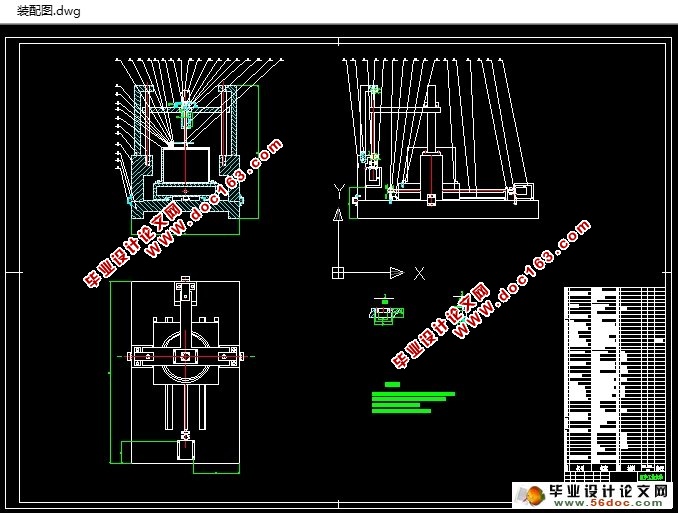

基于自动控制环槽内径检具设计(CAD,CAXA,电路图,程序)

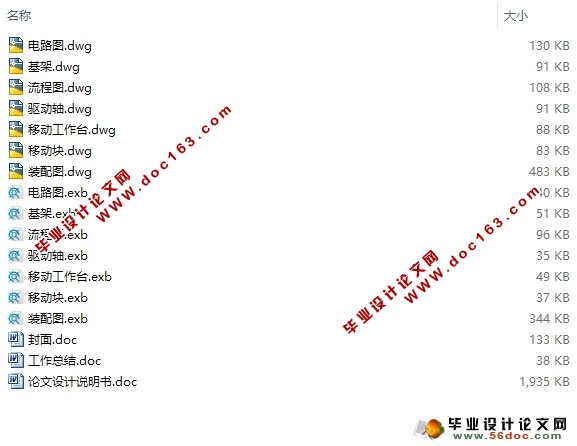

基于自动控制环槽内径检具设计(CAD,CAXA,电路图,程序)(论文设计说明书12500字,工作总结,CAD图7张,CAXA图7张)

摘 要

本次毕业设计是基于自动控制环槽内径检具。它含有机座,移动工作台,升降工作台,驱动轴,传感器和摆杆等。摆杆被固定在检具体上,检具体于驱动轴相连。被测工件通过挡块被固定在移动工作台上。升降工作台上有步进电动机,电动机的主轴线与被测工件中心线重合,步进电机输出轴上接有驱动轴。驱动轴与检具体相连。检具体上有滑动块,上面有传感器,摆杆,电磁继电器和弹簧,升降工作台上的电机转动带动驱动轴转动进而带动摆杆转动完成检测,电磁继电器是为了改变摆杆位置的,能使摆杆自由进入内径。当上方内径检测完毕后,控制升降工作台的步进电动机开始工作,使升降工作台继续下降到达底端的内径进行检测。在机架后端有限位开关,是防止移动过坐台移动太多移到导轨外或指定位置。因为导轨主要是承重用的,所以与机架做成一体。利用检具对环槽内径进行检测,不仅测量精度高、大大的减少人力的浪费,而且适用于测量筒状物体的内圆直径。

关键词:自动控制;环槽内径;检具

Abstract

This is a class-based automatic control loop based on a groove diameter of the seizure. It contains a base, mobile workbench, table movements, driveshaft, such as sensors and swing rod. Swing rod was fixed at Frederick Specifically, the prosecution specifically linked to the driveshaft。Measured part was fixed through the block work in the mobile platform. Table movements are stepper motors, electric motors and the main axis of the center line measured part a coincidence, stepper motor output shaft then there driveshaft. Driveshaft linked to the seizure of specific。Frederick concrete blocks have a slide, there are sensors, placed under, electromagnetic relays and spring, lifting table driven rotating driveshaft of the motor rotating rod before turning to lead the completion of testing, electromagnetic relays before in order to change the location of stroke, allow free access to swing rod diameter. When the top diameter after detection, control movements of the stepper motor to start table work table continued to decline to reach take-off and landing at the bottom of test diameter。Limited spaces in the rack back-end switch is to prevent too much movement坐台moved outside to the rail or the specified location. Because the guide is mainly used in load-bearing, so make one with the rack. Benefit of the design diameter of the ring groove to detect, not only of high measurement accuracy, significantly less of the home of a waste of manpower, but also applies to measuring objects with tubular diameter。

Key words:Automatic Control;Ring groove diameter;Testing instrument

[来源:http://Doc163.com]

