立式煤仓疏通装置设计(含CAD零件图装配图)

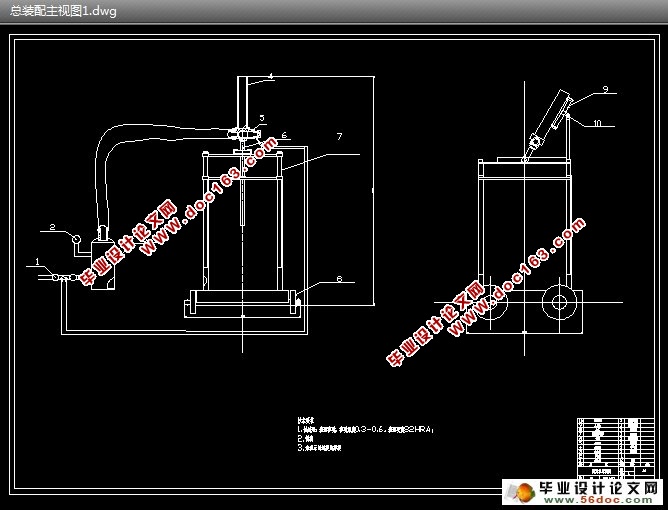

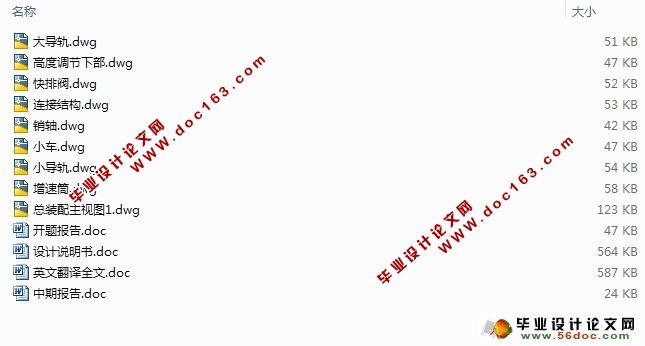

立式煤仓疏通装置设计(含CAD零件图装配图)(开题报告,中期报告,设计说明书13800字,外文翻译,CAD图7张)

摘 要

本文首先说明了国内外煤仓疏通的现状,现代化生产都是以自动化流水形式为代表,而其组成大部分都是输送环节,没有可靠的输送环节自动流水作业的效率就会大打折扣。目前,在煤炭行业中所设置的煤仓成为联系井上下各个生产环节的重要枢纽,原煤多是由煤仓经锥形漏斗依靠自重流动输送。在输送过程中出现的煤仓堵塞现象已经成为各煤矿所面临的普遍性难题,严重影响了原煤的输送、制约着生产效率,并且存在极大的安全隐患。

由此,本文发现了研究出一种便捷高效的疏通装置对企业安全及高效生产的重要性,本文在了解国内外煤矿有关疏通现状的基础上,对疏通机的工作原理进行了详细的研究,并查阅相关资料利用自己所学的知识对疏通机的设计提出了自己的观点和设计过程,由于作者能力有限文中不免有不妥之处,请各位老师给以指导和批评.

关键词: 煤仓堵塞 疏通机 输送效率

Abstract

This paper describes the current situation about clearing the coal bunker at home and abroad, a modern production is represented by an automated pipeline, which is most consisted of transport links. The efficiency of transport links will be greatly reduced without reliable automatic assembly-line. At present, the coal bunker becomes an important hub for the various production processes. Coal flows through conical hopper by gravity, while the bunker clogging occurred in the course of transmission has become a universally problem faced by every coal mine which seriously affects the delivery of coal and restrict the production efficiency and there’s also a great security risk. [来源:http://Doc163.com]

Thus, we developed a convenient and efficient device for clearing. The paper carried out a detailed study on working principles based on the understanding about the status of mine at home and abroad. Through accessing to the relevant information and using the learned knowledge, I put forward my views and the design process. Since the limited ability of author, there’s inevitably something wrong of the paper, please give guidance and criticism.

