小型荞麦播种机动力,传动,行走及功能转换机构的设计

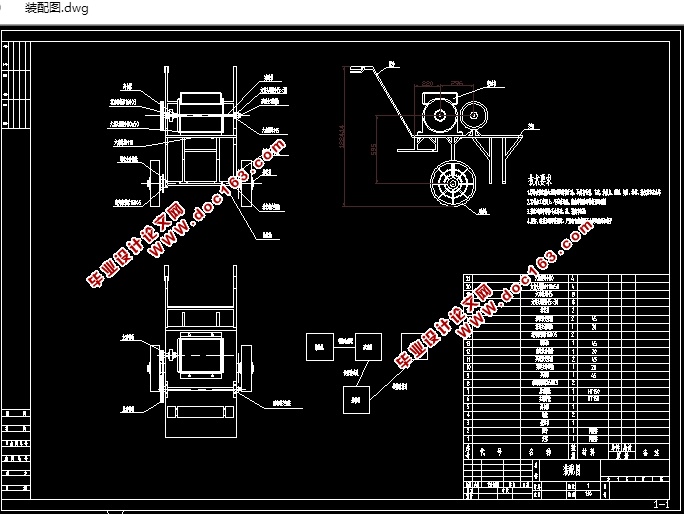

小型荞麦播种机动力,传动,行走及功能转换机构的设计(含CAD零件图装配图)(任务书,文献综述,论文说明书10000字,CAD图纸7张)

摘 要

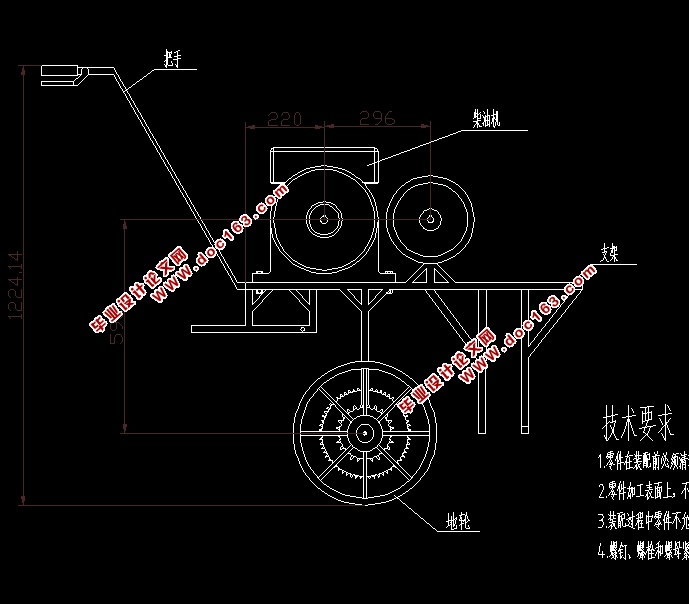

小型荞麦播种机是对荞麦进行播种作业的农业机械。现在荞麦的营养价值等愈发受到人们的重视,发展前景广阔,所以荞麦的播种和收获等非常重要。本文设计了小型荞麦播种机的行走、传动及功能转换机构。播种机提高了农民的劳动效率,解放劳动力,并且符合现在科技发展与机械化的趋势。