目 录

第1章 绪 论 1

1.1 设计背景 1

1.2 环槽内径检测的工作过程 1

第2章 设计方案的确定 2

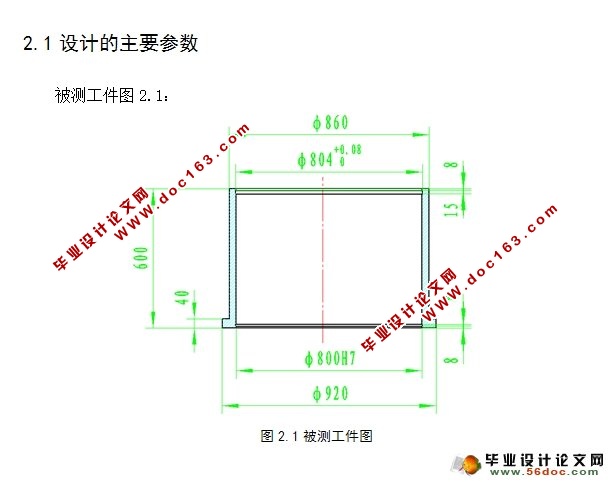

2.1 设计的主要参数 2

2.2 方案确定 2

第3章 机械系统设计 4

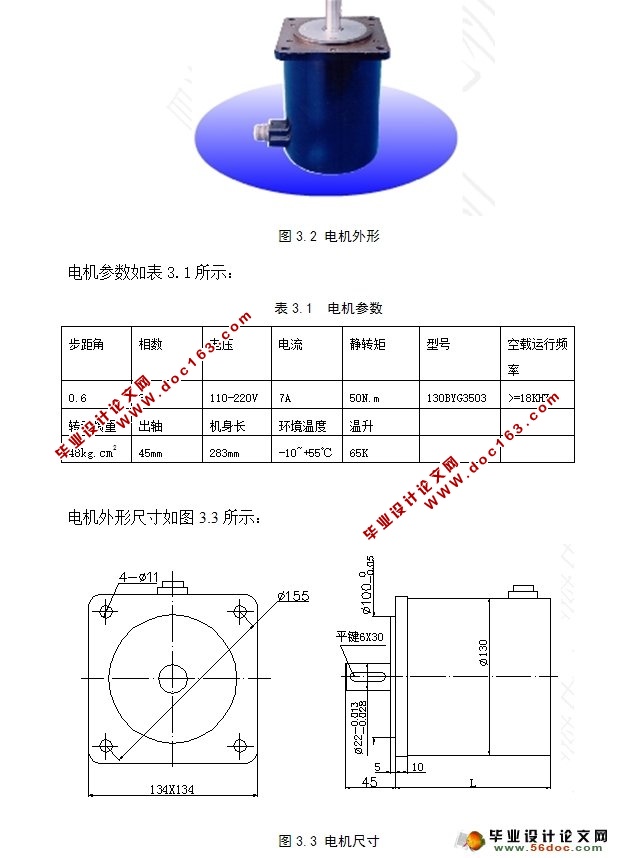

3.1 步进电动机的选择 4

3.1.1 控制移动工作台的步进电动机的选择 4

3.1.2 控制升降台工作的步进电动机的选择 8

3.1.3 控制驱动轴转动的步进电动机的选择 10

3.2 丝杠的选择 14

3.3 驱动轴的选择 23

3.4 轴承的选择 26

3.5 基座的设计 27

3.6 传感器安装设计 28

3.7 限位开关的安装设计 29

3.8 电磁继电器的安装设计 29

3.9 光轴支架和电机支架的设计 29

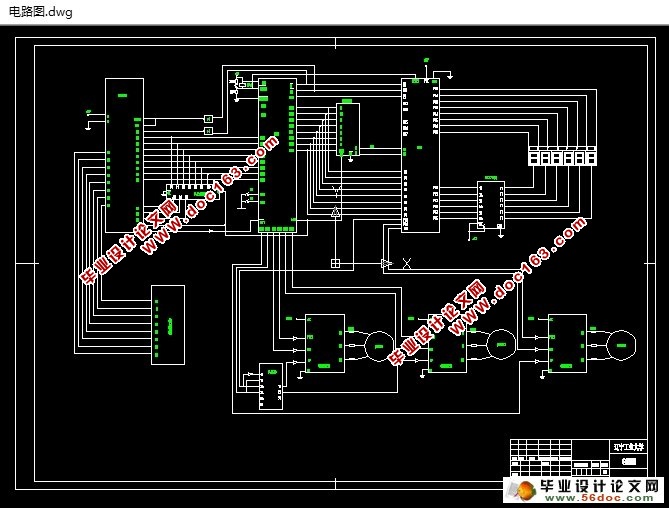

第4章 控制系统设计 31

4.1 控制电路的硬件设计 31

[资料来源:www.doc163.com]

4.2 控制电路的软件设计 34

4.2.1 主程序图框 34

4.2.2 复位程序设计 34

4.2.3动态显示设计 36

第5章 结 论 38

参考文献 39

致 谢 40

附 录I 41

附 录Ⅱ 48

[资料来源:http://Doc163.com]

上一篇:两孔轴线平行度自动测量装置的设计