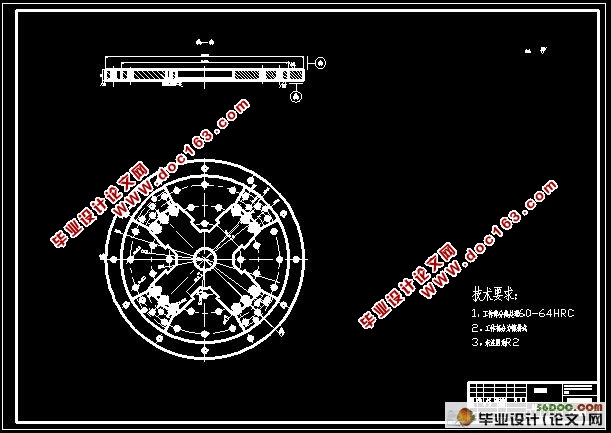

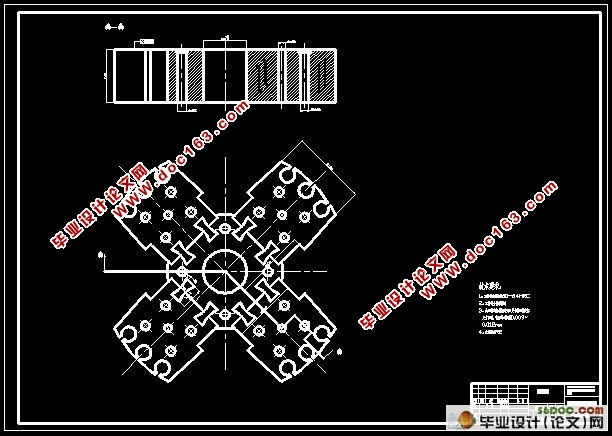

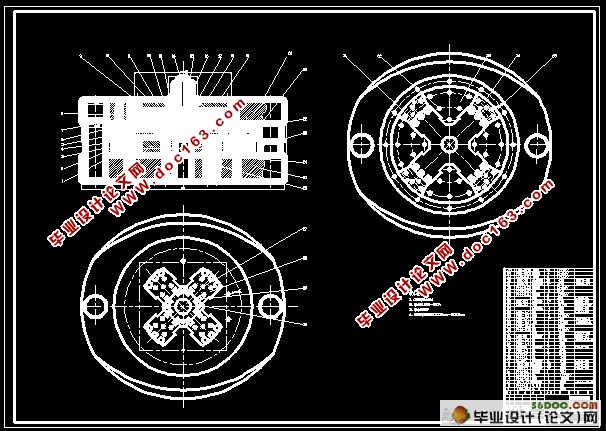

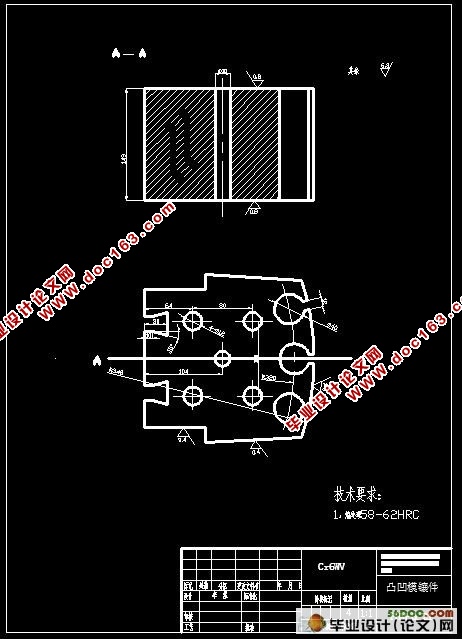

电机转子冲片冲压工艺及模具设计

电机转子冲片冲压工艺及模具设计(包含选题审批表,任务书,开题报告,中期检查报告,毕业论文说明书9000字,成绩评定册,11张cad图)

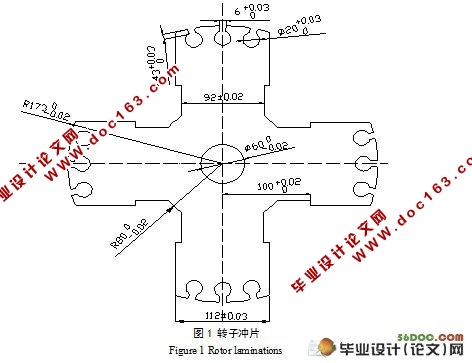

摘要:本文针对目前电机转子设计现状,结合模具结构特点和冲压件的成形工艺性来确定该转子冲片的冲压成形工艺过程。介绍了电机转子冲片的冲压工艺设计,包括工序尺寸的确定和模具设计、制造。通过对一个外形似风扇叶状的薄片零件进行冲载,说明冲载的计算方法,并用该计算确定合理的冲载工艺规程,并以此设计出满足工件要求的冲载模具。

关键词:电机转子;模具;冲压工艺

The Stamping Process And Mold Design of The Electrical Machinery Rotor-sheet

Abstract:This rotor design for the present situation, combined with structural features and stamping die forming process of determining the rotor laminations of metal forming processes. Description of the motor rotor laminations of stamping process design, including process and mold design to determine the size and manufacturing. Shape like a fan through the thin leafy parts for blanking, blanking the calculation shows, and use the calculation to determine a reasonable blanking process planning, and this piece is designed to meet the requirements of the blanking die.

[资料来源:http://www.doc163.com]

Key words:Rotor; die; stamping process

本设计的零件主要应用于机电方面,电机转自冲片是一个冲压件的生产任务后,首先需要熟悉原始资料,透彻地了解产品的各种要求,为此后的冲压工艺设计掌握充分的依据。掌握了原始资料以后,冲压工艺设计可按以下步骤进行。应说明的是,各项内容是互相联系、互相制约,因而各设计步骤应前后兼顾和呼应,有时要互相穿插进行。

1.冲压件工艺性分析

2.确定最佳工艺方案

3.完成工艺计算

4.合理选用冲压设备

5.选定模具结构类型

以上工作都完成以后接下就是便携工艺文件和设计计算说明书了。 [资料来源:Doc163.com]