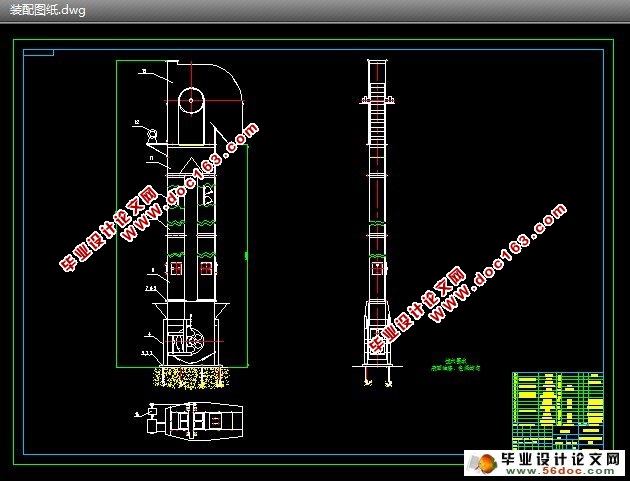

斗式提升机总体及机座部分设计(含CAD零件图和装配图)

斗式提升机总体及机座部分设计(含CAD零件图和装配图)(任务书,论文说明书10500字,CAD图11张,答辩PPT)

摘 要

关键词:1。TDTG50/24斗式提机由机头、机座、机筒、观验机筒、减压机筒、畚斗、畚斗胶带、传动装置等部分组成。

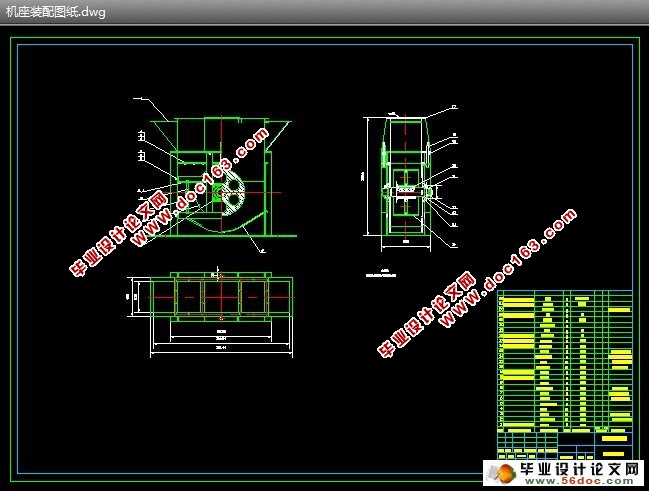

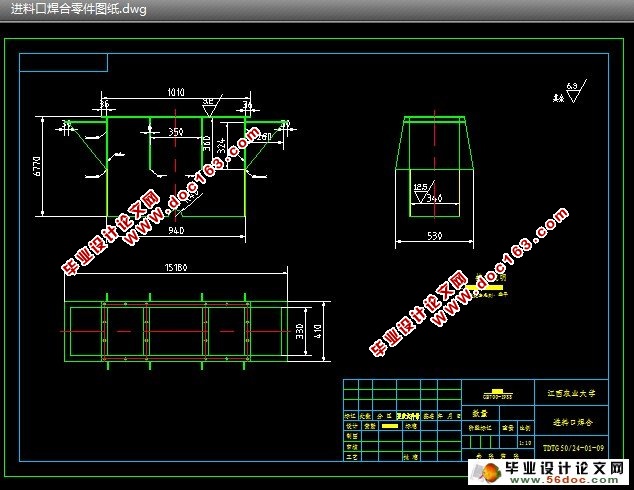

2。机座部件由机座体、底轮、底轮轴、张紧装置、进料斗等部分组成。机座体设有顺向和逆向进料口,可根据用户需要将进料斗安装在任一位置;张紧装置供调整正头、底轮的相对位置并张紧畚斗带以防其偏摆和打滑;机座体下两侧各设一排插门,可供清理杂物。

3。 机座结构方案及总体布置

斗式提升机尾轮安装在机座内部,由于斗式提升机在实际长时间运行过程中可能会出现带松动的现象,因此必须设置带张紧装置,以便在情况变化时立即做出相应的调整。因此通过设置机座两边的调节丝杆来调节底轮的位置来调节带的松动或张紧。另外为使物料不在机座底部残留机座体下部两侧各设一排料插门,可供及时清除机内余粮和杂物。以便在提升不同的物料时留下不便。其底轮和底轮轴安装在机座下面的机箱里面并通过调节丝杆来固定其位置。进料口部分焊接在机座体上,进料口最下面部分套装在机箱里面,机箱底部用于存放进料口留进的物料。机箱中央最上边分别焊接一个三角肋板,调节丝杠通过机架上面的通孔连接到机箱的三角肋板上,调节丝杠连接到机箱的一端用钢丝锁紧,另外在丝杠上安装一螺纹锁套来固定机箱的位置,也就是控制机箱整体的上下移动。机箱两边分别安装两个定位环和定位套来防止机箱两边摆动。其总体布置见图纸。

