一种发动机缸盖单工序加工工艺及其夹具设计(含CAD图,工艺卡,工序卡)

一种发动机缸盖单工序加工工艺及其夹具设计(含CAD图,工艺卡,工序卡)(论文说明书11600字,外文翻译,CAD图纸14张,工艺卡,工序卡)

摘 要

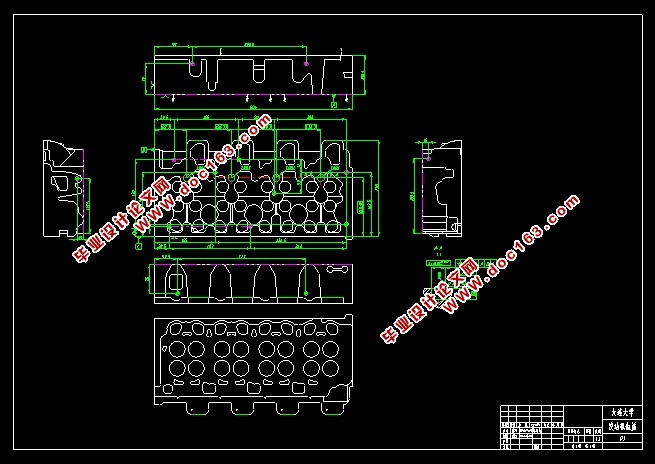

本篇论文的主要内容是完成发动机缸盖的“铣进排气侧面,扩、铰碗型塞片孔”这一工序的加工工艺,以及加工这道工序所需的夹具设计。研究了如何改善传统的加工工艺,减少了工艺的复杂性,简化加工工艺,达到自动化生产。分析零件结构,发现发动机缸盖含有结构复杂,和加工精度的标准要求高的特点,进行加工工艺的优化,确定了加工的工艺路线,使得加工过程简便,达到快速生产的目的。以及“铣进排气侧面,扩、铰碗型塞片孔”这道工序的专用夹具设计,夹具体的作用,其中夹具在设计的过程中需要解决的问题,例如工件加工时是如何定位的,定位基准是如何选择的,夹紧装置是如何选择的,夹具体的主要部分的设计计算,以及夹具体的主要部分在加工该道工序时起到的作用,等。在完成工序分析和夹具设计的过程中,保证自身质量的前提下,采用自动化生产线,专用夹具,数控机床、加工中心,减少了加工的成本,提高了加工效率,保证了生产的均衡性,提高了经济效益。

关键词:自动化生产线;专用夹具;发动机缸盖 [资料来源:http://www.doc163.com]

ABSTRACT

The main content of this paper is to complete the machining process of "Milling intake and exhaust side, expansion, hinge plug hole" of engine cylinder head, as well as the fixture design needed to process this process. This paper studies how to improve the traditional processing technology, reduce the complexity of the process, simplify the processing process, and achieve automatic production. By analyzing the structure of the parts, it is found that the engine cylinder head contains the characteristics of complex structure and high standard requirement of machining precision. The processing technology is optimized and the processing route is determined, which makes the machining process simple and rapid production. As well as the special fixture design of "Milling intake and exhaust side, expansion, hinge bowl plug hole", the specific role of clamps, and the problems that need to be solved in the process of fixture design, such as how to locate the workpiece in the process of processing. How to select the positioning datum, how to select the clamping device, how to design and calculate the main parts of the clamp, and how the main parts of the clamp play a role in the processing of the process, etc. In the process of working procedure analysis and fixture design, the automatic production line, special fixture, numerical control machine tool, machining center are adopted under the premise of ensuring their own quality. The cost of machining is reduced and the processing efficiency is improved. The balance of production is guaranteed and the economic benefit is improved. [资料来源:https://www.doc163.com]

Key words: Automatic production line; Special fixture; Engine cylinder head

零件图分析

设计发动机缸盖某一工序加工工艺规程及该工序的成组夹具。已知:零件材料为灰铸铁HT200,年产量10000件。

缸盖是安装在缸体的上面,从上部密封气缸并构成燃烧室。它经常与高温高压燃气相接触,所以,承受很大的热负荷和机械负荷。发动机缸盖是发动机中最关键的零件之一,其精度要求之高,加工工艺复杂,加工的质量直接影响发动机的整体性能和质量,所以,发动机缸盖的加工尤其重要。

[来源:http://Doc163.com]

目 录

摘 要 I

ABSTRACT II

1 绪论 1

1.1 研究领域 1

1.2 论文(设计)工作的理论意义和研究价值 1 [资料来源:http://www.doc163.com]

1.3 目前研究的概况和发展趋势 1

2 零件图分析 3

2.1 发动机缸盖的结构分析 3

2.2 发动机缸盖的加工工艺路线 4

3 工序设计 7

3.1 工序选择 7

3.2 选择表面加工方法 12

3.3 确定毛坯的尺寸公差和机械加工余量 12

3.4 选择定位基准 13

4 夹具的设计 14

4.1 问题的提出 14

4.2 夹具设计 17

5 夹具的各个部件 21

5.1 定位块 21

5.2 直齿圆柱齿轮 22

5.3 齿条 22

5.4 轴 23

5.5 端盖 23 [来源:http://Doc163.com]

5.6 法兰盘 24

5.7 菱形销 25

5.8 缸体 25

5.9 支座 26

5.10 导向套 26

5.11 其他 27

6 结 论 28

参 考 文 献 29

附录1:外文翻译 30

附录2:外文原文 34

致 谢 42 [来源:http://www.doc163.com]

上一篇:某型汽车汽缸盖顶面半精铣削加工夹具的设计(含CAD零件装配图)

下一篇:后端盖零件编程及夹具设计(含CAD图,IGS,SolidWorks三维图,工艺工序卡)