Key words: coal bunker jam; clear machine; Transmission efficien

[资料来源:http://www.doc163.com]

目录

目录 i

摘 要 I

前 言 1

1概况 2

2煤仓堵塞机理及改善煤仓通畅性的措施 3

2.1煤仓堵塞机理 3

2.2改善煤仓通畅性的措施 7

3. 煤仓疏通方案的确定 9

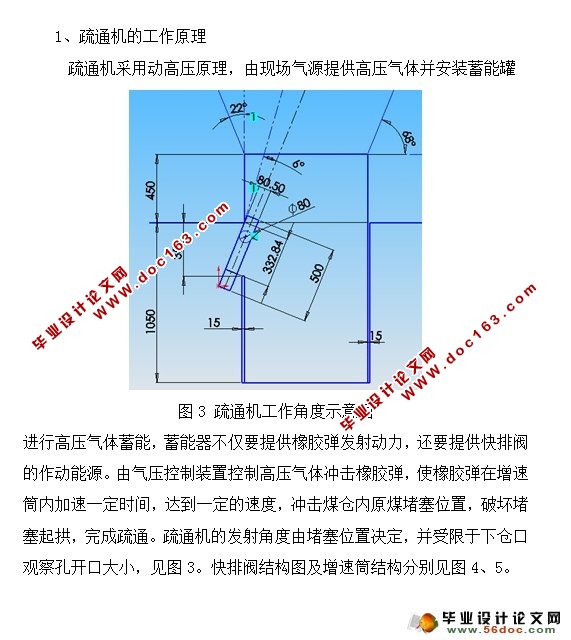

4、疏通机的工作原理 10

5疏通机的设计计算 14

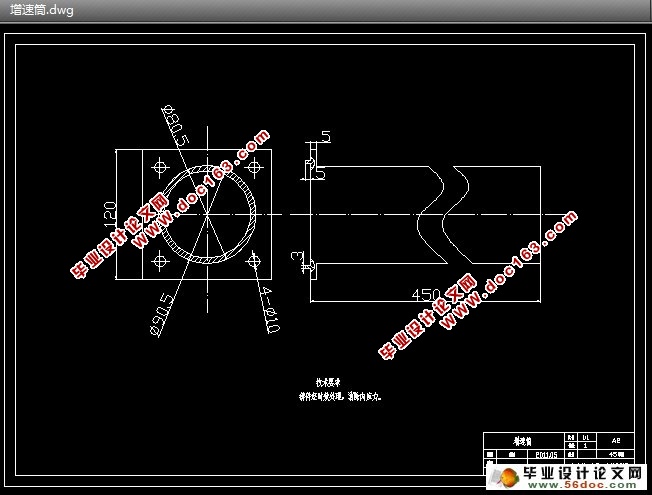

5.1增速及缓冲装置 14

5.1.1橡胶弹和增速筒的设计计算 14

5.1.2缓冲装置 17

5.2角度调节装置 18

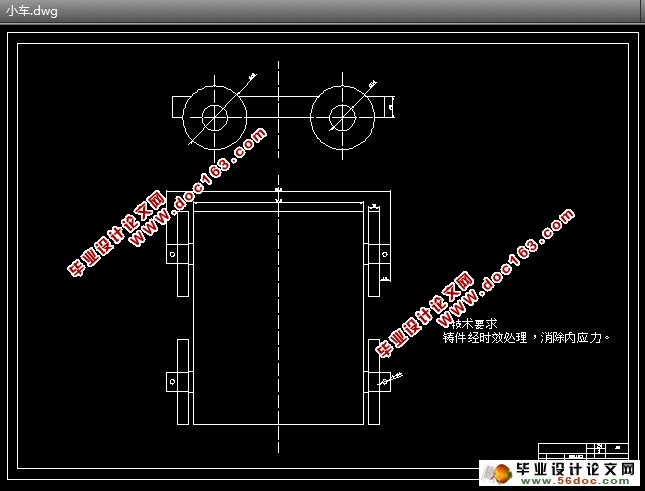

5.3高度调节及底座装置 18

5.3.1高度调节装置 19

5.3.2底座 20

5.4压力表 20

5.4.1压力表的分类 21

(1)压力表按其测量精确度 21

(3)压力表按其测量范围 22

(4)压力表按其显示方式分 22

5.5蓄能装置 25

[资料来源:http://www.doc163.com]

5.6进气总阀和储气罐进气阀 26

5.7控制发射装置 27

5.7.1控制装置 27

5.7.2快排阀 27

5.8法兰结构及密封件选用 28

6 创新点 30

7 使用与维护 31

致谢 32

参考文献 33 [来源:http://www.doc163.com]

上一篇:CA6140车床滤油器体的设计

下一篇:汽车变速箱前后面孔系钻削攻丝组合机床设计(含CAD零件图装配图)