[资料来源:http://www.doc163.com]

机座机架由角钢焊接而成,其一边可拆,另一边焊接牢固。机箱也由钢板焊接成型。其一边切割掉一圆板,用于安装带轮和带轮轴,安装好后用盖板锁紧而密封。当带轮与轴安装进入机箱后轴两边端部安装轴承安装板和轴承最后将其密封。进料口部分也由钢板咬边后焊而成,进料部分最上面用于安装机筒,与机筒采用法兰连接。

除机内余粮和杂物。

Abstract

The lifting machine is one of the large-scale regular machine,used in the rise or fall and transport of various kinds of heavy objects. The small-scale lifting machine plays an important role too in daily life.

TDTG50/24 lifting machine is made up of the head ,the middle one and motor,decelerator.It links by the shafts.The motor is the power source,the decelerator is a transmission,the cylinder,in order to carry out and control some,among then,the design of each part.

The floor one is made up by the finally segment , the hat ,the pulley ,the finally shaft,and the bearing .There are two ways to carrying-in things,one is the right way,the other is the opposite way.You could choose one way with your need.The force part is used to adjust the position of the head shaft and the finally shaft .There is a row of windows in order to clean the rubbish. [资料来源:http://Doc163.com]

The finally part of the lifting machine is put inside.Maybe the force will decrease ,so it should have a force part,which can adjust itself .Besides,to keep the rubbish out the machine ,there are a row of windows,so it has a clean environment Its pulley and shaft put in a box.The part of carrying-in things is fixed in the box too.The middle part of the box contacts a floor .

The common one dose not have the check one,and it looks like the above one .The part which lets down the press.It can make the air as a cycle .

The motor usually takes a decelerator..(the flexible coupling and the transport).It works by the shaft or by the common motor and decelerator .Both of the two motors(or decelerator)should put at the fixture,if the height is less 10 m it also could put at the basic floor part of the lifting machine .

Key words:the lift machine, the finally part,TDTG50/24.

型号含义:

TDTG50/24 T、专业代号: 通用设备 [资料来源:http://doc163.com]

DT、产品品种代号: 表示“斗提”二字汉语拼音首写字母

G、产品类型代号: 固定式

50/24、产品主要规格: 头轮直径500mm,畚斗宽度240mm

[资料来源:http://Doc163.com]

目 录 [资料来源:https://www.doc163.com]

第一部分 绪论

1.1 斗式提升机简介……………………………………………………… (4)

1.2 斗式提升机的主要特点……………………………………………… (4)

1.3 斗式提升机输送工作原理…………………………………………… (4)

1.4 机座简介…………………………………………………………… (5)

第二部分 机构方案及总体设计……………………………………………… (5)

[资料来源:https://www.doc163.com]

第三部分 设计计算…………………………………………………………… (7)

3.1 3.1.1 主要技术参数……………………………………………… (7)

3. 1.2 输送量计算………………………………………………… (7)

3. 1.3电动机功率的计算及电动机选择…………………………… (8)

3.2 带传动设计…………………………………………………………… (8)

3. 2.1 带的选择………………………………………………………… (8)

3. 2.2 带轮………………………………………………………………(9)

3.3 畚斗选择及在平带上的固定方式………………………………… (9)

3.4 斗式提升机的装料…………………………………………………… (10)

3.5 轴的强度计算…………………………………………………………(12)

3. 5.1 按扭转强度条件计算轴的直径………………………………… (12)

3. 5.2 零件的轴向定位…………………………………………………(12)

3.5.3 轴的校核…………………………………………………………(12)

3.6 带轮与轴的配合方式……………………………………………………(12)

3.6.1 键的选用步骤……………………………………………………… (12)

3. 6.2 平键联接的强度计算………………………………………………(12)

[资料来源:www.doc163.com]

3.7 轴承的选择………………………………………………………………(13)

3.8 机座的固定……………………………………………………………… (14)

第四部分 安 装 、操作与 保养……………………………………………… (15)

参考文献…………………………………………………………………………… (17)

致谢……………………………………………………………………………… (18) [来源:http://Doc163.com]

上一篇:斗式提升机机头及中间节设计(含CAD零件图和装配图)