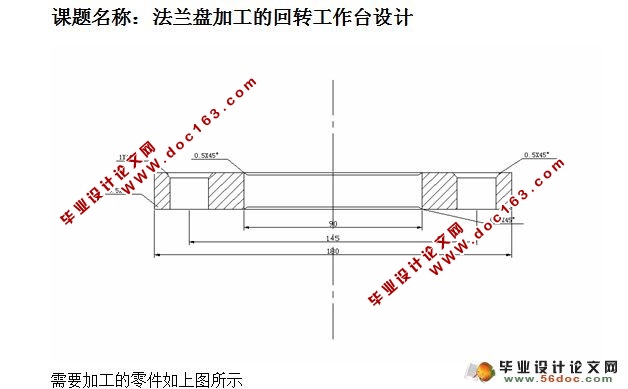

法兰盘加工的回转工作台设计

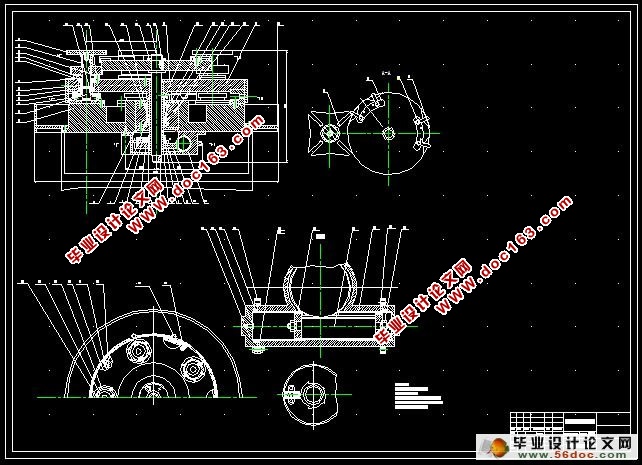

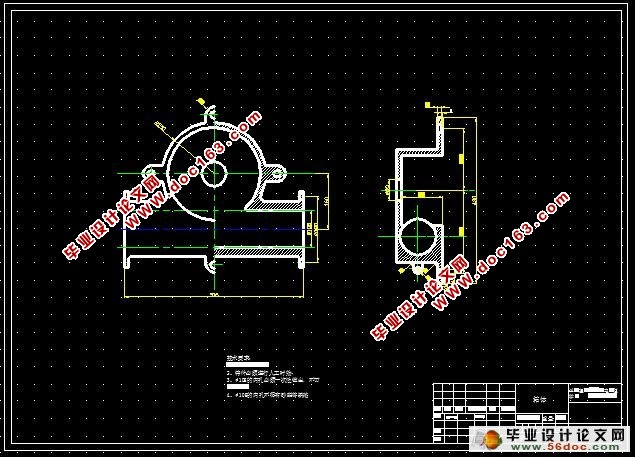

法兰盘加工的回转工作台设计(开题报告,设计说明书11700字,CAD图纸5张)

中文摘要:

法兰盘为一个式厂常用件,加工精度要求不太高,但年需求量较大。因此,加工此法兰盘时,首先,需要考虑的问题就是加工的生产效率。

1、采用通用机床夹加工此法兰盘时,加工的范围可以进行扩大,可以加工出一系列的法兰盘,但通用机床的调整时间较长,装央与拆卸工件的时间较工,使得法兰盘的加工效率无法进行提高。

2、专门化机床的工艺范围较窄,只能加工一尺寸范围内的某一类零件,完成某一种特定工序,但生产效率较通用的机床高。

3、专用机床的工艺范围最窄,通常只能完成某一特定零件的特定工序,但专用机床的加工效率是这三类机床中最高的。因此专用机床较为适用了加工此类法兰盘。

4、组合机床作为专用机床中的一种与通用机床的专门化机床相比较。

英文摘要:

So the flange plate is type factory commonly used, the processingprecision request not too high, but the year demand quantity isbigger.

Therefore, processes time this flange plate, first, needs to considerthe question is the processing production efficiency.

[资料来源:https://www.doc163.com]

1. uses when the general engine bed clamps processes this flangeplate, the processing scope may carry on the expansion, may process aseries of flange plates, but the general engine bed time is longer,installs Yang Yu to disassemble the work piece the time to compare thelabor, causes the flange plate the processing efficiency to be unableto carry on the enhancement.

2. specialized engine bed craft scope narrower, only can process ina size scope some kind of components, completes some specific workingprocedure, but a production efficiency more general engine bed ishigh.

3. the special purpose machine craft scope is narrowest, usuallyonly can complete some specific components the specific workingprocedure, but the special purpose machine processing efficiency is inthese three kind of engine beds highest. Therefore the special purposemachine was suitable has processed this kind of flange plate.

英文关键词:The flange plate, uses the general engine bed to clamp, specializedengine bed, rotary table [资料来源:Doc163.com]

[版权所有:http://DOC163.com]

目 录

一.毕业设计的目的………………………………………………3

二.加工零件的分析………………………………………………

三.加工工艺的编排与分析………………………………………

四.结构设计………………………………………………………

五.各部件的计算与校核…………………………………………

六.整体的液压设计………………………………………………

七.整体的电气控制设计………………………………………… [版权所有:http://DOC163.com]

八.毕业设计总结…………………………………………………

九.主要参考资料…………………………………………………

[资料来源:http://doc163.com]

上一篇:重型桶装成品搬运堆垛系统机构(搬运机器人机器手)设计

下一篇:快速成型机的设计