 2

2.总体设计方案选择 6

3.机械结构设计计算 12

4.传感器选择 24

结论 26

参考文献 27

致谢 28

附录1 外文译文 29

附录2 外文原文 34

[来源:http://www.doc163.com]

上一篇:DL32M斜床身数控机床尾座结构设计(含CAD零件装配图,SolidWorks三维图)

下一篇:SP100-2型自动装药机设计(含CAD零件图装配图)