基于PLC控制的选煤传送带系统的设计(西门子S7-200)

摘要

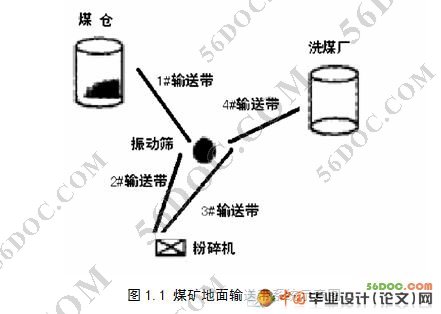

本文介绍了选煤的意义和作用,同时介绍了基于PLC的自动选煤系统的实现。为了保证输送带运输的安全可靠运行,达到减人提效的目的,应用PLC可编程控制器,辅以必要的装置,设计了输送带自动运输系统。煤块从煤仓出来经过1#输送带送到振动筛,在经过振动筛筛选后小的煤块漏到4#输送带送进洗煤厂,大的煤块则经过3#输送带运送到粉碎机,经过粉碎机粉碎后在经过2#输送带到达4#输送带,再输送到洗煤厂。粉碎机由三个限位开关监管,若煤块过多,则将信号传给由PLC控制的变频器,变频器则调节1#输送带的给煤速度。启动有手动和自动两种,自动可自动完成输送任务;手动可单独运行单一电机,达到维修目的。

关键词 : PLC,输送带,振动筛,粉碎机,变频器

Abstract

This article describes the significance and usage of coal preparation, also introduced automated Preparation System based on PLC. To ensure safe and reliable, and to realize the aim of high efficiency we designed the conveyor belt automatic transport system base on PLC programmable controller, addition with the necessary equipment. Coal from the bunker out of conveyor belt through 1 # sent vibrating screen, vibrating screen, after screening a small leak to 4 # coal conveyor belt feeding coal washing plant, a large coal conveyor belt is transported through the 3 # grinding machine, after smash after arrival, after 2 # and 4 # conveyor belts, territory to coal washing plant. Mill consists of three limit switch monitoring, if too much coal, it will signal transmitted by the PLC-controlled inverter, inverter # 1 is regulating the speed coal conveyor belt. Start with manual or automatic, automatic transmission tasks can be done automatically; manual single motor can be run separately, to maintenance purposes. [资料来源:https://www.doc163.com]

Keywords :PLC, conveyor belt, vibrating screen, crusher, inverter

[资料来源:https://www.doc163.com]

[版权所有:http://DOC163.com]

[版权所有:http://DOC163.com]