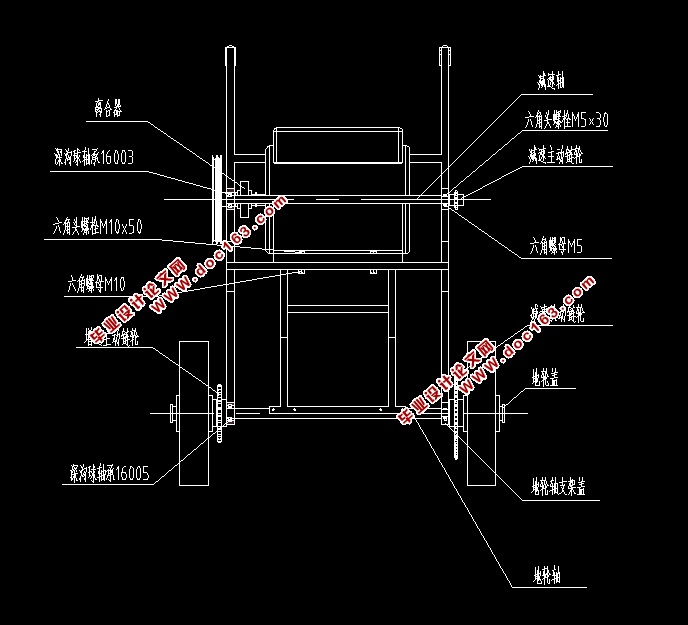

本文首先概述了播种机械的现状、分类、要求和发展,同时详细叙述了荞麦播种机的传动和行走机构设计以及相关零部件的设计,包括播种机的动力源选择、机械传动的种类选择以及尺寸、相关轴的设计等。该播种机以小型柴油机作为动力源,通过传动机构带动行走机构及排种器等运动。设计在考虑传动结构合理的同时兼顾了结构简单,生产及维护方便、效率较高、损耗少、操作方便等目的。

关键词:播种机 行走 传动 机构

Abstrict

mini buckwheat sower is a machine of sowing buckwheat seeds. Recently, the buckwheat has been attached importance to its nutrition, which brings a bright prospect.Therefore, the sowing and harvist of it become highly important. In this essay, structure of the moving ability,transmission and mode switch of this sower was designed in order to gain the productivity. Further, the decrease of using human resource through this machine also accord with the trendency of mechanization in agriturae.

[版权所有:http://DOC163.com]

This essay will illustrate the actuality,classification, modern requirments and developments of the seed planting machine. Moreover, the details of the structure of transmission and the design of moving will be expained including the choosing of power sources, mechanical transmission, size and the bearings excogitation. This sower will use diesel engine as power souse and moving through driving of transmission part, which finally make seed-metering device and running mechanism move. in this design, the reasonability of samplised structure was considered which will lead to the simplify of prudusing and reparing. Also, the efficiency,attrition and user-friendly control will also be considered in the disign of this machine.

Key words: sower moving transmission mechanism

[资料来源:http://Doc163.com]

目 录

摘 要………………………………………………………………………………Ⅰ

[资料来源:http://Doc163.com]

Abstract……………………………………………………………………………Ⅱ

第1章 引言………………………………………………………………………1

第2章 播种机概述………………………………………………………………2

2.1播种机现状……………………………………………………………2

2.2播种机分类……………………………………………………………4

[资料来源:http://doc163.com]

2.3播种机发展趋势………………………………………………………5

第3章 小型荞麦播种机的设计计算……………………………………………6

3.1总体传动设计方案的选择确定………………………………………6

3.2工作阻力的确定………………………………………………………8

3.3工作速度的确定………………………………………………………8 [版权所有:http://DOC163.com]

3.4驱动功率的确定………………………………………………………8

3.5地轮的转速……………………………………………………………9

3.6传动比的确定…………………………………………………………9

第4章 链传动的设计……………………………………………………………10

4.1地轮与排种器之间的链传动…………………………………………10 [资料来源:https://www.doc163.com]

4.2地轮与减速轴之间的链传动…………………………………………14

第5章 带传动的设计……………………………………………………………19

第6章 链轮的设计………………………………………………………………22

6.1链轮的材料选择………………………………………………………22

6.2地轮与减速轴之间主动链轮的设计…………………………………22 [来源:http://Doc163.com]

6.2地轮与减速轴之间从动链轮的设计…………………………………23

6.3地轮与种箱之间主动链轮的设计……………………………………24

6.4地轮与种箱之间从动链轮的设计……………………………………25

第7章 带轮的设计………………………………………………………………25

7.1带轮的材料选择………………………………………………………25

7.2主动带轮的设计………………………………………………………26 [资料来源:www.doc163.com]

7.3从动带轮的设计………………………………………………………26

第8章 链轮的设计………………………………………………………………27

8.1初步确定轴的最小直径………………………………………………27

8.2减速轴的结构设计……………………………………………………28

8.3地轮轴的结构设计……………………………………………………28 [资料来源:http://Doc163.com]

第9章 支架、扶手与轴承等选择设计及功能切换……………………………29

9.1支架设计………………………………………………………………29

9.2把手设计………………………………………………………………30

9.3轴承选择………………………………………………………………31

9.4功能切换………………………………………………………………31 [资料来源:http://Doc163.com]

第10章 三维建模及装配…………………………………………………………31

结语…………………………………………………………………………………34

致谢…………………………………………………………………………………35

参考文献……………………………………………………………………………36