Z3050摇臂钻床壳体的机械加工工艺及工装设备(含工序卡)

Z3050摇臂钻床壳体的机械加工工艺及工装设备(含工序卡)(包含任务书,论文说明书14000字,7张cad,工序卡)

摘要

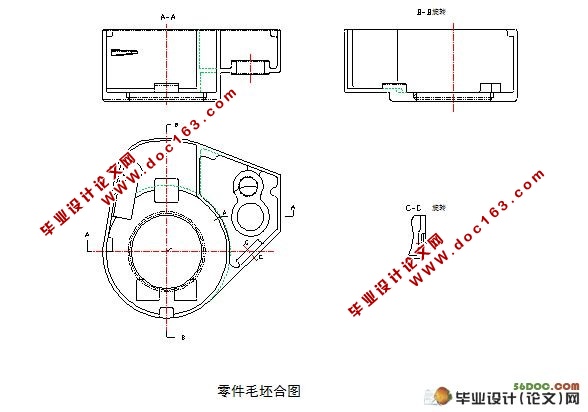

壳体的加工质量将直接影响机器的性能和使用寿命。本次设计旨在提高Z3050摇臂钻床壳体的加工效率,由此我们首先对壳体的结构特征和工艺进行了仔细的分析,然后确定了一套合理的加工方案,加工方案要求简单,操作方便,并能保证零件的加工质量。在制定加工工艺规程的顺序如下:

1分析被加工零件;

2选择毛坯;

3设计工艺过程:包括划分工艺过程的组成,选择定位基准,选择零件表面的加工方法,安排加工顺序等;

4工序设计:包括选择机床和工艺装备,确定加工余量,计算工序尺寸及其公差,确定切削用量及计算工时等;

5编制工艺文件。

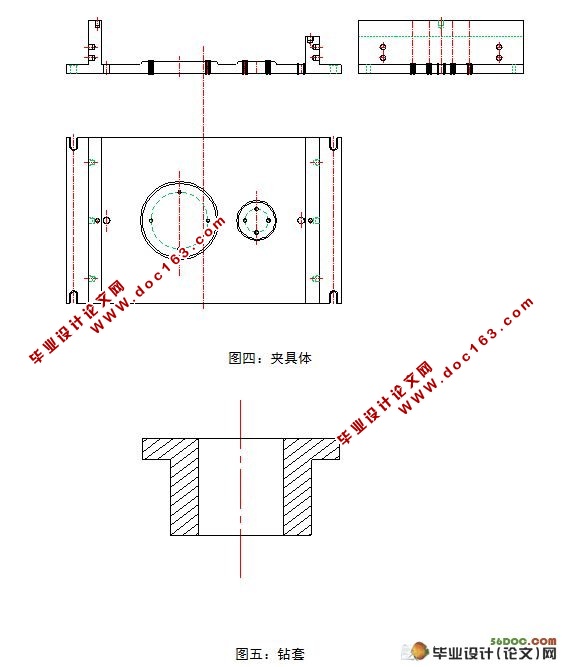

此外,为了提高劳动生产率,降低劳动强度,保证加工质量,需设计专用夹具,本次设计选择了第八道工序钻5- 17,M48,M16的夹具设计,以满足加工过程的需要。

关键词:壳体; 工艺规程; 夹具

Abstract: The shell processing quality directly will affect the machine the performance and the service life. This design is for the purpose of enhancing the Z3050 radial drill drilling machine shell the processing efficiency, first has carried on the careful analysis from this us to the shell structure characteristic and the craft, then had determined set of reasonable processings plans, the processing plan request are simple, the ease of operation, and can guarantee the components the processing quality. In formulation processing technological process order as follows: [资料来源:www.doc163.com]

1 analysis is processed the components;

2 choices semifinished materials;

3 designs technological process: Including division technological process composition, preferred orientation datum, choice components surface processing method, arrangement processing order and so on;

4 working procedures designs: Including chooses the engine bed and the craft equipment, the determination processing remainder, the computation working procedure size and its the common difference, the determination cutting specifications and the computation man-hour and so on;

5 establishments technological document.

In addition, in order to enhance the labor productivity, reduces the labor intensity, guaranteed the processing quality, must design the unit clamp, this design chose the eighth working procedure to drill 5- 17, M48, the M16 jig design, by satisfied the processing process the need.

Key word: Shell; technological process;

本次设计是提高Z3050摇臂钻床壳体的加工效率,适应壳体镗面和加工孔的要求,设计正确的加工工艺路线,以及某道工序的夹具。这次设计涉及到机床,机械加工工艺,工装夹具等机制专业的几乎所有的专业基础知识,是一次全面,系统地检查自己在大学期间对专业知识学习的情况,在整个设计过程中做到严谨认真,一丝不苟的精神,尽量使自己的设计达到理想的水平,通过独立的查找资料,分析,计算完成方案设计,图纸设计和编写技术文件等,设计了这套比较完整的加工工艺路线,使自己对机制专业有了更深刻的认识。

[资料来源:Doc163.com]

下一篇:柴油机惰轮A轴进油孔钻夹具设计(CAD图纸和Proe三维造型)☆