目录 21000字

摘要 II

前言 - 1 -

第1章PLC原理介绍及总体结构介绍 - 2 -

1.1 PLC发展历程及选题意义 - 2 -

1.2 PLC控制系统设计的基本原则 - 4 -

1.2.1 最大限度地满足被控对象的控制要求 - 4 -

1.2.2. 保证PLC控制系统安全可靠 - 4 -

1.2.3 力求简单、经济、使用及维修方便 - 5 -

1.2.4适应发展的需要 - 5 -

1.3 可编程序控制器PLC的分类 - 5 -

1.4 CPU的构成 - 7 -

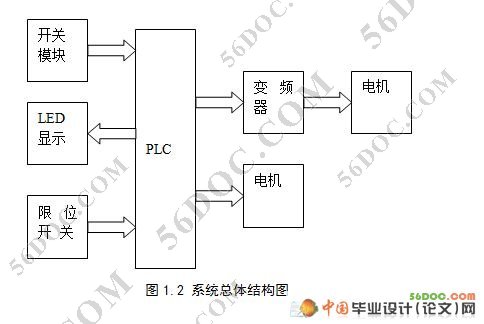

1.5 系统总体结构图 - 8 -

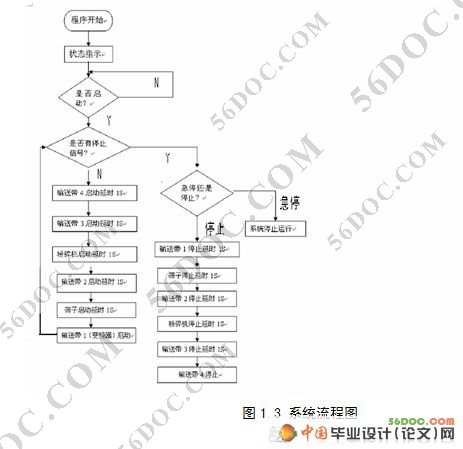

1.6工作流程图 - 10 -

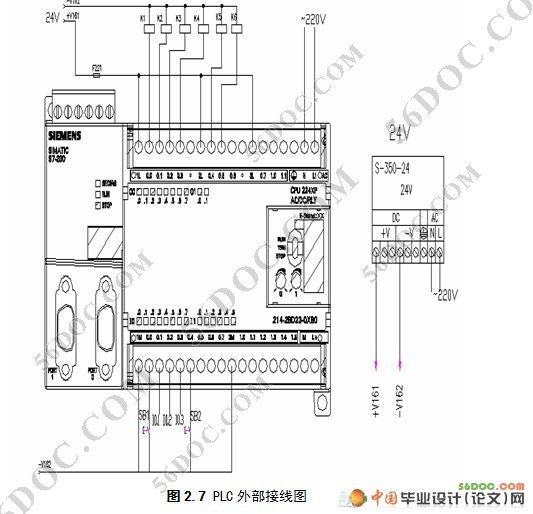

第2章 硬件电路设计 - 11 -

2.1硬件选型 - 11 -

2.1.1 PLC选型 - 11 -

2.1.2 电机的选型 - 18 -

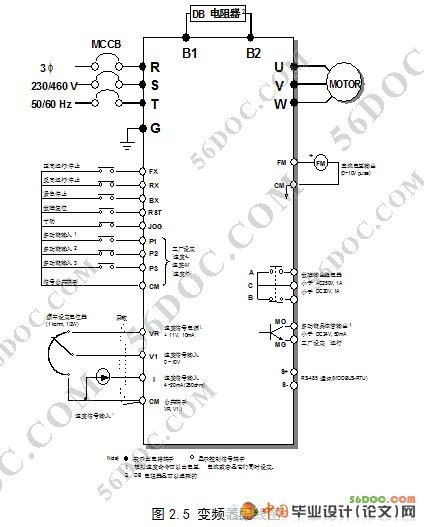

2.1.3 变频器的选型 - 20 -

2.2 控制电路 - 23 -

2.3 主电路图 - 24 -

第3章 系统的软件设计 - 26 -

3.1 STEP7编程软件介绍 - 26 -

3.1.1 STEP7-Mirco/WIN的安装 - 26 -

3.1.2 STEP7-Mirco/WIN窗口组件 - 28 -

3.2 PLC编程语言的基本指令系统和编程方法 - 33 -

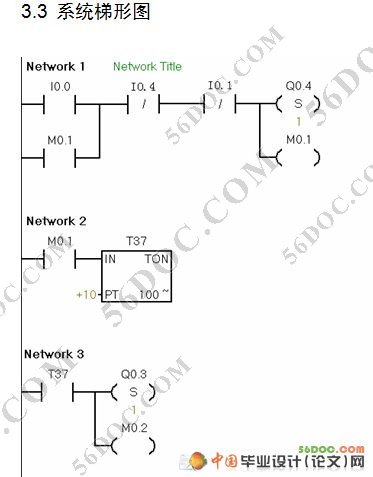

3.3 系统梯形图 - 36 -

3.4 I/O分配表 - 40 -

总结 - 41 -

参考文献 - 43 -

致谢 - 44 - [资料来源:http://www.doc163.com]

下一篇:基于PLC的电机故障诊断系统设计论文(西门子S7-200)